- Introduction and Overview of 16 Gauge Square Tubing

- Material Composition and Technical Advantages

- Comparative Data: 12, 11, and 18 Gauge Square Tubing

- Industry Suppliers and Manufacturer Comparison

- Customization Options and Engineering Solutions

- Real-World Applications Across Industries

- Conclusion: Selecting the Right 16 Gauge Square Tubing

(16 gauge square tubing)

Introduction and Overview of 16 Gauge Square Tubing

16 gauge square tubing

is a vital structural component used in a broad spectrum of industries, ranging from construction and automotive to furniture and agricultural machinery. Produced primarily from high-strength, cold-rolled steel, this tubing balances formability with durability, making it a preferred choice where weight, strength, and versatility are key criteria. Featuring a nominal wall thickness of 0.065 inches (1.65 mm), 16 gauge square tubing offers outstanding mechanical properties suitable for load-bearing frameworks. In this article, the role of 16 gauge, alongside comparable materials such as 12 gauge square tubing (thicker), 11 gauge square tubing (the thickest), and 18 gauge square tubing (thinner), is explored in-depth to showcase their unique strengths, technical data, customization capabilities, and market options.

Material Composition and Technical Advantages

The composition of 16 gauge square tubing largely defines its performance. Leading manufacturers utilize cold-formed steel grades like ASTM A500 or A513, which guarantee dimensional precision, uniform wall thickness, and robust weldability. Key advantages include:

- Strength-to-weight ratio: 16 gauge provides excellent support while keeping structural dead load minimal, supporting approximately 18,000 to 21,000 psi yield strength depending on the grade.

- Formability: Mild steel content ensures ease of cutting, drilling, and welding, suiting complex assembly requirements.

- Corrosion Resistance: Options include galvanized or pre-painted coatings, resisting oxidation in outdoor or humid environments.

- Precision: Manufacturing processes and tight tolerances deliver straightness and clean edges, reducing downstream fabrication waste.

- Sustainability: Steel square tubing is highly recyclable, with over 70% being produced from recycled materials according to the World Steel Association’s 2022 report.

These factors collectively deliver technical reliability in dynamically loaded structures as well as aesthetics for visible building elements.

Comparative Data: 12, 11, and 18 Gauge Square Tubing

The choice between 16 gauge, 12 gauge, 11 gauge, and 18 gauge square tubing ultimately depends on the required balance between structural load, wall thickness, and weight. Here’s a table highlighting critical dimensions, weight, and mechanical specifications:

| Property |

18 Gauge Square Tubing |

16 Gauge Square Tubing |

12 Gauge Square Tubing |

11 Gauge Square Tubing |

| Wall Thickness (in) |

0.049 |

0.065 |

0.109 |

0.120 |

| Weight per Ft (1" x 1") |

0.58 lbs |

0.83 lbs |

1.31 lbs |

1.44 lbs |

| Yield Strength (psi) |

~17,000 |

~20,000 |

~24,000 |

~25,000 |

| Typical Application Load |

Light bracing, displays |

Medium-duty frames |

Heavy-duty supports |

Maximum load posts |

| Minimum Radius Bend (in) |

1.5 |

2 |

3 |

3.5 |

| Cost Index (USD/lb) |

0.92 |

0.88 |

0.84 |

0.82 |

Thinner gauges, such as 18 gauge, are optimal for light fabrication, while 11 and 12 gauge tubes are chosen for demanding, load-bearing applications. The 16 gauge is recognized for its all-purpose versatility and moderate cost, making it an industry mainstay.

Industry Suppliers and Manufacturer Comparison

Sourcing quality square tubing involves evaluating international and domestic manufacturers on multiple fronts, including certification, consistency, lead times, and service. The following table summarizes key benchmarks among leading suppliers:

| Supplier |

Primary Region |

MOQ (feet) |

Lead Time (days) |

Certifications |

Tinkinimas |

| Allied Tube & Conduit |

USA |

400 |

7-12 |

ASTM, ISO 9001 |

Yes (sizes, coatings, lengths) |

| Valmont Tubing |

USA |

1000 |

10-14 |

ASTM, CSA, ISO |

Yes (profiling, strength grades) |

| JFE Steel |

Japan |

500 |

14-18 |

JIS, ISO |

Yes (surface, precision) |

| Tianjin Youfa |

China |

3000 |

18-24 |

EN, ISO, API |

Yes (large volumes, overseas shipping) |

Domestic suppliers typically offer tighter tolerances and faster delivery for custom orders, while international manufacturers excel in volume pricing and specialized coatings or finishes. Certifications such as ASTM A500 and ISO 9001 should be prioritized for guaranteed material quality and traceability.

Customization Options and Engineering Solutions

To address specific engineering requirements, manufacturers offer a wide variety of customization services for square tubing. This includes alterations in dimensions (from ¾" to 8" square profiles), wall thickness (16 gauge to 7 gauge), and length (cut-to-size from 1’ to 24’). Beyond physical dimensions, users can specify different steel grades for enhanced strength (up to 50 ksi yield or higher), as well as surface treatments:

- Galvanizing for marine and outdoor corrosion resistance

- Powder coating or painting for aesthetic integration

- Pre-punched or slotted holes for rapid on-site assembly

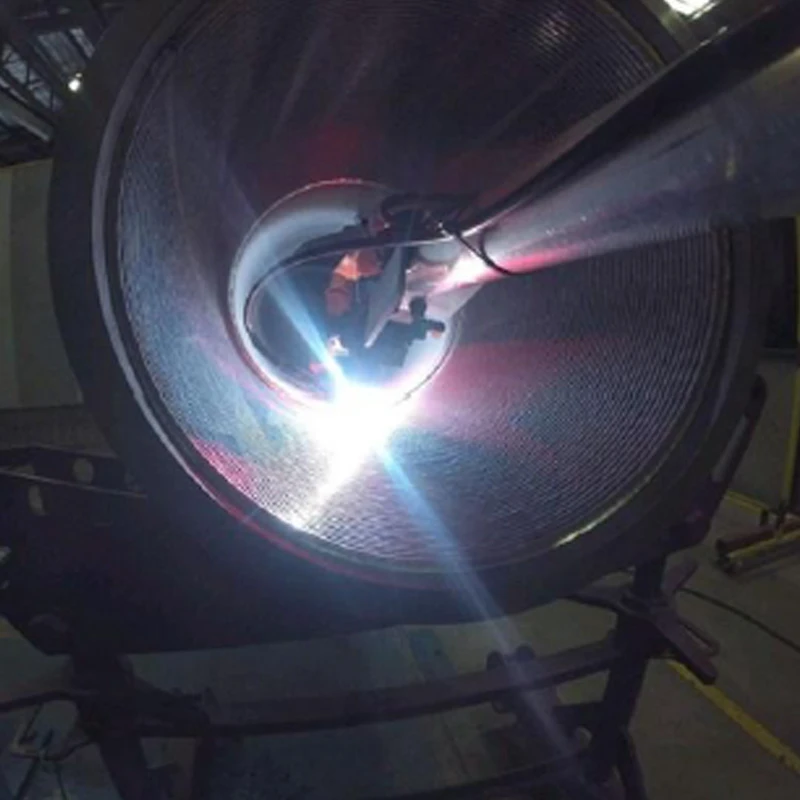

Advanced fabrication can also involve laser cutting, robotic welding, and CNC bending to support intricate frame assemblies for end-users in transportation, architecture, or energy. For construction contractors, pre-engineered kits lessens on-site labor and improves overall project efficiency.

Real-World Applications Across Industries

The adaptability of 16 gauge square tubing is demonstrated across many critical industrial sectors:

- Construction: Used in window frames, railings, scaffold bracing, and lightweight roof trusses. In North America, square tubing supports millions of linear feet annually.

- Automotive: Chassis frames and support brackets leverage 16 gauge for impact resistance and manufacturing ease. According to the U.S. Bureau of Transportation Statistics (2023), 70% of light vehicle frame designs specified 16 or 12 gauge tubing.

- Agricultural: Implements including animal pens, trellises, and greenhouse frameworks use square tubing for weather-resistant durability.

- Furniture Manufacturing: Modern minimalist and industrial-style designs often require high-strength, low-profile square tubing for desks, chairs, and shelving.

- Renewable Energy: Mounting racks for solar panels benefit from a balance of cost, strength, and corrosion protection achievable with galvanized 16 gauge profiles.

These cases prove that this material not only meets, but exceeds, rigorous specification demands across disciplines.

Conclusion: Selecting the Right 16 Gauge Square Tubing

Choosing the optimal 16 gauge square tubing integrates both engineering demands and cost-efficiency. With wall thicknesses, consistent grade options, and broad availability, it stands out as a structural staple alongside alternatives like 12, 11, or 18 gauge square tubing. Whether for demanding load-bearing frames or cost-sensitive project prototypes, precise selection based on yield strength, fabrication preferences, and supplier value is essential. When supported by reputable manufacturing partners and tailored custom solutions, 16 gauge square tubing ensures resilient, future-ready infrastructure across an array of modern industries.

(16 gauge square tubing)

FAQS on 16 gauge square tubing

Q: What is 16 gauge square tubing commonly used for?

A: 16 gauge square tubing is often used in lightweight structural applications like frames, racks, and furniture. Its moderate thickness offers a balance between strength and weight. It's also popular in automotive and DIY projects.

Q: How does 12 gauge square tubing compare to 16 gauge in terms of strength?

A: 12 gauge square tubing is thicker and stronger than 16 gauge tubing. It is ideal for heavy-duty structural projects requiring greater load-bearing capacity. This makes it a preferred choice for construction and industrial frameworks.

Q: Can 18 gauge square tubing be welded easily?

A: Yes, 18 gauge square tubing can be welded, but its thinner walls require careful handling. Lower heat settings and appropriate techniques help prevent burn-through. It's best suited for projects with low-stress requirements.

Q: What are the main applications for 11 gauge square tubing?

A: 11 gauge square tubing is used in applications demanding superior strength, such as support columns and trailer frames. Its thick walls provide excellent resistance to deformation and high loads. It's commonly found in heavy equipment and construction.

Q: How do you choose the right gauge for your square tubing project?

A: Consider the load requirements and intended use to determine the appropriate gauge—for light projects, 16 or 18 gauge may suffice. For heavy duty or structural purposes, opt for 12 or 11 gauge. Thicker tubing offers more strength but adds weight and cost.