Flanges are crucial components in plumbing and construction systems, providing secure connections and ensuring the integrity of pipelines. Different types of flanges serve specific purposes, and understanding their characteristics and applications is key to successful installation and maintenance. This exploration focuses on various flanges, including oversized shower arm flange, pancake flange, pe flange, pex wall flange, and pipe and flange, highlighting their unique features and uses.

The Utility of Oversized Shower Arm Flanges

In the realm of bathroom fixtures, the oversized shower arm flange plays a vital role in both functionality and aesthetics. Unlike standard flanges, an oversized version offers greater coverage, effectively hiding any imperfections or gaps around the area where the shower arm meets the wall. This is especially important during installation, as it provides a more finished look. For instance, when renovating an older bathroom, an oversized shower arm flange can cover up any damage or discoloration on the wall surface left by the previous shower fixture. It not only enhances the visual appeal but also helps in preventing water from seeping behind the wall, reducing the risk of mold and mildew growth.

Pancake Flanges: Compact and Versatile

Pancake flanges are known for their compact design, which makes them highly versatile in a range of applications. Their flat, thin profile allows for installation in tight spaces where traditional flanges might not fit. In residential plumbing, pancake flanges are commonly used in situations where pipes need to be connected in confined areas, such as under sinks or in narrow utility closets. Their ease of installation, often requiring minimal space for maneuvering tools, makes them a popular choice among plumbers. Additionally, their simple structure enables quick and efficient connections, reducing installation time and labor costs.

PE Flanges: Durable and Corrosion - Resistant

PE flanges, or polyethylene flanges, are prized for their durability and resistance to corrosion. Made from high - quality polyethylene material, these flanges are ideal for use in plumbing systems that carry water or other liquids. In outdoor plumbing setups, where exposure to the elements can cause metal flanges to rust and deteriorate over time, PE flanges maintain their integrity. They are also suitable for use in chemical processing plants or industrial settings where aggressive substances might be present in the pipelines. The chemical resistance of PE flanges ensures that they can withstand harsh conditions without compromising the safety and functionality of the piping system.

PEX Wall Flanges: Perfect for PEX Plumbing Systems

For plumbing systems that utilize cross - linked polyethylene (PEX) pipes, the pex wall flange is an essential component. These flanges are specifically designed to provide a secure connection between PEX pipes and walls, ensuring a watertight seal. When installing PEX pipes in walls for water supply lines, the pex wall flange acts as a protective barrier, preventing water from leaking into the wall cavity. This is crucial for maintaining the structural integrity of the building and avoiding water - related damage. Moreover, pex wall flanges are often easy to install, with features that allow for quick and hassle - free attachment to PEX pipes, making them a preferred choice for both professional plumbers and DIY enthusiasts working on PEX plumbing projects.

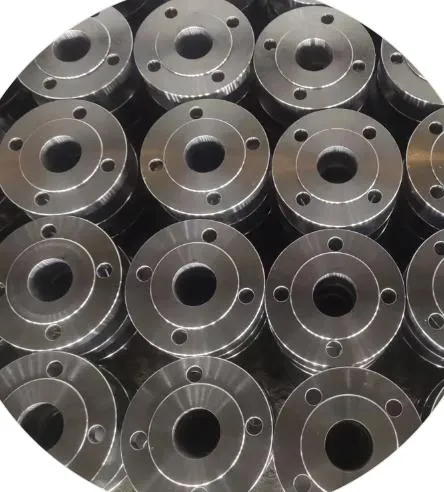

The Basics of Pipe and Flange Connections

The concept of pipe and flange connections is fundamental in plumbing and construction. Flanges are attached to the ends of pipes, and by bolting or welding the flanges together, a secure joint is created. This method of connection allows for easy disassembly and maintenance of the pipeline system. For example, in large - scale industrial piping networks, pipe and flange connections enable workers to isolate sections of the pipeline for repair or replacement without having to disrupt the entire system. Different types of flanges, such as those mentioned above, can be used depending on the specific requirements of the pipe material, fluid being transported, and operating conditions, ensuring a reliable and efficient piping infrastructure.

FAQs about Flanges

How to Choose the Right Flange for a Specific Application?

Selecting the appropriate flange depends on several factors. First, consider the type of pipe material, as different flanges are compatible with specific materials like PEX, PE, or metal pipes. The application environment also matters; for outdoor or corrosive environments, PE flanges might be a better choice, while for bathroom fixtures, an oversized shower arm flange or pancake flange could be more suitable. Additionally, factors such as the pressure and temperature of the fluid in the pipeline, as well as the required level of sealing, should be taken into account when choosing the right pipe and flange combination.

What Are the Installation Tips for Flanges?

When installing flanges, ensure that the mating surfaces of the flanges and pipes are clean and free of debris. For pex wall flanges, make sure the PEX pipe is properly inserted and secured within the flange. When using pipe and flange connections, tighten the bolts evenly to avoid uneven stress and potential leakage. In the case of pancake flanges, take advantage of their compact size and use appropriate tools to fit them into tight spaces without damaging the surrounding components. Always follow the manufacturer's instructions for installation to ensure a safe and reliable connection.

How to Maintain Flanges to Prolong Their Lifespan?

Regular inspection is key to maintaining flanges. Check for signs of corrosion, leakage, or loose bolts in pipe and flange connections. For PE flanges, clean them periodically to remove any dirt or deposits that could potentially affect their performance. In the case of oversized shower arm flanges, ensure that the seal around the flange is intact to prevent water from seeping through. If any issues are detected, address them promptly, whether it involves replacing a damaged flange or tightening loose connections, to prevent further damage and ensure the continued proper functioning of the plumbing or construction system.