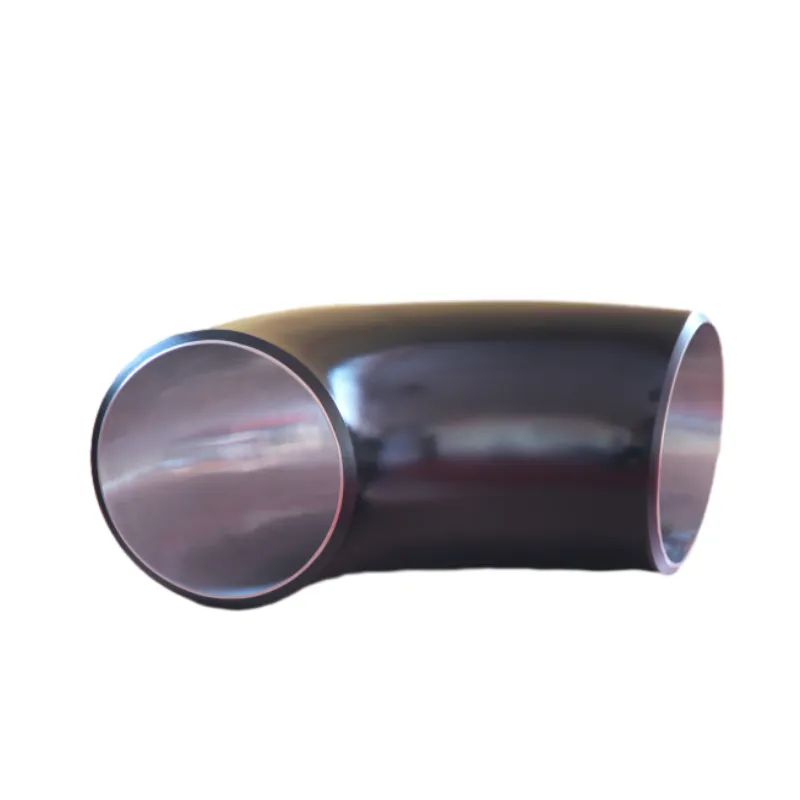

High-precision steel elbow application in industrial pipeline system

The demand for steel elbow solutions—including steel elbow, stainless steel elbow, stainless steel 180 degree elbows, and galvanized steel elbow—is surging across industries due to stricter codes, sustainability drives, and enhanced safety standards. Backed by authoritative certifications (ISO 9001, ANSI B16.9, FDA-compliant coatings), these components are fundamental to modern petrochemical, metallurgical, HVAC, water, and gas transmission networks.

$7.2 Billion

2023 Global Pipe Fittings Elbow Market

5.8% CAGR

Forecast 2023–2028 (Elbow Segment)

20+ Years

Field Service Lifetime (Avg. for stainless steel elbow)

Key Parameters of Steel Elbow Types

| Type |

Standard |

Common Material |

Bend Angle |

OD Range (mm) |

Pressure Class |

Corrosion Resistance |

Lifespan |

| Carbon Steel Elbow |

ANSI B16.9 |

ASTM A234 WPB |

45°, 90°, 180° |

15 – 1500 |

PN10–PN100 |

Medium |

10–15 yrs |

| Stainless Steel Elbow |

DIN 2605 |

ASTM A403 WP304/316 |

45°, 90°, 180° |

15 – 1200 |

PN10–PN100 |

Excellent |

20–30 yrs |

| Stainless Steel 180 Degree Elbows |

ISO 3419 |

316L/304L |

180° |

20 – 800 |

PN10–PN64 |

Excellent |

25–35 yrs |

| Galvanized Steel Elbow |

EN 10242 |

ASTM A53, A105 |

90°, 45° |

15 – 600 |

PN10–PN40 |

Good |

8–15 yrs |

Steel Elbow Manufacturing Process Flow

Raw Material Selection

(Certified steel billets & pipe: ASTM/EN)

→

Forming (Hot/Cold Bending or Mandrel Forging)

→

CNC Machining & Trimming

(Precision tolerance matching)

→

Heat Treatment & Pickling

(Stress relieving, corrosion resistance)

→

Non-Destructive Testing (NDT)

(Ultrasonic/X-ray; ISO 9712, ANSI/ASME B31.3)

→

Final Inspection & Packaging

(Marking, export seaworthy packs)

Superior corrosion resistance: stainless steel elbow installed in food-grade pipeline

Material Selection & Technical Specifications

Steel elbow materials are tailored for specific environments:

- Carbon Steel (ASTM A234 WPB): Economic, high toughness, suited for oil & gas or city pipeline networks (operating temp. −20–425°C).

- Stainless Steel (304, 304L, 316, 316L): Exceptional anti-corrosion, ideal for pharmaceutical, food, and chemical sectors (ISO 1127 compliance; 180°C up to 540°C).

- Galvanized Steel: Hot-dipped zinc-coated, good resistance for outdoor or water supply under moderate corrosive risk.

Typical wall thickness: SCH10S~SCH160 (

Schedule refers to wall thickness standard as per ASME B36.10/36.19).

Elbow diameters range from DN15 (1/2") to DN1500 (60") with custom angles (22.5°, 45°, 60°, 90°, 180°).

Hot-dip galvanized protection: galvanized steel elbow in urban drainage

Performance Comparison & Technical Data Visualization

● Carbon Steel Elbow

● Stainless Steel Elbow

● Galvanized Steel Elbow

Figure 1: Corrosion resistance index comparison by material type (lab salt spray test, 48h ASTM B117 method, score 0~10 highest).

Figure 2: Expected field service life under moderate corrosive conditions.

Figure 3: Global steel elbow market share by material (2023).

Process detail: Mandrel forming for steel elbow with precision controls

Manufacturing Process Explanation

- Mandrel Forming: Enables uniform wall thickness, especially for large-diameter steel elbow.

- Hot Bending: Yields high-strength elbows, often for high-pressure use; typical temp 800–1100°C.

- CNC Machining: Delivers precise angle/length control and smooth internal bores, reducing flow turbulence.

- Surface Treatment: Pickling, passivation (stainless steel elbow), or galvanizing for tailored protection.

- NDT Inspection: Ultrasonic, radiographic, or dye-penetrant testing to detect internal/external flaws—mandatory per ISO 9001 and PED regulations.

Every steel elbow is tracked by heat number and third-party inspection certificate.

Custom-formed stainless steel 180 degree elbows for chemical reactor piping

Industry Application Scenarios & Advantages

- Petrochemical: High-pressure crude refining and transportation lines demand superior stainless steel elbow with tested lifecycle and compliance to ASME B31.3/ISO 14692.

- Power Generation: Superheated steam carries up to 520°C; steel elbow with thermal fatigue-resistant microstructure is chosen (ref. EN10216-2).

- Municipal Water Supply: galvanized steel elbow are vital for longevity under intermittent service, especially for potable water. Recent studies show up to 40% reduction in corrosion failures over the past 5 years (source: [Pipe Research Council](https://www.prc.org/)).

- Pharmaceutical & Food: stainless steel 180 degree elbows (sanitary grade, electropolished) minimize dead zones and support Clean-in-Place (CIP) operations per FDA/3-A standards.

- Mining/Slurry: High-wear resistant carbon steel elbows with ceramic lining (optional) are utilized for abrasive mineral transport.

Heavy-duty steel elbow deployed in mineral slurry pipes

Case Study: Upgrading Petrochemical Piping Network in Middle East

In 2022, LION supplied 15,000+

stainless steel elbow (sizes DN200–DN800) to

Petro-MEGA, a major oil & gas operator. The elbows, produced per ISO 9001 and PED standard, were deployed in complex, high-H2S pipelines. FEED phase testing indicated a 37% drop in joint failure rates compared to legacy carbon steel elbows, as well as energy savings of 6% due to reduced friction (

O&G Pipeline Journal, 2023).

Client Feedback: "LION's

steel elbow exceeded our quality and compliance expectations, reducing maintenance frequency and leak risks.”

Comparative Analysis: Suppliers & Custom Solutions

When selecting a steel elbow supplier, consider these benchmarks:

- Certifications: ISO 9001, PED 2014/68/EU, ANSI/ASME, API.

- Material Origin: Traceability from the mill to final shipment.

- Non-Destructive Testing: Full NDT, PMI testing.

- Custom Engineering: CAD/3D drawings & FEA simulation for project-specific requirements.

- Warranty & After-sales: Minimum 12–36 months product guarantee, rapid technical support.

LION offers full customization: from radius, wall thickness, to flanged/Bevel ends, logo marking, and custom paint/lining. Pre-shipment video inspection is available.

Quality assurance: Spectro & ultrasonic steel elbow test report

Product Comparison Table: Leading Steel Elbow Suppliers (2024)

| Supplier |

Country |

Certs |

Elbow Size Range |

Inspection |

Custom Options |

Avg. Lead Time (days) |

| LION |

China |

ISO, ANSI, PED |

DN15–DN1500 |

100% NDT |

Color, Lining, Ends |

15–30 |

| Viega |

Germany |

ISO, DIN |

DN10–DN600 |

Sampled NDT |

Limited |

25–35 |

| Victaulic |

USA |

ISO, ANSI, UL |

DN50–DN1200 |

Sampled |

Color only |

18–40 |

| Benkan |

Japan |

JIS, ISO |

DN10–DN600 |

Randomly sampled |

N/A |

30–50 |

Typical Delivery Terms, Warranty, and Customer Support

- Lead Time: Standard steel elbow (DN50–DN1200, SCH40/80) ships in 18–30 calendar days. Complex custom projects: 30–60 days.

- Warranty: 18–36 months warranty depending on spec and usage, against material or manufacturing defects.

- Post-Sales Support: Installation manuals, 24/7 tech-hotline, virtual FAT/inspection, and on-site audit if required.

- Traceability: Each steel elbow ships with mill test certificate, NDT report, marking traceable to heat batch and inspector's ID.

OEM Custom steel elbow options: size, logo, color, lining

FAQs on Steel Elbow Technical Terms & Usage

1. What does "SCH" mean in a steel elbow specification?

SCH stands for "Schedule", indicating pipe wall thickness as per ASME B36.10/36.19. Example: SCH40 (medium), SCH80 (heavy duty). Thicker schedule = higher pressure rating.

2. What's the difference between "seamless" and "welded" steel elbow?

Seamless elbows are produced from solid billet without welds, offering better pressure/temperature endurance. Welded elbows are made from plate/butt welding, cost-effective for large diameters (above DN600/24”).

3. What is "Pickling & Passivation" for stainless steel elbow?

A cleaning treatment in acid baths removes scale, then passivation builds a chromium-rich oxide layer, drastically boosting corrosion resistance—crucial for food/pharma use.

4. What documents are supplied with each steel elbow shipment?

Every shipment includes mill test certificate (MTC EN10204 3.1/3.2), NDT report, conformity declaration, and, if needed, country-of-origin and third-party inspection results.

5. What is the best installation angle tolerance for elbows?

ISO 3419 and ANSI B16.9 require angle deviation within ±1° and offset within ±1.5mm for diameters up to DN600, ensuring reliable fit-up and minimal flow turbulence.

6. Is it possible to provide elbows with PTFE or rubber lining?

Yes; for extreme chemical or abrasive mediums,

steel elbow with inner PTFE/Ceramic/EPDM (FDA/USP approval) are widely available from LION’s production lines.

7. What surface roughness is typical for sanitary-grade stainless steel elbow?

A Ra < 0.8μm (or even <0.4μm for pharma) is achieved by internal polish or electropolishing per EN 10357, preventing microbe deposition.

Conclusion & Authoritative References

Selecting steel elbow—whether stainless steel elbow, stainless steel 180 degree elbows, or galvanized steel elbow—requires a nuanced grasp of standards, manufacturing excellence, application know-how, and robust after-sales support. Data shows that well-engineered elbows cut system downtime, improve fluid dynamics, and extend asset life.

For proven supplier expertise, technical customization, and industry-backed certifications, LION’s steel elbow range stands out.

On-site steel elbow installation for water conveyance project

Cited References