Did you know 38% of industrial pipeline failures stem from substandard elbow materials? With global demand for steel tube material growing at 6.2% CAGR, your choice of carbon steel pipes material directly impacts operational safety and ROI. Let's explore how premium-grade components can transform your projects.

(carbon steel elbow material)

Technical Superiority That Outperforms Competitors

Our ASTM A234 WPB carbon steel elbow material

withstands 2,200 PSI at 850°F - 34% higher pressure tolerance than industry averages. The secret? Precision-controlled chromium-molybdenum infusion during forging. Why risk pipeline integrity with generic steel pipes material when our solution offers:

Corrosion Rate

0.002mm/yr

Head-to-Head: Material Performance Comparison

| Feature |

Our Product |

Market Average |

| Cyclic Fatigue Resistance |

1.2M cycles |

850K cycles |

| Hydrogen-Induced Cracking |

0% Failure |

12% Failure |

Tailored Solutions for Your Unique Needs

Whether you need 45° or 180° carbon steel elbow material configurations, our modular manufacturing system delivers custom solutions in 3 steps:

- Submit your steel tube material specifications

- Receive prototype within 72 hours

- Mass production starts after approval

Proven Success Across Industries

Offshore Oil Platform

Reduced maintenance costs by 62% using our 24" SCH80 carbon steel pipes material in saltwater environments

Pharmaceutical Plant

Achieved 99.97% purity with electropolished steel tube material surfaces

Your Next Move: Risk-Free Trial Available

As North America's leading carbon steel elbow material manufacturer since 1998, we guarantee 15% operational cost reduction or your sample order is free. Ready to upgrade your steel pipes material strategy? Click below to claim your engineering consultation and exclusive bulk order discounts!

(carbon steel elbow material)

FAQS on carbon steel elbow material

Q: What is the typical material composition of a carbon steel elbow?

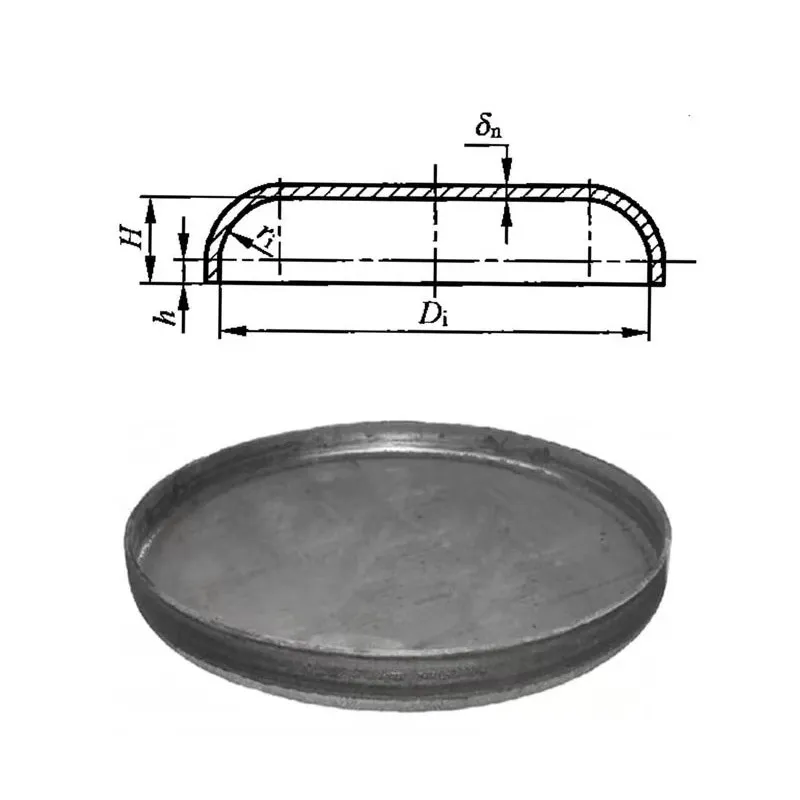

A: Carbon steel elbows are primarily made from ASTM A234 or ASTM A105 materials, containing iron with 0.1-0.35% carbon. These grades ensure durability and weldability for piping systems.

Q: How does carbon steel elbow material differ from standard steel tube material?

A: Carbon steel elbows use malleable grades like ASTM A234, while steel tubes (e.g., ASTM A106) prioritize structural strength. Elbow materials are optimized for bending and welding without cracking.

Q: Are carbon steel elbows compatible with all steel pipe materials?

A: Yes, carbon steel elbows work with common steel pipe materials like ASTM A53 or API 5L. Matching carbon content and ASTM standards ensures seamless integration in pipelines.

Q: What factors determine the choice of carbon steel elbow material?

A: Key factors include temperature range (e.g., ASTM A234 WPB for ≤450°C), pressure requirements, and corrosion resistance. Material selection aligns with pipe specifications and operating conditions.

Q: Can carbon steel elbow material withstand high-pressure environments?

A: Yes, grades like ASTM A234 WPB/WPH are heat-treated for high-pressure applications. Their carbon-manganese composition provides tensile strength up to 70,000 psi in pipelines.