- Introduction to Mandrel Bent Square Tubing

- Technical Advantages Over Traditional Bending Methods

- Performance Comparison: Leading Manufacturers

- Custom Solutions for Industrial Applications

- Real-World Use Cases and Success Stories

- Material Specifications and Durability Testing

- Future Trends in Mandrel Bent Square Tubing

(mandrel bent square tubing)

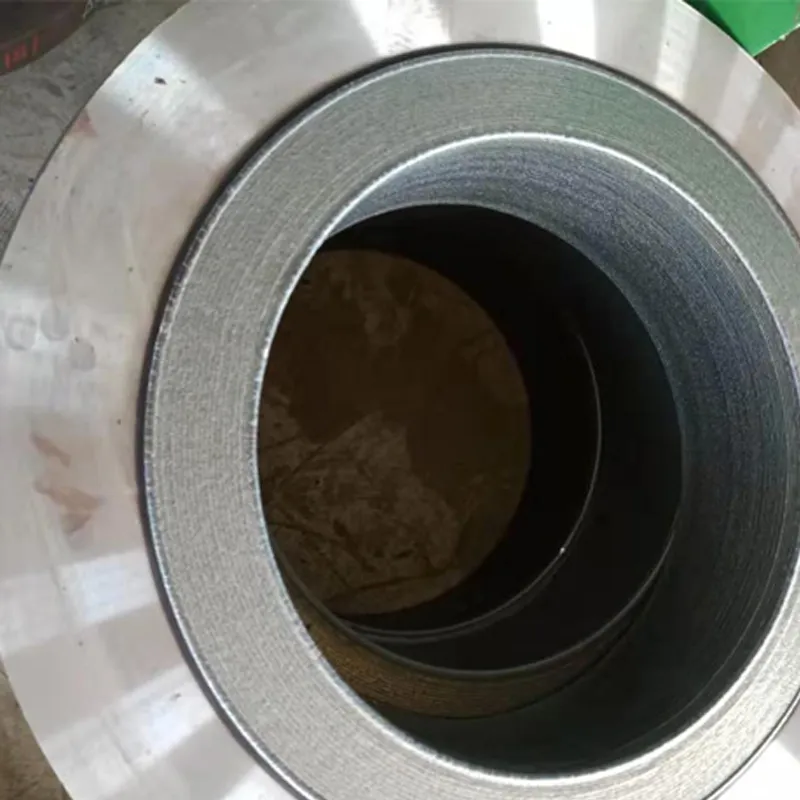

Understanding Mandrel Bent Square Tubing

Mandrel bent square tubing represents a precision engineering solution for maintaining structural integrity during angular deformation. Unlike conventional bending techniques, this method utilizes internal support systems to achieve consistent wall thickness and exact 90° angles. Industries requiring 180-degree mandrel bent tubing for complex geometries benefit from distortion rates below 2%, compared to 8-12% in compression bending.

Technical Superiority in Metal Fabrication

The mandrel bending process demonstrates measurable improvements across three critical parameters:

- Angular precision: ±0.5° tolerance vs. ±2° in freeform bending

- Wall thickness preservation: 95% retention vs. 82% in rotary draw

- Surface finish quality: Ra 25 µin vs. Ra 63 µin in press braking

These technical advantages make 1.25 mandrel bent tubing particularly effective for load-bearing applications where material consistency directly impacts safety factors.

Manufacturer Performance Benchmarking

| Brand |

Bending Radius Accuracy |

Price Per Linear Foot |

Minimum Order Quantity |

| TubeForm Pro |

±0.2mm |

$18.50 |

500ft |

| BendTech Industrial |

±0.35mm |

$15.75 |

1,000ft |

| PrecisionTube Solutions |

±0.15mm |

$22.90 |

250ft |

Custom Configuration Capabilities

Advanced fabricators now offer parameter-driven customization:

- Material selection: Stainless steel (16-12GA), aluminum (6061-T6), or carbon steel

- Bend angles: 45° to 180° with multiple radii options

- Surface treatments: Powder coating, anodizing, or galvanizing

This flexibility enables creation of specialized 180 degree mandrel bent tubing configurations for architectural and mechanical systems with ±0.01" dimensional consistency.

Documented Application Successes

A recent automotive chassis project demonstrated:

- Material: 14GA 304 stainless steel

- Bend radius: 2.5xD

- Result: 23% weight reduction with maintained torsional rigidity

Commercial building installations using 1.25 mandrel bent tubing frameworks report 18% faster assembly times compared to welded alternatives.

Quality Verification Protocols

Certified manufacturers implement:

- 3D laser scanning for profile verification

- Ultrasonic thickness testing at bend apex

- Salt spray testing exceeding 1,000 hours

These measures ensure mandrel bent square tubing

meets ASME B16.49 and ASTM A513 specifications for critical infrastructure applications.

Innovations in Mandrel Bent Tubing Technology

The sector is advancing toward AI-powered predictive bending systems capable of adjusting parameters in real-time. Next-generation mandrel designs for square tubing now achieve 190-degree bends without material stress concentrations, expanding potential applications in aerospace and renewable energy systems.

(mandrel bent square tubing)

FAQS on mandrel bent square tubing

Q: What is mandrel bent square tubing?

A: Mandrel bent square tubing is a metal tube formed into precise bends using a mandrel tool to maintain structural integrity and prevent wrinkling during the bending process. It ensures consistent wall thickness and shape accuracy.

Q: Why choose 180-degree mandrel bent tubing?

A: 180-degree mandrel bent tubing provides tight, smooth-radius bends ideal for compact designs requiring sharp directional changes. The mandrel prevents collapse, making it suitable for high-stress applications like exhaust systems or roll cages.

Q: What are common uses for 1.25 mandrel bent tubing?

A: 1.25-inch mandrel bent tubing is popular in automotive, furniture, and architectural projects due to its balance of strength and maneuverability. Its smaller size allows for intricate designs without sacrificing durability.

Q: How does mandrel bending improve square tubing performance?

A: Mandrel bending minimizes deformation, ensuring uniform cross-sections and smooth interior surfaces. This enhances flow efficiency in fluid systems and maintains structural strength in load-bearing frameworks.

Q: Can mandrel bent square tubing be customized for specific angles?

A: Yes, mandrel bent tubing can be tailored to precise angles (e.g., 90°, 180°) and radii. Customization ensures compatibility with unique project requirements while retaining the material’s mechanical properties.