| Parameter | Standard Value | Remarks |

|---|---|---|

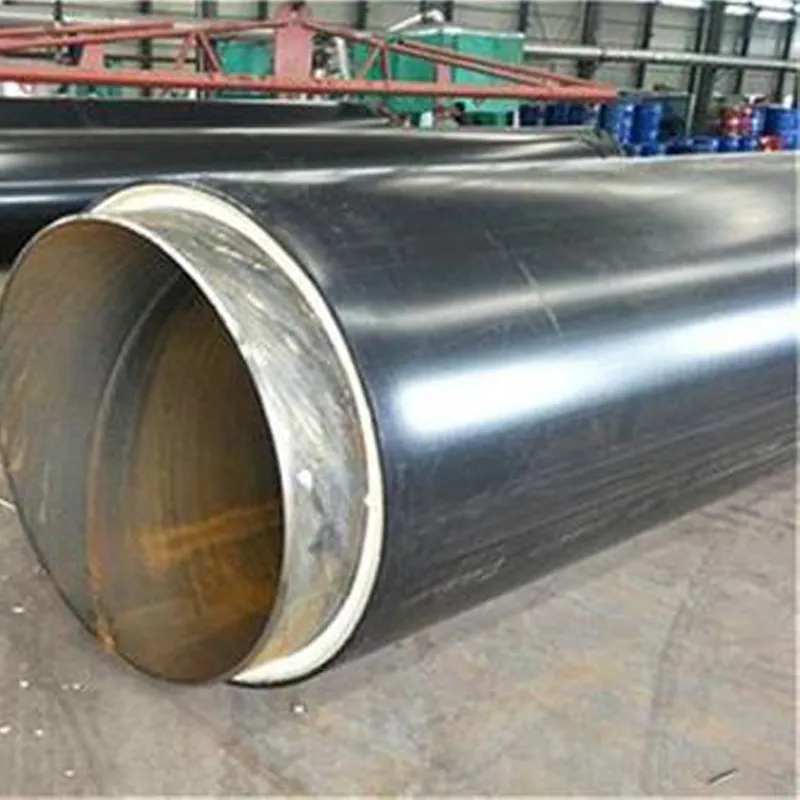

| Pipe Material | Q235B, API 5L (GrB/X42), 304/316L | Customizable for project |

| Pipe OD | 21.3–1220 mm | DN20–DN1200 (EN) |

| Thermal Conductivity (Foam) | λ = 0.024–0.033 W/m·K | PUR PUR foam |

| Insulation Thickness | 30–100 mm | Per design spec |

| Outer Casing | HDPE, FBE Steel, 3LPE | Corrosion & Mechanical |

| Standard | EN253, ISO 9001:2015, API 5L | CE/FDA on request |

| Service Life | 30+ years | Harsh industrial env. |

| Supplier | Pre Insulated Steel Pipe Type | Max Service Temp (°C) | Insulation Type | Outer Casing | Typical Project | Certifications |

|---|---|---|---|---|---|---|

| Lion Pipeline | Carbon steel, SS, twin-pipe | 140 (160 peak) | PUR/PIR | HDPE, 3PE, Steel | China DHC, Chem. Plants | ISO, EN, API, ANSI |

| LOGSTOR | Steel, copper, composite | 120 | PUR | HDPE | EU District Heating | EN, ISO |

| Perma-Pipe | Carbon/Stainless steel | 120 | PUR | HDPE, Steel | Middle East Oil | ISO, ANSI |

| Craley Group | Steel | 110 | PIR | HDPE, Steel | UK Infra | ISO |

| Technical Attribute | Anti Corrosion And Thermal Insulation Products | Industry Average |

|---|---|---|

| Thermal Conductivity (PUR, W/m·K) | 0.024–0.029 | 0.027–0.033 |

| Service Life (Years) | 30–50 | 20–30 |

| Max. Service Temp (°C) | 140 (short-term 160) | 120–130 |

| Corrosion Resistance Test | Pass (ASTM B117, 1000hr+) | Pass (min. 500hr) |

| ISO/EN Certification | Yes (9001, 253) | Partial |

The adoption of pre insulated steel pipe brings undeniable advantages in energy efficiency, reliability, and long-term operation costs—supported by international test data, advanced anti-corrosion pipe coating technology, and customizable solutions. When choosing your supplier, focus on not just price, but on proven performance, compliance, and transparent QA. Lion Pipeline and industry leaders continually set higher benchmarks—empowering sustainable urban and industrial infrastructure worldwide.

Anti Corrosion And Thermal Insulation Products

Where to Buy Stainless Steel Pipes and Tubing for Sale Together

The Future of Smart Flange Technology

Tee Pipe Fitting in Industrial Process Piping

Prefabricated Pipe in Shipbuilding Applications

How Anti Corrosion Pipe Extends Pipeline Lifespan

Cts Pipe Fittings for Potable Water Systems

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.