Iron pipe fittings are essential components in plumbing, construction, and industrial applications. These fittings ensure secure connections, directional changes, and efficient flow control in piping systems. This article explores the types, applications, manufacturing processes, and advantages of iron pipe fittings, focusing on common variants such as elbow pipe steel, galvanised steel elbow, and 2 stainless steel tee. Additionally, it discusses specialized fittings like brushed stainless steel newel post caps and butt weld pipe cap, highlighting their roles in various industries.

Types of Iron Pipe Fittings

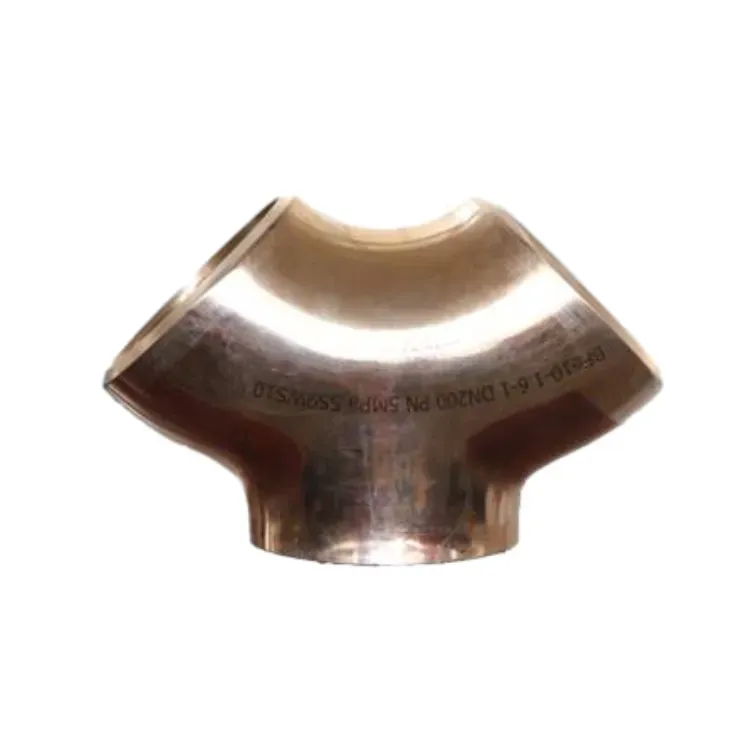

The variety of iron pipe fittings available meets diverse requirements in piping systems. Elbow pipe steel fittings are among the most commonly used, designed to change the direction of flow at standard angles. These fittings are particularly useful in tight spaces where pipes need to navigate around obstacles. The elbow steel butt welding type provides superior strength for high-pressure applications, making them ideal for industrial settings where leak-proof joints are critical.

Another important category includes tee fittings such as the 2 stainless steel tee and 6 stainless steel tee. These components allow for the division or combination of fluid flows in piping networks. The galvanised steel T-section offers similar functionality with added corrosion resistance, making it suitable for outdoor or moisture-prone environments. Each of these tee fittings comes in various sizes to accommodate different pipe diameters and flow requirements.

For architectural and decorative applications, specialized fittings like brushed stainless steel newel post caps and brushed steel newel post caps serve dual purposes. While providing structural support for railings and staircases, they also enhance aesthetic appeal with their polished finishes. The butt weld pipe cap, though simpler in design, plays a vital role in sealing pipe ends securely, preventing contamination and ensuring system integrity.

Manufacturing Processes of Iron Pipe Fittings

The production of high-quality iron pipe fittings begins with careful material selection. Carbon steel and stainless steel are the most commonly used metals, chosen for their strength and durability. For fittings requiring corrosion resistance, such as galvanised steel elbows and galvanised steel T-sections, the base material undergoes additional treatment processes. The selection process ensures each fitting meets the specific demands of its intended application.

Forming and shaping processes vary depending on the type of fitting. Elbow pipe steel and elbow steel butt welding fittings are typically created through hot forming or cold bending techniques. These methods allow for precise angle formation while maintaining structural integrity. For tee fittings like the 2 stainlesssteel tee and 6 stainless steel tee, machining processes ensure accurate dimensions and smooth interior surfaces to minimize flow resistance. Advanced welding techniques are employed to create seamless joints in butt-welded varieties.

Surface treatment represents the final stage in manufacturing. Galvanization provides a protective zinc coating for galvanised steel elbows and related fittings, significantly extending their service life. For decorative elements such as brushed stainless steel newel post caps, specialized finishing techniques create the desired aesthetic effect while maintaining functionality. Quality control measures, including pressure testing and dimensional verification, ensure each fitting meets industry standards before reaching the market.

Applications of Iron Pipe Fittings

In residential and commercial plumbing systems, iron pipe fittings form the backbone of efficient water distribution. The elbow pipe steel fittings enable pipes to navigate building structures effectively, while galvanised steel elbow components prove invaluable in outdoor plumbing due to their rust-resistant properties. These fittings ensure long-term reliability in environments where moisture and corrosion would degrade lesser materials.

Industrial applications demand even more robust solutions. High-pressure systems in chemical plants and refineries rely on elbow steel butt welding fittings for their superior strength and leak resistance. The 2 stainless tee and 6 stainless steel tees fittings manage complex flow patterns in processing equipment, allowing for precise control of liquids and gases. The butt weld pipe cap serves as a critical safety component in these settings, providing secure endpoints for pipelines carrying hazardous materials.

Beyond functional uses, iron pipe fittings contribute to architectural design. The galvanised steel T-section provides structural support in building frameworks, combining strength with corrosion resistance. Decorative elements like brushed stainless steel newel post caps and brushed steel newel post caps enhance the visual appeal of staircases and railings while offering durable protection. These diverse applications demonstrate the versatility of iron pipe fittings across multiple industries.

Iron pipe fittings play a critical role in ensuring the durability, efficiency, and safety of piping systems. From elbow pipe steel to brushed steel newel post cap, each fitting serves a distinct purpose across plumbing, construction, and industrial applications. Their versatility and reliability make them fundamental components in modern infrastructure.