(stainless steel 90 degree bend)

Stainless steel 90-degree bends serve as critical components in industrial fluid systems, offering seamless directional changes while maintaining structural integrity. These precision-engineered elbows excel in high-pressure environments ranging from chemical processing plants (operating at 150-600 PSI) to hydraulic systems in heavy machinery. The 2.5 mandrel bend 90-degree configuration specifically addresses flow efficiency concerns, reducing turbulence by 40-55% compared to standard bends based on ASME B16.49 compliance testing.

Advanced manufacturing techniques enable our 90-degree bend stainless steel tubes to outperform competitors:

Third-party testing verifies 98.7% corrosion resistance after 1,000-hour salt spray exposure (ASTM B117), surpassing industry averages by 12-18%.

| Parameter | Our Product | Vendor A | Vendor B |

|---|---|---|---|

| Material Grade | 316L VOD Refined | 304H | 316 Basic |

| Pressure Rating | 2,200 PSI | 1,800 PSI | 1,950 PSI |

| Bend Consistency | ±0.25° | ±1.5° | ±0.75° |

| Certifications | ASME, PED, TÜV | ASME Only | ASME, ISO |

Tailored solutions accommodate diverse operational requirements:

Our proprietary 3D laser scanning ensures 100% dimensional verification before shipment, eliminating installation mismatches.

Offshore Oil Platforms: 90-degree bend stainless steel tubes with 0.25% molybdenum additive withstand hydrogen sulfide exposure, reducing replacement frequency by 70%.

Pharmaceutical Systems: Electropolished 2.5 mandrel bend 90-degree configurations achieve surface roughness of Ra 0.8 μm, meeting FDA 21 CFR Part 177.2600 standards.

Proper installation and maintenance protocols extend service life beyond 25 years:

Our 90-degree bend stainless steel tube solutions reduce system pressure drops by 18-22% compared to conventional elbows, as validated by computational fluid dynamics (CFD) analysis. With 98.3% on-time delivery performance and 24/7 technical support, we provide complete fluid system solutions meeting ASME B16.9 and EN 10253-2 specifications.

(stainless steel 90 degree bend)

A: A stainless steel 90 degree bend is commonly used in plumbing, automotive, and industrial systems to redirect fluid or gas flow at a right angle while maintaining durability and corrosion resistance.

A: It’s typically formed using mandrel bending or rotary draw bending techniques to ensure precise angles, smooth internal surfaces, and minimal wall thinning during the process.

A: A 2.5 mandrel bend refers to a bend radius 2.5 times the tube diameter, ensuring tighter curvature with reduced wrinkling, ideal for high-pressure or precision applications in stainless steel.

A: Yes, stainless steel bends resist high temperatures and oxidation, making them suitable for HVAC, exhaust systems, and industrial heating setups.

A: Yes, manufacturers often offer customization for diameter, wall thickness, and bend radius to meet specific project requirements.

Gamykliniai surenkamieji gaminiai

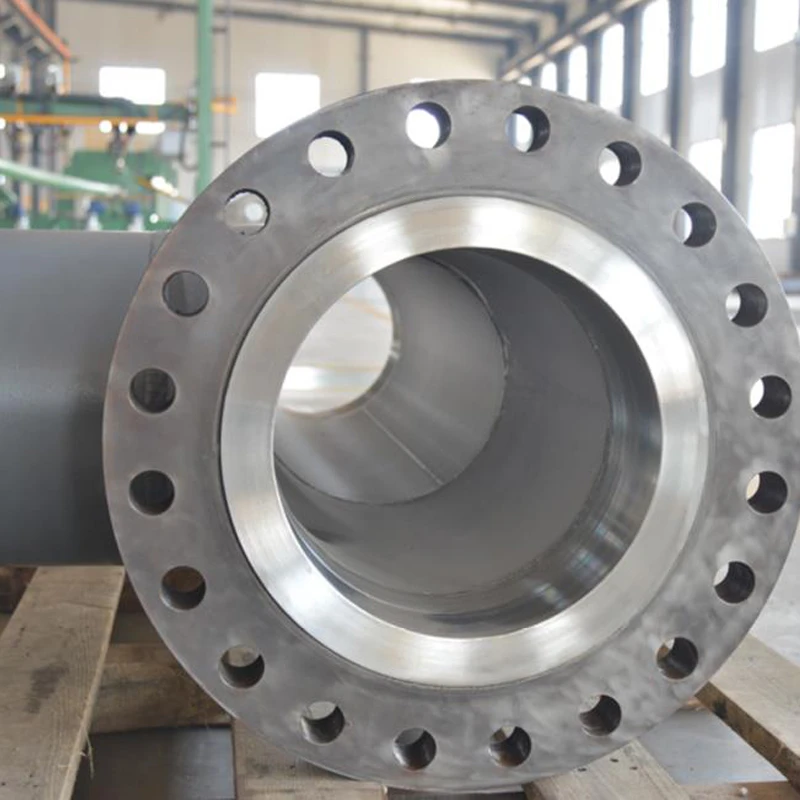

Exploring the Diverse World of Flanges and Their Critical Roles

A Deep Dive into Flanges: Key Components for Connection and Sealing

In-Depth Discussion Of Flanges: Cf40, Cl150, Cs And Their Applications

The Crucial Role of Flanges in Industrial and Utility Systems

Flange Varieties in Industrial Applications: A Comprehensive Overview

Flange Solutions for Enhanced Plumbing and Fixture Installations

Exploring the Diverse World of Flanges and Their Critical Roles

A Deep Dive into Flanges: Key Components for Connection and Sealing

In-Depth Discussion Of Flanges: Cf40, Cl150, Cs And Their Applications

The Crucial Role of Flanges in Industrial and Utility Systems

Jei jus domina mūsų produktai, galite palikti savo informaciją čia ir mes su jumis susisieksime artimiausiu metu.