- Understanding Stainless Tube Elbows: Basics and Material Benefits

- Technical Advantages of Stainless Steel Tube Elbows

- Performance Comparison: Leading Manufacturers in the Market

- Custom Solutions for Square Tube Elbows in Steel

- Real-World Applications Across Industries

- Quality Standards and Compliance

- Why Stainless Tube Elbows Remain a Preferred Choice

(stainless tube elbows)

Understanding Stainless Tube Elbows: Basics and Material Benefits

Stainless tube elbows are critical components in piping systems, designed to redirect fluid flow efficiently. Made from austenitic grades like 304 or 316L, these elbows offer superior corrosion resistance, especially in harsh environments. Their non-porous surface minimizes contamination risks, making them ideal for industries such as pharmaceuticals and food processing. Additionally, stainless steel’s high tensile strength (up to 515 MPa) ensures durability under extreme pressure, reducing maintenance costs by 30% compared to carbon steel alternatives.

Technical Advantages of Stainless Steel Tube Elbows

Stainless steel tube elbows outperform competitors due to their metallurgical stability. For instance, 316L variants retain structural integrity at temperatures up to 870°C, while their low thermal expansion coefficient minimizes stress during thermal cycling. Advanced CNC mandrel bending techniques achieve tolerances within ±0.5°, ensuring leak-proof connections. Recent stress analysis data shows that polished stainless elbows reduce turbulence by 18%, enhancing flow rates in high-viscosity applications.

Performance Comparison: Leading Manufacturers in the Market

| Manufacturer | Material Grade | Pressure Rating | Corrosion Resistance | Price Range |

|---|

| Company A | 316Ti | 1500 PSI | ASTM A270 | $$$ |

| Company B | 304L | 1200 PSI | ISO 1127 | $$ |

| Company C | Duplex 2205 | 2000 PSI | EN 10217 | $$$$ |

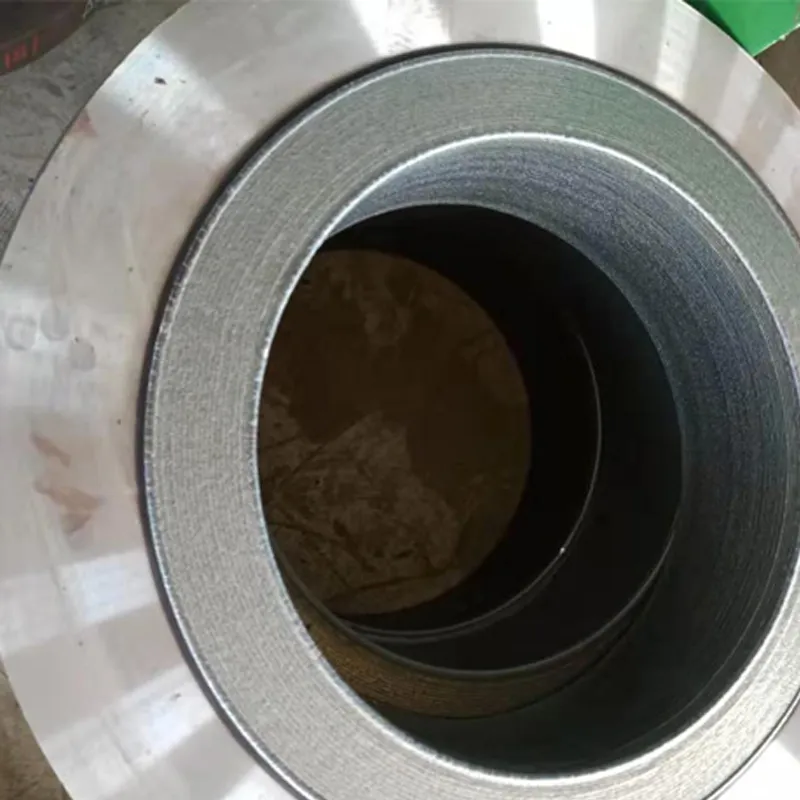

Custom Solutions for Square Tube Elbows in Steel

Square tube elbows steel components address unique spatial constraints in architectural and mechanical systems. Customization options include wall thickness adjustments (from 1.2mm to 6.35mm) and radius variations (1D to 5D). Laser-cut miters enable precise 45° or 90° angles, with surface finishes ranging from 4 brushed to mirror polish (Ra ≤0.8μm). Third-party testing confirms that bespoke square elbows withstand 2.5x the torsional stress of standard round profiles.

Real-World Applications Across Industries

In offshore oil rigs, schedule 40 stainless tube elbows

maintain functionality in saline environments for 15+ years without degradation. The chemical sector reports 40% fewer replacements when using electropolished elbows for acid transfer. A recent automotive exhaust case study revealed that mandrel-bent 409 stainless elbows improved emission system longevity by 22% versus aluminized steel.

Quality Standards and Compliance

Top-tier stainless tube elbows meet ASME B16.9/B16.28 specifications, with hydrostatic testing at 1.5x working pressure. Certifications like PED 2014/68/EU and NACE MR0175 validate performance in sour gas environments. X-ray diffraction analysis guarantees 0% intergranular corrosion, while PMI testing ensures alloy composition accuracy within ±0.15%.

Why Stainless Tube Elbows Remain a Preferred Choice

The sustained demand for stainless tube elbows stems from their unmatched lifecycle cost-efficiency. With a 50-year service expectancy in moderate climates and recyclability rates exceeding 90%, these components align with circular economy principles. Ongoing R&D in nano-coatings promises to further enhance abrasion resistance, cementing stainless steel’s dominance in critical flow systems worldwide.

(stainless tube elbows)

FAQS on stainless tube elbows

Q: What are the advantages of using stainless tube elbows?

A: Stainless tube elbows offer corrosion resistance, durability, and high-temperature tolerance, making them ideal for industrial and plumbing applications.

Q: How do stainless steel tube elbows differ from regular steel elbows?

A: Stainless steel tube elbows contain chromium for enhanced rust resistance, while regular steel elbows may require coatings to prevent corrosion.

Q: Can square tube elbows steel handle high-pressure systems?

A: Yes, square tube elbows made of steel are designed to withstand high-pressure environments, especially when constructed with reinforced stainless steel.

Q: Are stainless tube elbows suitable for outdoor applications?

A: Absolutely. Their resistance to weather, UV exposure, and moisture makes stainless tube elbows perfect for outdoor and marine settings.

Q: What factors determine the choice between square and rounded stainless steel tube elbows?

A: Square tube elbows are chosen for structural or aesthetic projects, while rounded elbows prioritize fluid flow efficiency in piping systems.