In today's demanding industrial landscape, where infrastructure integrity and operational efficiency are paramount, the evolution of piping materials is crucial. Traditional piping often falls short when exposed to corrosive media, extreme temperatures, or abrasive environments. This challenge has driven innovation towards advanced solutions like the composite pipe, a multi-layered structure engineered to combine the strengths of different materials. These pipes offer superior resistance to various degradation mechanisms, ensuring extended service life and reduced maintenance. As a leading composite pipe manufacturer, Lion Pipeline focuses on delivering high-performance solutions that meet the stringent requirements of critical applications across diverse sectors. Our Laser Clad Pipe represents a cutting-edge approach to this technology, providing an unparalleled combination of robustness and specialized surface properties.

The demand for these specialized pipes is escalating across petrochemical, mining, power generation, and wastewater treatment industries, driven by the need for enhanced safety, environmental compliance, and cost-effectiveness. A well-designed composite pipe mitigates risks associated with leaks, material degradation, and frequent replacements, thereby contributing significantly to operational uptime and long-term economic savings. The strategic selection of materials and manufacturing processes ensures that each pipe is optimized for its specific operational challenges, moving beyond the limitations of conventional steel pipe manufacturing. Our expertise allows us to engineer solutions that withstand the most aggressive conditions, setting new benchmarks in performance and reliability.

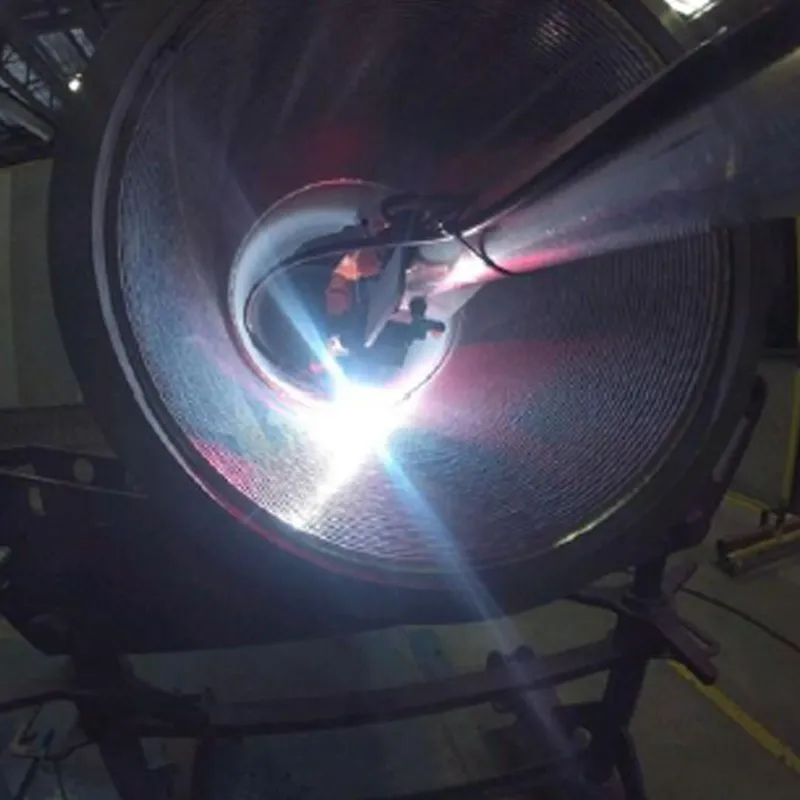

The manufacturing of our Laser Clad Pipe, a superior form of composite pipe, involves a highly sophisticated process known as laser cladding. This advanced metallurgical technique creates a robust, wear-resistant, and corrosion-resistant layer on the internal or external surface of a pipe substrate, typically made from carbon or low-alloy steel. The process begins with meticulous substrate preparation, ensuring a clean and optimal surface for bonding. Specialized alloy powders, often nickel-based, cobalt-based, or stainless steel variants, are precisely fed into a melt pool created by a high-power laser beam. This localized heating melts both the powder and a minimal portion of the substrate surface, forming a metallurgical bond upon solidification.

Unlike traditional welding or thermal spraying, laser cladding results in a dense, pore-free layer with minimal heat-affected zone (HAZ) and low dilution, typically below 5%. This ensures that the clad layer maintains its intended properties without significantly altering the mechanical characteristics of the base material. Post-cladding, pipes undergo strict quality control, including non-destructive testing (NDT) such as ultrasonic testing (UT), eddy current testing, and visual inspections, to verify layer integrity, thickness, and adherence. Our manufacturing facilities adhere to international standards like ISO 9001 and are capable of meeting specific project requirements, ensuring that every composite pipe exhibits exceptional longevity and performance in critical applications within the petrochemical, metallurgy, and water treatment industries, proving superior in terms of corrosion resistance and operational lifespan compared to conventional piping solutions.

The technical prowess of our Laser Clad composite pipe is best illustrated through its specifications. This pipe combines the structural strength of a steel substrate with the specialized surface properties of high-performance alloys. The substrate can be carbon steel (e.g., API 5L Gr. B, X42, X52, X65) or low-alloy steel, providing excellent mechanical integrity. The clad layer, typically ranging from 1.0 mm to 3.0 mm in thickness, is metallurgically bonded and offers unparalleled resistance.

| Parameter | Description / Value | Relevant Standard / Benefit |

|---|---|---|

| Substrate Material | Carbon Steel (e.g., API 5L Gr. B, X42, X52, X65, A106 Gr. B) | High mechanical strength, Cost-effective structural base |

| Cladding Material | Inconel 625, Hastelloy C276, Duplex/Super Duplex SS (e.g., 2205, 2507) | Superior corrosion, erosion, and wear resistance |

| Clad Layer Thickness | 1.0 mm - 3.0 mm (Customizable) | Optimal protection with minimal dilution |

| Metallurgical Bond Strength | Exceeds ASTM G40 standards for bond integrity | No delamination, consistent performance |

| Operating Temperature Range | -50°C to +450°C (depending on materials) | Versatile for various extreme environments |

| Operating Pressure | Up to 3000 PSI+ (as per substrate rating and ASME B31.3/API 5LD) | Suitable for high-pressure applications |

| Corrosion Rate | Negligible in specified corrosive media (e.g., H2S, CO2, chlorides) | Extended lifespan, reduced downtime |

| Service Life Expectancy | 20+ years in optimized conditions | Significant ROI, lower lifecycle costs |

These parameters underscore the engineered superiority of Laser Clad pipes. The synergy between the robust base pipe and the high-performance clad layer translates into a pipe that is not just a component but a long-term asset, reducing total cost of ownership (TCO) by minimizing failures and maintenance. As a professional composite pipe manufacturer, we understand that these specifications are critical for engineers and procurement managers seeking reliable solutions.

When evaluating advanced piping systems, a comparison reveals the distinct advantages of our Laser Clad Pipe as a premier composite pipe solution. Unlike solid alloy pipes, which are prohibitively expensive and often unnecessary for bulk material, or internally lined pipes (e.g., with plastic or fiberglass) that suffer from potential delamination, permeation, or temperature limitations, laser cladding offers a metallurgically bonded solution. This ensures no annular space for fluid permeation, vastly superior temperature and pressure ratings, and exceptional resistance to mechanical damage. This makes it an ideal choice where both structural integrity and extreme corrosion/erosion resistance are simultaneously required.

| Feature | Laser Clad Pipe (Composite) | Internally Lined Pipe (Plastic/FRP) | Solid Alloy Pipe |

|---|---|---|---|

| Corrosion Resistance | Excellent (Metallurgical bond of high alloy) | Good (Limited by liner material, potential permeation) | Excellent (Homogeneous alloy) |

| Wear/Erosion Resistance | Excellent (Dense, hard clad layers) | Poor to Moderate (Soft liners) | Good to Excellent (Depends on alloy) |

| Max Operating Temp. | Up to 450°C+ (Limited by substrate) | Typically below 150°C (Limited by liner) | High (Limited by alloy type) |

| Max Operating Pressure | High (Determined by steel substrate) | Moderate (Can delaminate under pressure) | High |

| Cost-Effectiveness | High (Lower initial cost than solid alloy, long lifespan) | Moderate (Lower initial, higher lifecycle if failures occur) | Low (Very high initial cost) |

| Bonding Integrity | Metallurgical Bond (No delamination risk) | Mechanical/Adhesive (Risk of delamination) | Monolithic |

The application scenarios for these advanced composite pipe solutions are vast and varied. They are indispensable in upstream oil and gas for sour service lines (H2S, CO2), subsea pipelines, and flow lines where highly corrosive fluids are transported. In the chemical processing industry, they handle aggressive acids and alkalis, ensuring process safety and uptime. The mining sector benefits from their superior abrasion resistance for slurry transport. Furthermore, municipal and industrial wastewater treatment plants utilize them for their robust corrosion resistance against biological and chemical effluents. These pipes contribute to significant energy savings by minimizing fluid friction and avoiding frequent system shutdowns for repairs.

Recognizing that no two projects are exactly alike, as a seasoned composite pipe manufacturer, we specialize in providing highly customized Laser Clad Pipe solutions. Our engineering team works closely with clients to understand specific operational parameters, including fluid chemistry, temperature, pressure, flow rates, and environmental conditions. This collaborative approach allows us to recommend the optimal substrate material, cladding alloy (e.g., Inconel 625 for chloride-induced stress corrosion cracking, Hastelloy C276 for extreme acidic environments), and cladding thickness to ensure maximum performance and cost-efficiency. From concept to commissioning, we offer comprehensive support, including material selection, design optimization, and post-installation technical guidance.

Our commitment extends beyond product delivery to ensuring long-term customer satisfaction and trust. As a reputable steel pipe manufacturer and composite pipe specialist, we offer flexible delivery schedules tailored to project timelines, supported by efficient logistics. Every Laser Clad Pipe is backed by a robust warranty against manufacturing defects, reflecting our confidence in our stringent quality control and advanced production techniques. Our dedicated customer support team is always available to provide technical assistance, answer queries regarding maintenance, or assist with future project planning. We pride ourselves on building lasting partnerships based on reliability, quality, and technical excellence, providing peace of mind to our clients globally.

A1: Laser Clad composite pipe is highly beneficial for industries dealing with aggressive media or requiring extended asset life. These include oil and gas (onshore, offshore, subsea), petrochemical, chemical processing, power generation, mining, and wastewater treatment, especially for applications involving sour gas, corrosive chemicals, high temperatures, or abrasive slurries.

A2: Due to its superior corrosion and wear resistance achieved through the metallurgical bond of high-performance alloys, a Laser Clad composite pipe typically offers a significantly longer lifespan, often exceeding 20 years, compared to traditional carbon steel pipes (which might last 5-10 years in corrosive environments) or even internally lined pipes prone to delamination. This translates to substantial lifecycle cost savings.

A3: Our manufacturing process for composite pipe adheres to stringent quality control protocols, including material certifications, in-process monitoring of cladding parameters, and post-cladding non-destructive testing (NDT) such as ultrasonic testing (UT), dye penetrant inspection, and visual inspection. We also perform mechanical tests (e.g., bend tests, hardness tests) and corrosion resistance tests to ensure compliance with international standards like API 5LD and ASME B31.3.

A4: Absolutely. As experienced composite pipe manufacturers, we offer extensive customization options. This includes varying substrate grades and dimensions, selecting specific cladding alloys (e.g., Nickel, Cobalt, Duplex Stainless Steel alloys) to combat particular corrosive or abrasive media, and adjusting cladding thickness. Our engineering team collaborates with clients to design the most effective solution for their unique operational challenges.

Anti Corrosion And Thermal Insulation Products

Where to Buy Stainless Steel Pipes and Tubing for Sale Together

The Future of Smart Flange Technology

Tee Pipe Fitting in Industrial Process Piping

Prefabricated Pipe in Shipbuilding Applications

How Anti Corrosion Pipe Extends Pipeline Lifespan

Cts Pipe Fittings for Potable Water Systems

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.