In the vast and complex world of industrial infrastructure, maintaining the integrity and efficiency of piping systems is paramount. At the heart of this reliability are flanges, critical components used to connect pipes, valves, pumps, and other equipment to form a cohesive and leak-free system. A metal flange is designed to provide easy access for cleaning, inspection, or modification, offering a robust and dependable connection that can withstand diverse operational pressures and temperatures. From the harsh environments of petrochemical plants to the precise demands of pharmaceutical manufacturing, the right flange ensures operational safety and longevity.

The selection of an appropriate flange depends heavily on specific application requirements, including material compatibility, pressure rating, temperature range, and the nature of the fluid being transported. Different types of flanges are engineered to meet unique challenges, from preventing leaks in high-pressure steam lines to accommodating thermal expansion in dynamic systems. Understanding the intricacies of these components is vital for engineers and procurement specialists aiming to optimize system performance and minimize downtime.

The production of a high-quality metal flange involves a meticulously controlled process to ensure structural integrity and dimensional accuracy. The journey begins with selecting the optimal material, which can range from carbon steel (e.g., ASTM A105, A350 LF2) for general industrial applications to specialized alloy steels (e.g., ASTM A182 F5, F11, F22) and stainless steel flange materials (e.g., ASTM A182 F304/304L, F316/316L) for corrosive or high-temperature environments. Each material is chosen for its specific properties, such as tensile strength, yield strength, and resistance to corrosion and creep.

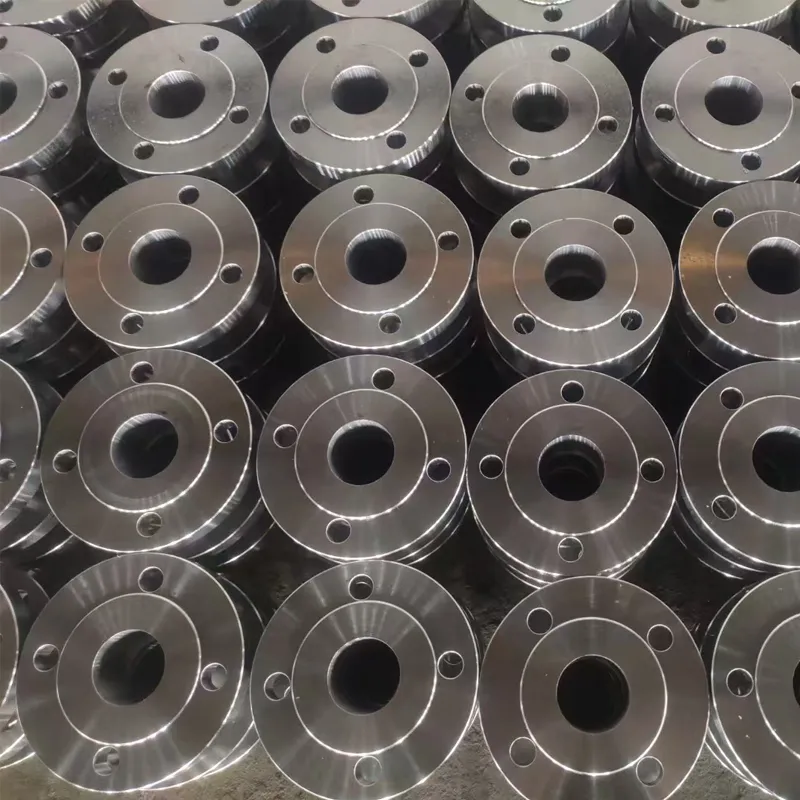

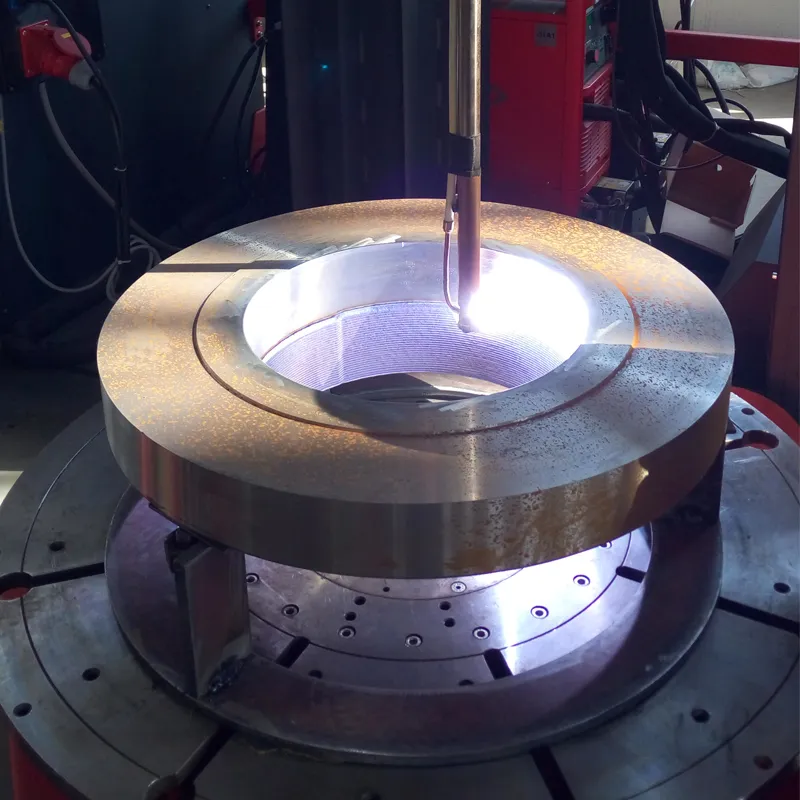

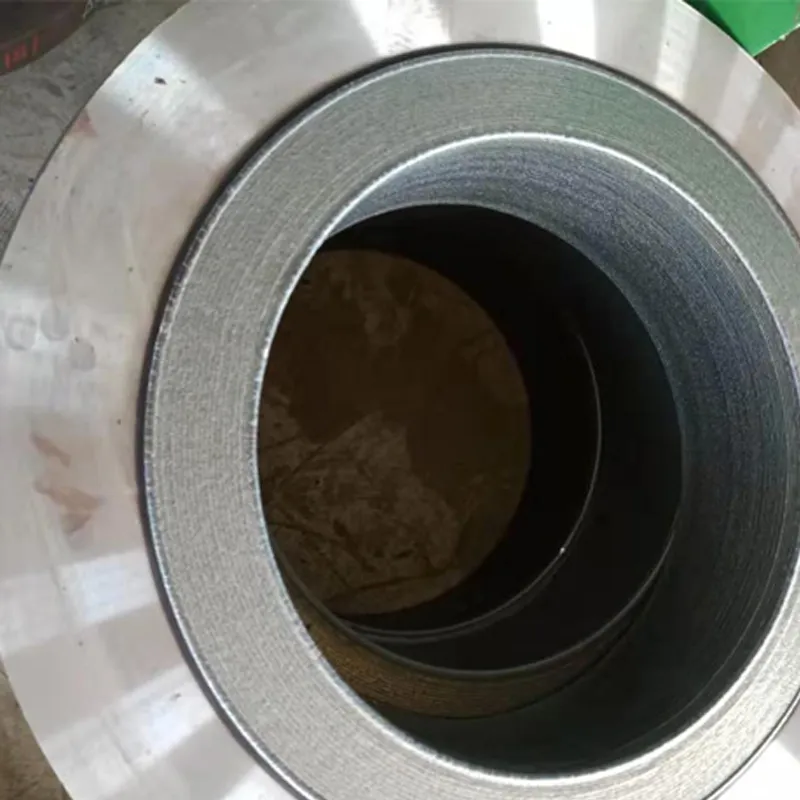

Key manufacturing processes include forging, casting, and machining. Forging, typically performed through open die or closed die methods, involves shaping metal under extreme pressure and heat, resulting in superior grain structure and enhanced mechanical properties, making the metal flange more robust and less prone to defects. Casting, on the other hand, involves pouring molten metal into a mold, suitable for more intricate shapes. Following the primary forming process, advanced CNC machining ensures precise dimensions, smooth surface finishes, and accurate bolt hole alignment, crucial for effective sealing and installation.

Quality control is integrated at every stage, from raw material inspection to final product verification. This includes non-destructive testing (NDT) methods like ultrasonic testing, magnetic particle inspection, and radiographic testing to detect internal flaws. Flanges must adhere to stringent international standards such as ISO (International Organization for Standardization) and ANSI/ASME (American National Standards Institute/American Society of Mechanical Engineers) to guarantee interchangeability, performance, and safety. A typical metal flange, manufactured under these strict controls, is designed for a service life exceeding 20 years under normal operating conditions, making them a sustainable investment.

Understanding the technical parameters and adhering to industry standards are critical for selecting the correct metal flange. Key parameters include Nominal Pipe Size (NPS), pressure rating (Class or PN), and facing type. NPS defines the pipe's approximate diameter. Pressure ratings, such as Class 150, 300, 600, or PN10, PN16, PN25, indicate the maximum allowable pressure a flange can withstand at specific temperatures. Different facing types like Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ), or Lap Joint (LJ) are selected based on gasket type and sealing requirements.

| Standard / Material | Nominal Pipe Size (NPS) | Pressure Class (lbs) | Temperature Range (°C) | Typical Application |

|---|---|---|---|---|

| ASME B16.5 / Carbon Steel (A105) | 1/2" - 24" | 150 - 2500 | -29 to 425 | General industrial, water, oil & gas |

| ASME B16.5 / Stainless Steel (F316L) | 1/2" - 24" | 150 - 2500 | -196 to 538 | Corrosive environments, chemical, food processing |

| DIN / PN Series (EN 1092-1) | DN10 - DN1200 | PN6 - PN100 | -10 to 400 | European industrial applications |

Compliance with standards like ANSI/ASME B16.5 (for pipe flanges and flanged fittings) or ASME B16.47 (for large diameter steel flanges) ensures compatibility across different manufacturers and prevents costly mistakes in piping system assembly. These standards dictate dimensions, pressure-temperature ratings, materials, tolerances, marking, and testing methods. Selecting a supplier with a proven track record of adherence to these standards is crucial for guaranteeing the integrity and safety of your operations.

The versatility of the metal flange makes it indispensable across a multitude of industries. In the petrochemical and oil & gas sectors, flanges facilitate the transportation of crude oil, natural gas, and refined products under extreme pressures and temperatures, often requiring specialized materials like alloy steels for enhanced corrosion and heat resistance. For water supply and drainage systems, as well as water treatment plants, carbon steel and stainless steel flange types are common due to their resistance to water-induced corrosion and long service life. The metallurgical industry relies on robust flanges for high-temperature and abrasive material handling.

Beyond basic connectivity, advanced flange designs offer specific advantages. For instance, an offset flange might be utilized in situations where precise alignment is challenging or to accommodate minor pipe misalignments, streamlining installation and reducing stress on the piping system. Similarly, a flexible flange, often incorporating bellows or expansion joints, is crucial in systems subject to significant thermal expansion, vibration, or seismic activity. These specialized flanges absorb movement, reduce stress, and prevent damage, thereby enhancing system longevity and safety.

The inherent advantages of using properly specified flanges are significant. They enable efficient energy transfer by minimizing leaks, which translates into substantial energy savings over time. Their robust design ensures long-term corrosion resistance, especially with appropriate material selection and coatings, drastically reducing maintenance costs and preventing environmental contamination. The ability to easily dismantle and reassemble flanged connections facilitates routine inspection and repair, leading to improved operational efficiency and reduced downtime in critical industrial processes.

The variety of flange types available ensures that specific operational needs can be met with precision. Among the different types of flanges, the most common include Weld Neck flanges, which offer excellent stress distribution and are ideal for high-pressure, high-temperature applications; Slip-On flanges, which are easily aligned and used in low-pressure applications; Blind flanges, used to close off the end of a piping system or valve opening; Socket Weld flanges, preferred for small-bore, high-pressure piping; and Threaded flanges, suitable for non-welded applications. Lap Joint flanges are used with stub ends and allow for easy alignment of bolt holes without rotating the pipe. Each type serves a distinct purpose, impacting system integrity and installation complexity.

| Material Type | Typical Grade | Corrosion Resistance | Temperature Range (°C) | Strength | Relative Flange Price |

|---|---|---|---|---|---|

| Carbon Steel | ASTM A105 | Low | -29 to 425 | High | Lowest |

| Low Temp Carbon Steel | ASTM A350 LF2 | Low | -46 to 340 | High | Low to Medium |

| Stainless Steel | ASTM A182 F316L | Excellent | -196 to 538 | Medium to High | Medium to High |

| Duplex Stainless Steel | ASTM A182 F51 | Superior | -50 to 300 | Very High | High |

The choice of material significantly influences the overall flange price and performance. While carbon steel flanges are the most cost-effective for general-purpose applications, their limited corrosion resistance necessitates careful consideration in harsh environments. Stainless steel flange varieties, such as 304L and 316L, offer superior corrosion resistance and higher temperature capabilities, justifying their higher initial cost through extended service life and reduced maintenance in chemical processing, marine, and food industries. Alloy steel flanges (e.g., Chrome-Moly) are selected for extreme temperature and pressure conditions, such as those found in power generation and high-pressure oil & gas, where their specialized properties outweigh the premium `flange price`.

Recognizing that standard solutions do not always fit unique industrial challenges, manufacturers offer extensive customization capabilities for metal flange components. This includes tailor-made dimensions, specialized material compositions for extreme environments, unique facing requirements, and specific drilling patterns. Companies with advanced engineering and machining capabilities can produce flanges that precisely meet complex project specifications, ensuring optimal performance and seamless integration into existing or new systems. This bespoke approach minimizes the need for costly field modifications and ensures project timelines are met with precision.

Case studies often highlight the value of custom flange solutions. For instance, in a recent project for a liquefied natural gas (LNG) terminal, a unique offset flange design was required to connect a new pipeline segment to an existing manifold with precise angular alignment challenges, preventing the need for extensive structural rework. In another instance, a client operating a corrosive chemical processing plant required stainless steel flange components with enhanced resistance to specific acids, which were custom-forged and machined to exact specifications, significantly extending the operational life of their piping system and reducing maintenance cycles.

Our approach emphasizes close collaboration with clients from concept to completion. With over two decades of experience in the pipeline component industry, we leverage our expertise in design, manufacturing, and quality assurance to deliver solutions that not only meet but exceed industry standards. Our commitment to innovation ensures that even the most challenging flange requirements are addressed with technical prowess and an understanding of the long-term operational needs of our partners.

In the B2B sector, trust and authority are built on consistent performance and transparent practices. As a leading manufacturer of pipeline components, our dedication to quality is underscored by rigorous certifications, including ISO 9001:2015 for quality management systems and API 6A/6D for specific oil and gas equipment, demonstrating our adherence to global benchmarks. Our products, including every metal flange, undergo comprehensive testing, such as hydrostatic testing to verify pressure integrity and material analysis to confirm chemical composition and mechanical properties, ensuring reliability even under the most demanding conditions.

We are committed to providing exceptional customer support, from initial consultation to after-sales service. Our standard delivery cycle for stock items is typically 3-5 business days, with custom orders fulfilled within 4-6 weeks depending on complexity. All our flanges come with a comprehensive 2-year warranty against manufacturing defects, reflecting our confidence in product durability. We also offer a dedicated technical support team available 24/7 to address any queries or issues, ensuring minimal disruption to your operations.

The metal flange is far more than a simple connector; it is a fundamental pillar of industrial safety, efficiency, and longevity. Its crucial role in securing piping systems, enabling modularity, and facilitating maintenance cannot be overstated. From the initial selection of raw materials to the precision of CNC machining and adherence to stringent international standards, every step in the manufacturing process of a high-quality flange is designed to ensure maximum reliability. As industries evolve and demand higher performance and greater sustainability, the continuous innovation in flange design, including solutions like the flexible flange and advanced material selections, will remain critical. Partnering with a reputable manufacturer that prioritizes engineering excellence, comprehensive testing, and unwavering customer support ensures that your industrial systems operate safely and efficiently for decades to come, optimizing performance and safeguarding investments.

Anti Corrosion And Thermal Insulation Products

Where to Buy Stainless Steel Pipes and Tubing for Sale Together

The Future of Smart Flange Technology

Tee Pipe Fitting in Industrial Process Piping

Prefabricated Pipe in Shipbuilding Applications

How Anti Corrosion Pipe Extends Pipeline Lifespan

Cts Pipe Fittings for Potable Water Systems

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.