In the intricate world of industrial piping systems, the integrity and efficiency of fluid transport are paramount. A seemingly simple yet profoundly critical component ensuring these attributes is the stainless steel cap. These essential fittings are designed to close the end of a pipe, providing a robust seal against leaks, protecting internal components from contaminants, and facilitating maintenance or future system expansion. Their widespread adoption across diverse sectors, including petrochemicals, pharmaceuticals, food and beverage, and water treatment, underscores their unparalleled reliability and versatility. Manufactured from various grades of stainless steel, such as 304, 316, or specialized duplex alloys, these caps offer exceptional resistance to corrosion, high temperatures, and extreme pressures, making them indispensable in environments where operational continuity and safety cannot be compromised. The choice of a specific stainless steel grade often hinges on the chemical composition of the conveyed medium, the ambient conditions, and the required service life, ensuring optimal performance and compliance with stringent industry standards.

The demand for high-performance industrial components continues to grow, driven by an escalating emphasis on operational safety, environmental protection, and cost-efficiency. In this context, the role of the stainless steel cap becomes even more pronounced. Advancements in material science and manufacturing technologies have led to the development of caps capable of withstanding increasingly aggressive operating conditions, including highly corrosive substances and extreme thermal cycling. Furthermore, the industry is witnessing a trend towards modular design and pre-fabricated piping solutions, where precisely manufactured caps contribute significantly to ease of installation and reduced downtime. Customization, such as the development of specific dimensions, unique thread configurations for a threaded steel cap, or specialized finishes for hygienic applications, is also a key driver, allowing engineers to design highly optimized systems tailored to exact project requirements. This evolution reflects a broader industry movement towards intelligent infrastructure and advanced material utilization to enhance overall system resilience and longevity.

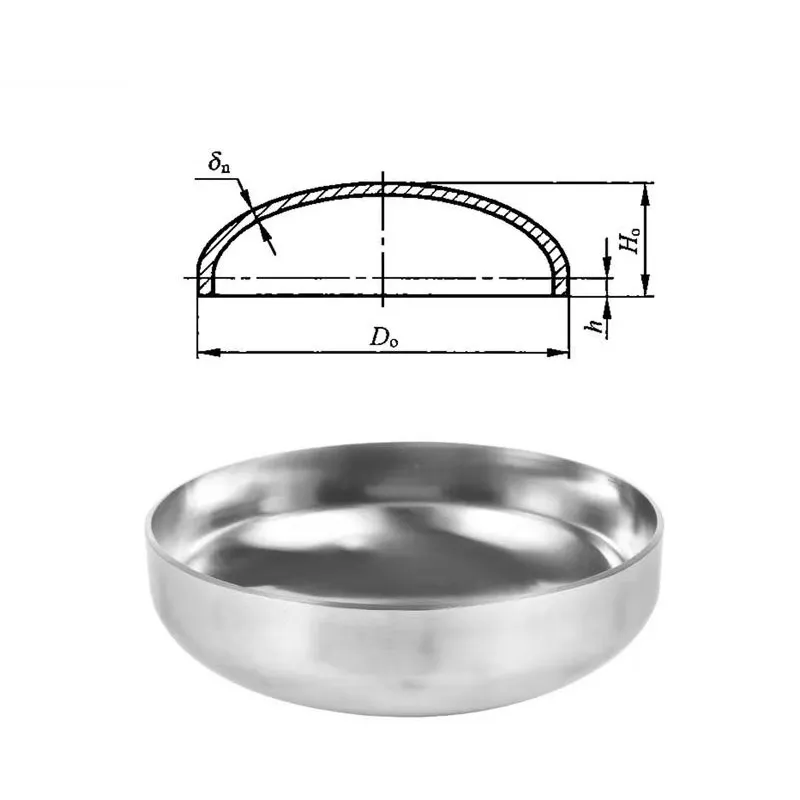

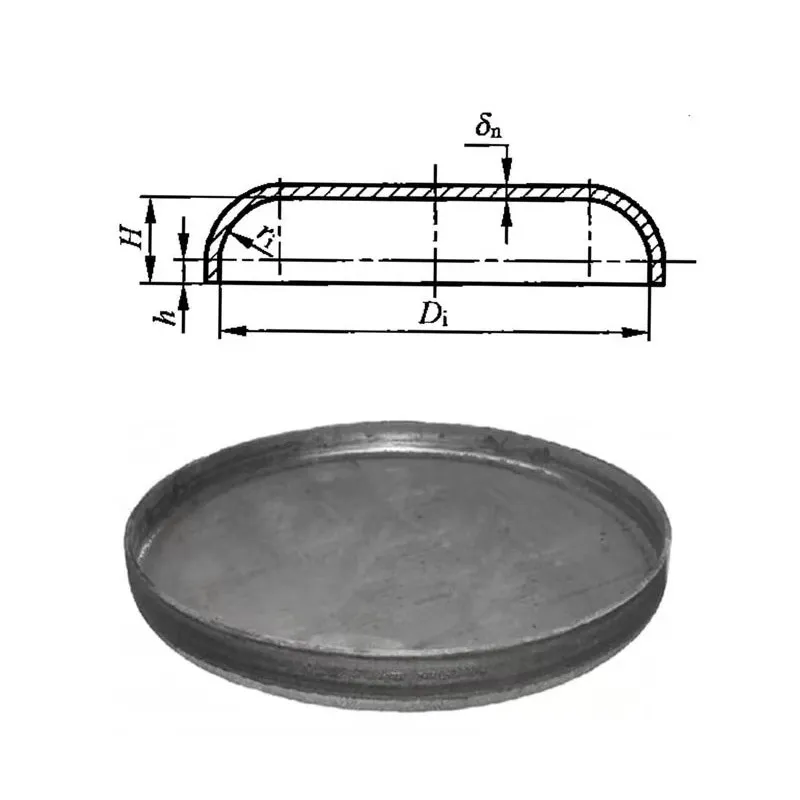

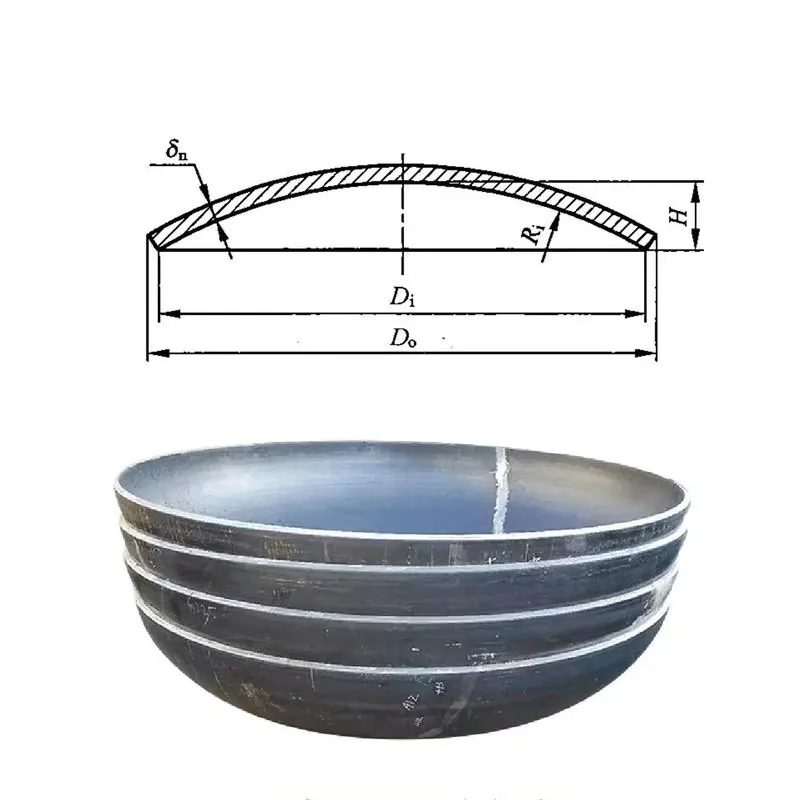

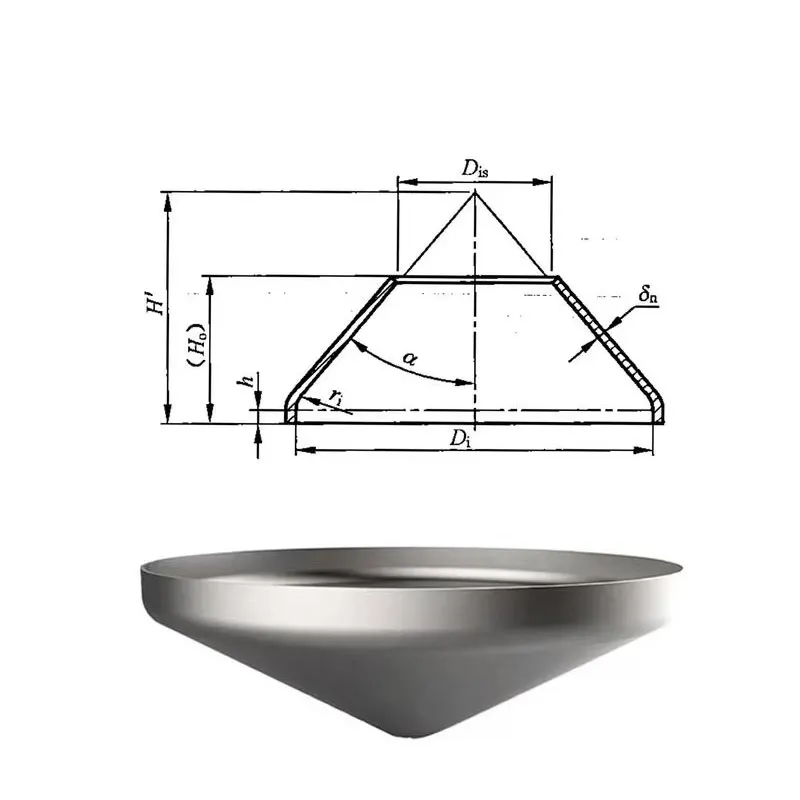

The production of a high-quality stainless steel cap is a meticulous process that combines advanced metallurgical principles with sophisticated manufacturing techniques, ensuring the final product meets the stringent demands of industrial applications. The journey typically begins with the selection of premium-grade stainless steel raw materials, often sourced in the form of seamless pipes or plates, adhering to international standards like ASTM A403 for wrought austenitic stainless steel piping fittings. Depending on the desired cap type and size, various forming processes are employed. For larger diameter caps, hot forming, such as dishing and flanging, might be used, involving heating the material to a high temperature to facilitate shaping without inducing excessive stress. Smaller, more precise caps or those requiring a specific type of end connection, like a butt weld pipe cap, might undergo cold forming techniques or be machined from solid bar stock using Computer Numerical Control (CNC) technology, which guarantees exceptional dimensional accuracy and surface finish.

Following the initial forming, subsequent critical steps include heat treatment, where applicable, to relieve internal stresses and optimize mechanical properties, followed by surface finishing processes such as pickling and passivation to enhance corrosion resistance and aesthetics. Welding, if required for certain designs or sizes, is performed using highly controlled techniques to maintain the integrity of the material. A paramount aspect of the manufacturing process is rigorous quality control and inspection. Every stainless steel cap undergoes a series of stringent tests to comply with globally recognized standards such as ISO 9001 for quality management, ANSI/ASME B16.9 for wrought fittings, and API 5L for line pipe specifications. These inspections often include dimensional checks, material composition analysis (Positive Material Identification - PMI), non-destructive testing (NDT) like ultrasonic or radiographic testing for internal flaws, and hydrostatic pressure tests to verify leak tightness and pressure handling capabilities. This comprehensive approach ensures a service life often extending decades, even in challenging operational environments, contributing significantly to reduced maintenance costs and enhanced operational safety across industries like petrochemicals, metallurgy, and water supply and drainage systems.

Understanding the technical parameters of a stainless steel cap is crucial for proper selection and system design, directly impacting the performance, safety, and longevity of piping infrastructure. Key specifications include the material grade, nominal pipe size (NPS), wall thickness (schedule), pressure rating, and end connection type. For instance, the material grade typically ranges from austenitic stainless steels like SS304 and SS316, known for their excellent corrosion resistance and weldability, to more specialized grades like duplex stainless steels (e.g., 2205, 2507) which offer superior strength and resistance to stress corrosion cracking, particularly in chloride-rich environments. The NPS defines the outer diameter of the pipe the cap fits onto, while the schedule dictates the wall thickness, which in turn determines the cap's ability to withstand internal pressure. Pressure ratings, often expressed in pounds (e.g., Class 150, 300, 600) or as maximum working pressure (MWP) in PSI or Bar, are critical for ensuring compatibility with system operating conditions.

End connection types are another vital parameter. The butt weld pipe cap is designed to be welded directly to the pipe, providing a permanent, leak-proof connection that is ideal for high-pressure and high-temperature applications where maximum flow integrity is required. In contrast, a threaded steel cap features internal or external threads (NPT, BSPT) allowing for easier installation and removal, making it suitable for systems requiring frequent maintenance or modifications, commonly found in instrumentation or smaller utility lines. Furthermore, surface finishes, such as polished surfaces for hygienic applications in the food and pharmaceutical industries, or standard mill finishes for general industrial use, also play a significant role. Below is a comprehensive table outlining typical specifications for various stainless steel caps, designed to provide a quick reference for engineers and procurement specialists. These parameters collectively ensure that each stainless steel cap is precisely engineered to perform reliably under its specific operational demands, contributing to the overall integrity and efficiency of the pipeline system.

| Parameter | Description | Common Values/Standards |

|---|---|---|

| Material Grades | Austenitic, Duplex, Super Duplex Stainless Steel | SS304/304L, SS316/316L, SS321, SS904L, Duplex 2205, Super Duplex 2507 |

| Manufacturing Standards | Dimensions and Tolerances | ASME B16.9, MSS SP-43, DIN, EN |

| Connection Types | Method of connecting to pipe | Butt Weld, Threaded (NPT, BSPT), Socket Weld |

| Size Range | Nominal Pipe Size (NPS) / DN | 1/2" to 72" (DN15 to DN1800) and larger for custom |

| Wall Thickness (Schedule) | Pipe wall thickness compatibility | Sch 10, Sch 20, Sch 40, Sch 80, Sch 160, XS, XXS |

| Pressure Ratings | Maximum allowable operating pressure | Class 150, 300, 600, 900, 1500, 2500 (for welded); various PSI/Bar for threaded |

| Surface Finish | Internal and external surface treatment | Mill finish, Pickled & Passivated, Polished (Grits 180, 240, 320), Bright Annealed |

The versatility of the stainless steel cap makes it an indispensable component across an expansive array of industries, each leveraging its unique properties to enhance system integrity and operational efficiency. In the highly demanding oil and gas sector, particularly within upstream, midstream, and downstream operations, these caps are critical for sealing pipelines transporting crude oil, natural gas, and refined products, often under conditions of high pressure, extreme temperatures, and corrosive media. Similarly, in the chemical and petrochemical industries, stainless steel caps are essential for containing aggressive chemicals, preventing leakage, and safeguarding personnel and the environment. The food and beverage and pharmaceutical industries rely heavily on highly polished stainless steel cap variants to maintain sanitary conditions, preventing bacterial growth and ensuring product purity, which is paramount for consumer safety and regulatory compliance. Their inherent corrosion resistance and ease of cleaning contribute significantly to reducing the risk of contamination and facilitating stringent hygiene protocols.

Beyond these traditional sectors, stainless steel cap fittings are increasingly being utilized in renewable energy projects, such as solar thermal and geothermal power plants, where they must withstand unique thermal cycling and environmental stresses. In water treatment facilities, they ensure the purity of potable water systems and effective management of wastewater, offering long-term reliability against corrosion from waterborne chemicals. A notable application also includes the widespread use of a custom stainless steel chimney cap in residential and commercial heating systems, designed to protect flues from weather elements, prevent animal intrusion, and optimize draft efficiency. Current industry trends indicate a growing emphasis on smart piping systems, incorporating sensors for real-time monitoring of pressure and temperature, where robust and reliably sealed caps are foundational. There's also a rising demand for lightweight yet high-strength caps, driven by a push for energy-efficient transport and installation. The material's recyclability further aligns with global sustainability initiatives, making it a preferred choice for future-proof industrial infrastructure.

The inherent technical advantages of a stainless steel cap make it the material of choice for demanding industrial environments, offering superior performance compared to alternatives like carbon steel or plastics. Foremost among these advantages is its exceptional corrosion resistance. Stainless steel forms a passive chromium oxide layer on its surface, which self-repairs in the presence of oxygen, providing an impenetrable barrier against rust and various corrosive media, including acids, alkalis, and chlorides. Different grades, such as SS304 and especially SS316 with its molybdenum content, offer enhanced resistance to pitting and crevice corrosion, crucial in marine environments or chemical processing plants. This longevity directly translates into significant long-term cost savings by reducing the need for frequent replacements and maintenance, thereby minimizing operational downtime and ensuring continuous productivity.

Beyond corrosion resistance, the high mechanical strength and durability of the stainless steel cap are critical attributes. Stainless steel exhibits excellent tensile strength and yield strength, allowing these caps to withstand high internal pressures and external forces without deforming or failing. This robustness is particularly vital for a butt weld pipe cap in high-pressure steam lines or a threaded steel cap in hydraulic systems, where failure could lead to catastrophic consequences. Furthermore, stainless steel maintains its structural integrity across a wide range of temperatures, from cryogenic conditions to elevated temperatures found in exhaust systems or heat exchangers, without becoming brittle or losing strength. Its non-reactive nature also ensures that it does not contaminate the conveyed fluid, which is indispensable for applications in food, pharmaceutical, and ultra-pure water systems. The combination of these attributes—superior corrosion resistance, high strength, temperature stability, and hygienic properties—positions the stainless steel cap as an optimal and cost-effective solution for ensuring the reliability and safety of industrial piping infrastructure, ultimately leading to enhanced energy efficiency through reduced leakage and optimized flow dynamics.

Selecting the appropriate stainless steel cap manufacturers is as crucial as specifying the right product, directly influencing the quality, reliability, and long-term cost-effectiveness of your industrial projects. A thorough evaluation should go beyond mere price comparisons and delve into aspects such as material sourcing ethics, adherence to international quality standards, manufacturing capabilities, and after-sales support. Reputable manufacturers typically possess certifications like ISO 9001 for quality management, demonstrating a commitment to consistent product quality and process efficiency. Furthermore, look for suppliers with extensive experience in the specific industries you operate within, as this often indicates a deeper understanding of unique challenges and regulatory requirements, such as those governing hygienic fittings in the pharmaceutical sector or high-pressure components in oil and gas. Their ability to provide detailed material test reports (MTRs) and verifiable product traceability is a testament to their transparency and commitment to quality assurance.

Beyond standard offerings, the capacity for developing custom stainless steel chimney cap solutions or bespoke industrial pipe caps is a critical differentiator for leading stainless steel cap manufacturers. This capability allows clients to address unique design challenges, space constraints, or specific performance requirements that off-the-shelf products cannot meet. Customization can involve non-standard sizes, specialized alloys for extreme environments, unique surface finishes for aesthetic or functional purposes, or integrated features like sensor ports or quick-release mechanisms. A manufacturer with robust R&D capabilities, advanced CNC machining, and flexible production lines can turn complex engineering drawings into tangible, high-performance components. Evaluating a manufacturer’s track record, reviewing their portfolio of past projects, and soliciting client testimonials can provide valuable insights into their ability to deliver complex custom solutions on time and within budget, ensuring that your specific operational needs are met with precision and reliability.

The foundation of a reputable supplier relationship in the B2B sector for components like the stainless steel cap is built on unwavering trust and a demonstrated commitment to quality. Leading manufacturers adhere to rigorous quality assurance protocols throughout the entire production lifecycle, from raw material inspection to final product packaging. This commitment is often evidenced by comprehensive certifications such as ISO 9001:2015, American Petroleum Institute (API) standards, and adherence to American Society of Mechanical Engineers (ASME) codes, which dictate strict requirements for design, manufacturing, and testing of pressure components. Our manufacturing processes include 100% Positive Material Identification (PMI) testing to verify alloy composition, ensuring that every stainless steel cap is made from the specified material grade. Furthermore, products undergo comprehensive dimensional checks using precision instruments, along with non-destructive testing (NDT) methods like ultrasonic testing (UT), radiographic testing (RT), and dye penetrant testing (DPT) to detect any internal flaws or surface imperfections that could compromise integrity under operational stress.

Beyond strict manufacturing and testing, a robust framework of customer support and service guarantees underscores a manufacturer’s trustworthiness. This includes transparent communication regarding lead times and delivery schedules, with a typical delivery cycle for standard stainless steel cap orders ranging from 7-14 business days, with expedited options available for urgent requirements. We provide comprehensive warranties that cover manufacturing defects, offering peace of mind and protecting client investments. Our dedicated technical support team is available to assist with product selection, installation guidance, and troubleshooting, ensuring optimal performance and longevity of the installed components. For example, in a recent project for a major chemical processing plant, our team collaborated closely with their engineers to deliver specialized butt weld pipe cap fittings under a tight deadline, navigating complex material specifications and inspection requirements, culminating in a successful and on-schedule system commissioning. This holistic approach, combining product excellence with unparalleled service, cements long-term partnerships and reinforces client confidence in the reliability and performance of every stainless steel cap supplied.

A butt weld pipe cap is designed for permanent installation, requiring welding to the pipe end, which creates a strong, leak-proof, and seamless connection ideal for high-pressure, high-temperature, and corrosive environments such as those found in oil & gas or chemical processing. This connection type minimizes potential leakage points and offers superior structural integrity. In contrast, a threaded steel cap features internal or external threads (e.g., NPT, BSPT) that allow it to be screwed onto a corresponding threaded pipe end. This design facilitates easier installation, removal, and maintenance, making it suitable for applications where flexibility and frequent access are required, typically in lower pressure systems or instrumentation lines. The choice depends on the specific application's pressure rating, temperature range, and maintenance requirements.

Selecting the appropriate stainless steel grade for a stainless steel cap is critical and depends on several factors, primarily the operating environment and the conveyed medium. For general corrosive resistance and good weldability, SS304/304L is a common choice, suitable for many food and beverage, architectural, and general industrial applications. For more aggressive environments, particularly those involving chlorides (e.g., seawater, brine, certain chemicals), SS316/316L (with molybdenum content) offers superior resistance to pitting and crevice corrosion. For extremely harsh conditions, such as highly corrosive media or high-stress environments, duplex stainless steels (e.g., 2205, 2507) or even super austenitic grades like 904L provide enhanced strength and corrosion resistance. Consulting with a materials engineer or the stainless steel cap manufacturers directly, providing details on temperature, pressure, and chemical composition of the medium, is highly recommended to ensure optimal material selection.

Absolutely. Customization is a key offering from specialized stainless steel cap manufacturers. A custom stainless steel chimney cap can be designed to meet specific architectural aesthetics, unusual flue dimensions, or enhanced functional requirements beyond standard offerings. This can involve tailored dimensions, unique aesthetic designs (e.g., specific finishes, decorative elements), integration of mesh screens for pest control, or specialized ventilation features to optimize draft. Manufacturers with advanced fabrication capabilities, including precise laser cutting and bending, can produce custom chimney caps that not only perform exceptionally but also blend seamlessly with or enhance the building's design. Providing detailed blueprints or collaborating with the manufacturer’s design team ensures the custom cap perfectly fits both the technical and aesthetic criteria of your project.

Overlay Welding Clad Steel Pipe

Anti Corrosion And Thermal Insulation Products

Where to Buy Stainless Steel Pipes and Tubing for Sale Together

The Future of Smart Flange Technology

Tee Pipe Fitting in Industrial Process Piping

Prefabricated Pipe in Shipbuilding Applications

How Anti Corrosion Pipe Extends Pipeline Lifespan

Cts Pipe Fittings for Potable Water Systems

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.