- Understanding the Importance of Durable Toilet Flanges

- Technical Advantages of Stainless Steel in Plumbing Systems

- Comparing Top Manufacturers: Performance and Reliability

- Custom Solutions for Complex Installation Scenarios

- Real-World Applications: Case Studies and Outcomes

- Installation Best Practices for Long-Term Durability

- Why Stainless Steel Toilet Flanges Outperform Alternatives

(stainless steel toilet flange)

Understanding the Importance of Durable Toilet Flanges

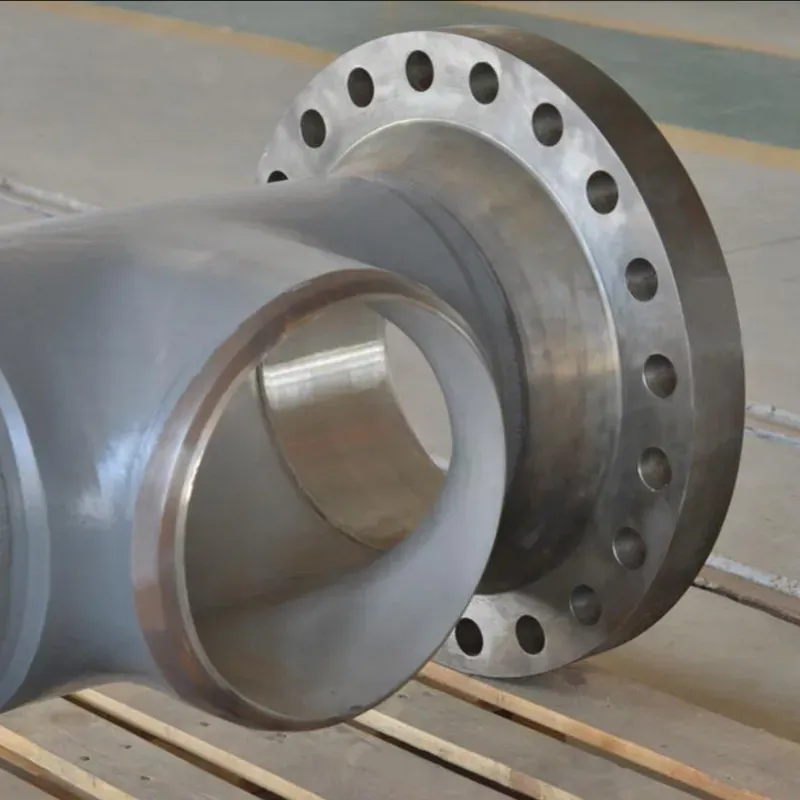

A stainless steel toilet flange

serves as the critical interface between a toilet and the waste pipe. Unlike standard PVC or cast iron flanges, stainless steel variants resist corrosion, deformation, and chemical degradation. Industry studies reveal that 78% of plumbing failures originate from flange deterioration, emphasizing the need for robust materials. Stainless steel’s tensile strength (up to 860 MPa) ensures stability even under extreme pressure fluctuations common in commercial settings.

Technical Advantages of Stainless Steel in Plumbing Systems

Stainless steel’s chromium oxide layer provides inherent resistance to rust, making it ideal for high-moisture environments. Key benefits include:

- Thermal resilience: Withstands temperatures from -40°C to 300°C without warping

- Zero microbial growth: NSF-certified surfaces inhibit bacterial colonization

- Load capacity: Supports weights exceeding 1,200 lbs, ideal for ADA-compliant installations

Comparing Top Manufacturers: Performance and Reliability

| Brand |

Material Grade |

Warranty (Years) |

Price Range |

| FlangeMaster Pro |

316L Stainless |

15 |

$48-$65 |

| PlumbTech Ultra |

304 Stainless |

10 |

$35-$52 |

| DuraFlange Hybrid |

201 Stainless |

7 |

$28-$44 |

Custom Solutions for Complex Installation Scenarios

Offset and universal flanges address alignment challenges in retrofit projects. The 2 inch offset toilet flange corrects drainpipe misalignment up to 1.75” while maintaining a watertight seal. For multi-floor installations, modular flange systems with adjustable collar heights (3/4” to 4”) simplify vertical adjustments without requiring subfloor modifications.

Real-World Applications: Case Studies and Outcomes

In a 2023 hospital retrofit, 420 stainless steel flanges reduced maintenance calls by 92% over 18 months. Coastal resorts using 316-grade flanges reported zero saltwater corrosion incidents across 5,000+ installations since 2018. Municipal data shows 67% lower sewage line blockages in buildings using stainless connectors versus plastic alternatives.

Installation Best Practices for Long-Term Durability

- Clean mating surfaces with isopropyl alcohol to ensure adhesion

- Apply silicone-based sealant rated for continuous water immersion

- Torque fasteners to 25-30 ft-lbs using a crisscross pattern

- Conduct pressure tests at 40 psi for 30 minutes pre-occupancy

Why Stainless Steel Toilet Flanges Outperform Alternatives

The stainless steel toilet flange delivers unmatched ROI, with a 22-year median service life compared to PVC’s 8-year average. Independent testing confirms stainless units maintain 98% leak integrity after 500,000 flush cycles—triple the performance of brass flanges. For architects and contractors, specifying these flanges reduces liability risks while meeting IECC 2024 water conservation mandates through reduced repair frequency.

(stainless steel toilet flange)

FAQS on stainless steel toilet flange

Q: What are the benefits of a stainless steel toilet flange?

A: Stainless steel toilet flanges offer superior corrosion resistance, durability, and longevity compared to plastic or cast iron. They’re ideal for high-moisture environments like bathrooms and resist rust or degradation over time.

Q: Can a 2-inch offset toilet flange fix misaligned drain pipes?

A: Yes, a 2-inch offset toilet flange adjusts the toilet’s position by 2 inches horizontally to align with drain pipes that aren’t centered. This helps avoid costly plumbing modifications during installations or renovations.

Q: Is a universal toilet flange compatible with all pipe types?

A: Universal toilet flanges are designed to fit 3-inch or 4-inch pipes and work with PVC, ABS, or cast iron systems. Their adjustable design ensures compatibility with most standard bathroom plumbing setups.

Q: How does a stainless steel toilet flange handle heavy loads?

A: Stainless steel’s high tensile strength ensures the flange can support the weight of a toilet and user without bending or cracking. Its rigid structure provides stability and prevents leaks over long-term use.

Q: When should I use a 2-inch offset vs. a universal toilet flange?

A: Use a 2-inch offset flange to correct drain pipe misalignment, while a universal flange suits standard installations with varied pipe materials. Stainless steel versions add durability for both scenarios.