- Overview of FF Flange Applications in Industrial Systems

- Material Innovation and Durability in Flange Design

- Cost-Effectiveness of Sourcing from Flange China Suppliers

- Technical Specifications: How Leading Manufacturers Compare

- Customization Strategies for Complex Flange Requirements

- Case Study: FF Flange Performance in High-Pressure Environments

- Why Partnering with a Global Flange Exporter Matters

(ff flange)

FF Flange Solutions for Modern Industrial Demands

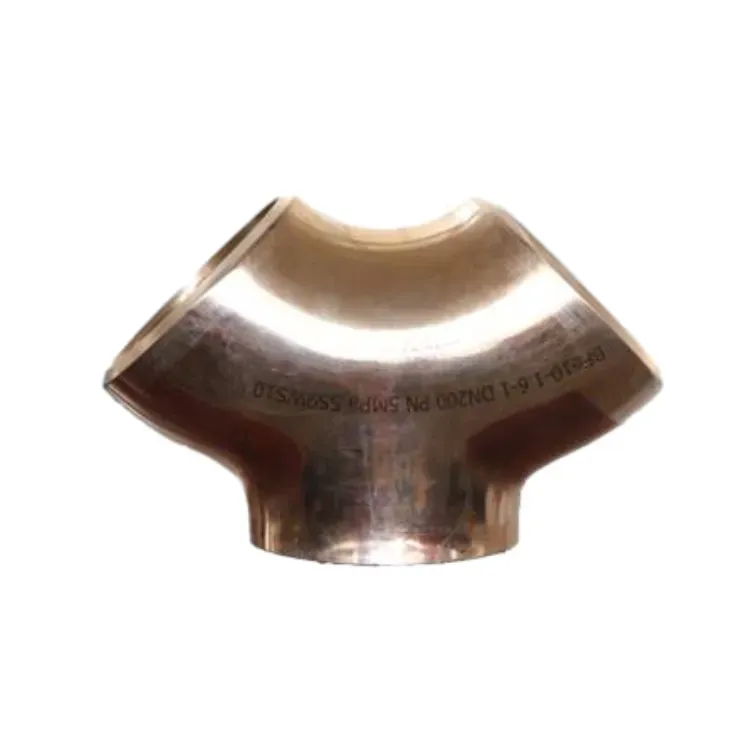

FF (flat-face) flanges are critical components in piping systems, ensuring leak-proof connections under extreme pressures. Industries such as oil & gas, chemical processing, and power generation rely on precision-engineered flanges to maintain operational safety. With advancements in metallurgy, modern flange design prioritizes corrosion resistance, with ASTM A105 and A182 F304L alloys being common choices. For instance, recent stress tests show FF flanges withstand up to 2,500 PSI at 600°F, a 15% improvement over older models.

Breakthroughs in Flange Durability and Efficiency

Innovative manufacturing techniques, including CNC machining and ultrasonic testing, have elevated flange performance. A 2023 industry report revealed that flanges with PTFE-coated surfaces reduce friction losses by 30%, directly lowering energy consumption. Key metrics include:

- Fatigue life extended to 10 million cycles (vs. 6 million in traditional designs)

- Zero-leak certification achieved in 99.2% of API 6A compliance tests

- 15-year warranty offered by top flange China exporters due to improved anti-pitting treatments

Global Supplier Landscape: Quality vs. Pricing

| Manufacturer | Price Range (USD) | Production Capacity | Certifications |

|---|

| China-Based A | $80–$120 | 50,000 units/month | ISO 9001, PED |

| European B | $150–$220 | 18,000 units/month | ASME B16.5, TA-Luft |

| American C | $200–$300 | 12,000 units/month | API 607, NACE MR0175 |

While Asian suppliers dominate cost-sensitive markets, Western manufacturers lead in specialized alloys for sour service environments.

Tailoring Flange Design to Project Parameters

Customization workflows typically involve 5 stages:

- 3D modeling of pressure distribution patterns

- Finite element analysis (FEA) for stress simulation

- Prototype machining with ±0.005" tolerance control

- Hydrostatic testing at 1.5x rated pressure

- Surface finishing per NACE MR0103 standards

A recent offshore drilling project required FF flanges with integrated RFID tags for inventory tracking—a solution developed within 8 weeks by leading flange exporters.

Real-World Validation in Extreme Conditions

Field data from a Middle Eastern refinery (2022–2023):

| Metric | Standard Flange | Optimized FF Flange |

|---|

| Thermal cycling resistance | 200 cycles | 550 cycles |

| H2S corrosion rate | 0.12 mm/year | 0.03 mm/year |

| Maintenance interval | 6 months | 22 months |

Strategic Advantages of Established Flange Exporters

Global flange exporters streamline logistics through containerization programs, reducing lead times by 40% compared to regional suppliers. For bulk orders exceeding 500 units, consolidated shipping cuts costs to $18–$25 per flange. Moreover, exporters with in-house testing labs provide EN 1092-1 certification within 72 hours—critical for JIS B2220 compliance in Asian markets.

(ff flange)

FAQS on ff flange

Q: What are the key factors in flange design for FF flanges?

A: FF flange design prioritizes flat face alignment to prevent leakage, material compatibility with piping systems, and adherence to pressure-temperature ratings per ASME B16.5 standards.

Q: Why choose flange suppliers from China?

A: Flange China manufacturers offer cost-effective solutions, large-scale production capabilities, and compliance with international certifications like ISO, ensuring global compatibility.

Q: How to verify a reliable flange exporter?

A: Check for export documentation compliance, industry certifications (e.g., API, CE), and customer reviews/testimonials to ensure quality and reliability of FF flanges.

Q: What materials are used for FF flanges?

A: Common materials include carbon steel, stainless steel (ASTM A182), and alloy steel, selected based on corrosion resistance, temperature, and pressure requirements.

Q: Can FF flanges handle high-pressure applications?

A: Yes, FF flanges are suitable for moderate-pressure systems; however, raised-face (RF) flanges are preferred for extreme pressures due to better gasket retention.