The global market for steel pipes for sale is evolving rapidly, driven by advances in manufacturing, stricter industry standards, and the increasing demand for corrosion-resistant, high-performance pipelines. On this page, we explore the current industry landscape, analyze core technical parameters, present direct steel pipes for sale product links, and offer insights into welded pipe technologies, composite manufacturers, and case-proven applications.

Steel pipes for sale – state-of-the-art production line

Steel pipes for sale – state-of-the-art production line

1. Industry Overview and Market Trends

According to the 2024 Mordor Intelligence market report, the global steel pipe market size is projected to reach USD 129.9 billion by 2027, registering a CAGR of 3.4% from 2022 (source). Growth is primarily driven by rising oil & gas exploration, urban construction demands, and advanced manufacturing in petrochemical, metallurgy, and water infrastructure sectors.

- Key segments: Welded pipe, seamless pipe, stainless steel welded pipe, and composite pipes

- Growth drivers: Durability, corrosion resistance, customized design, compliance with ISO/ANSI standards

- Prominent manufacturers: Leading composite pipe manufacturer players are focusing on overlay welding and multi-material cladding for extended service life

2023 Global Welded Pipe Output: ~140 million tons

Composite Pipe CAGR (2023–2027): 4.2%

Asia-Pacific Share: 41%

2. Types of Steel Pipes for Sale & Technical Comparison

| Type |

Materials |

Manufacturing Process |

Corrosion Resistance |

Typical Applications |

Standard Compliance |

| Welded Pipe |

Carbon steel, stainless steel |

ERW, SAW, LSAW |

Good (varies with material) |

Oil, Gas, Water, Structure |

API 5L, ISO 3183, ASTM A53 |

| Stainless Steel Welded Pipe |

304/316L/2205 Duplex |

TIG/Plasma/ERW |

Excellent |

Chemical, Marine, Food |

ASTM A312, ISO 9001, EN 10217 |

| Overlay Welding Clad Steel Pipe |

Base: Q235B, L450, X65

Clad: 304/316L/625/825 |

Overlay Cladding (SAW/CNC) |

Outstanding (multi-layer) |

Petrochemical, Power, Mining |

API 5LD, ISO 15590, DNV-GL |

| Composite Pipe |

Steel + Polymer/Lined Alloy |

Extrusion, Lining, Co-extrusion |

Very High |

Water, Oil & Gas, Industrial |

ISO 21809, ASTM F1545 |

Welded pipe manufacturing for demanding sectors

Welded pipe manufacturing for demanding sectors

3. Overlay Welding Clad Steel Pipe: Technical Parameters & Unique Advantages

Overlay Welding Clad Steel Pipe is engineered through advanced overlay welding technology, fusing a corrosion-resistant alloy layer onto a tough carbon steel base pipe. This process leverages both the structural strength of steel and the unparalleled corrosion/abrasion resistance of the cladding material. Certified under API 5LD and meeting ISO/ANSI/DNV standards, Lion Pipeline’s clad pipes ensure reliability even in the harshest industrial environments.

- Typical Structure: Carbon steel base + corrosion-resistant alloy cladding (e.g., 304, 316L, Inconel 625/825)

- Outside Diameters: 4”–60” (114mm–1524mm)

- Wall Thickness: 6–60mm (customized)

- Cladding Thickness: 3–12mm

- Length: Up to 18m (standard)

- Welding Process: Automatic Submerged Arc Welding (SAW), CNC Overlay, Laser Cladding

- Non-Destructive Testing: UT, RT, PMI (Positive Material Identification)

- Lifespan: 25–60 years depending on media and conditions (field-proven)

- Standards: API 5LD, ISO 15590, DNVGL-ST-F101, ANSI B31.3

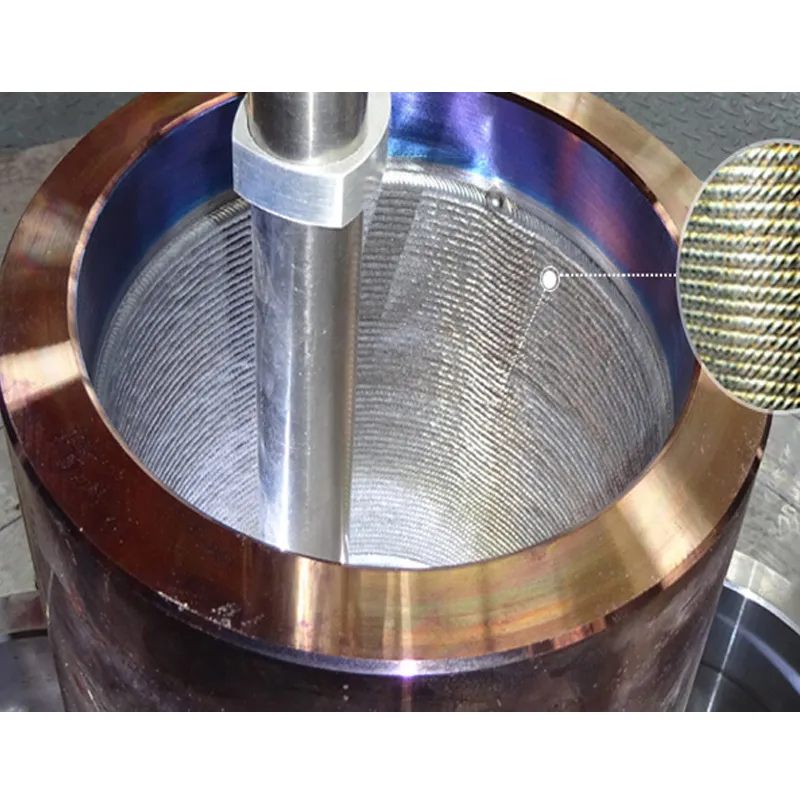

Overlay Welding Clad Steel Pipe microstructure (macro-section)

Overlay Welding Clad Steel Pipe microstructure (macro-section)

3.1 Detailed Manufacturing Process Flow

Overlay Welding Clad Steel Pipe Process:

1. Base steel preparation → 2. Surface cleaning & bevelling → 3. Overlay cladding (SAW/laser/CNC) → 4. Post-weld heat treatment → 5. Non-destructive testing (UT/RT/PMI) → 6. Hydraulic test → 7. Final machining & inspection → 8. Marking & packaging

3.2 E-Visual: Steel Pipes for Sale - Market Data & Technology Trends

3.3 Key Advantages of Overlay Welding Clad Steel Pipe

-

Corrosion and Wear Resistance: The overlay alloy (Ni/Cr based) offers up to 10x longer lifespan than ordinary carbon steel in H2S/CO2 or seawater exposure (Source: TWI Technical Paper).

-

Customizable Performance: Alloy combinations, wall thickness, and pipe diameter can be fully engineered per project.

-

Mechanical Integrity: Meets or exceeds ISO 15590/ANSI B31.3 impact and tensile benchmarks. Tested to 420MPa+ yield strength.

-

Cost Efficiency: Over 35% cost savings vs. solid alloy pipe of equivalent corrosion life.

-

International Standard Compliance: API, ISO, DNV, NACE compliant, backed by third-party test reports.

-

Full Traceability: Every clad pipe is marked for material, heat/lots, and NDT results as per industry best practices.

-

Green Production: Automated welding optimizes material use, reduces energy, and minimizes waste per ISO 14001 guidelines.

4. Welded Pipe, Stainless Steel Welded Pipe & Composite Pipe Manufacturer: Industry Benchmarking

| Product |

Base/Clad Materials |

Wall Thickness (mm) |

Corrosion Resistance Index |

Lifespan (years) |

Testing Applied |

Standard |

| Welded Pipe (carbon steel) |

Q235, S355 |

4–14 |

★★★☆☆ |

10–25 |

UT, Hydro, Visual |

API 5L/ASTM A53 |

| Stainless Steel Welded Pipe |

304, 316L |

3–10 |

★★★★★ |

20–40 |

PMI, Hydro, RT |

ASTM A312/EN10217 |

| Overlay Welding Clad Steel Pipe |

Q235B/X65 + 316L/625 |

6–60 |

★★★★★ |

25–60 |

PMI, UT, RT, Micro-eval |

API 5LD/ISO 15590 |

| Composite Pipe (steel-polymer) |

Carbon steel + PE/PP |

6–12 |

★★★★☆ |

15–30 |

Pressure, Peel, Bend |

ISO 21809 |

5. Custom Engineering: Pipeline Solutions & Delivery

- Consultation & Design: Full technical support from material selection to engineering drawings; in-depth review based on application (e.g. corrosive gas/oil, desalination, mining slurry, industrial water).

- Process Customization: Wall thickness, cladding alloy, NDT method can be individually specified.

- Quality & Compliance: All pipes undergo 100% hydro & ultrasonic testing, PMI verification, and are delivered with factory test reports (EN10204 3.1/3.2).

- Delivery Time: Typically 4–12 weeks ARO (After Receipt of Order), depending on specification & quantity.

- Warranty: Minimum 2 years for clad layer integrity and structural strength; extended warranties available for project contracts.

6. Application Scenarios & Use Cases

-

Petrochemical Pipelines: Transport of crude oil and refined products in highly corrosive H2S/CO2 service—demonstrated up to 58% lower maintenance vs. carbon steel after 15 years (Total, 2022).

-

Metallurgical Slurry Lines: Overlay Welding Clad Steel Pipe used in mining for mixed acid and abrasive ore slurries. Examples include the Magnesite Mining Project, reducing annual pipe replacement costs by over 60%.

-

Desalination Plants: Stainless steel and alloy-clad pipes withstand long-term exposure to seawater; DNV-GL evaluated performance exceeding 35 service years.

-

Power Plant Cooling/Water Systems: Composite and clad pipes deliver reliable service and energy savings via reduced scaling and longer operation cycles.

-

Municipal Water, Oil & Gas: International city water projects specified API-compliant clad pipe to meet stringent health (FDA) and longevity requirements.

User Feedback: “After replacing conventional welded pipes with clad pipes, we extended inspection intervals from 6 to 18 months, with zero downstream failures.”—Hydrocarbon Processing Plant, Oman, 2023

7. Professional FAQ: Steel Pipes for Sale Technical Q&A

Q1: What is the main benefit of overlay welding compared to solid alloy pipe?

Overlay welding enables a cost-effective combination of a robust carbon steel body with a corrosion-resistant clad layer (e.g., 316L, Inconel 625). This offers similar corrosion resistance as a solid-alloy pipe at 30-45% lower material cost, with additional customization possibilities.

Q2: Which international standards are critical for steel pipes for sale?

API 5LD, ISO 15590, DNVGL-ST-F101, and ASTM A clad/composite specifications are essential. Pipes are also certified for compliance with EN, ANSI, and (for water projects) FDA material requirements.

Q3: How is Positive Material Identification (PMI) performed on clad pipes?

PMI uses XRF or OES analyzers to verify the chemical composition of the clad alloy at various points. This ensures every length and weld meets specified grades (e.g., 316L min. 16.5% Cr, 10% Ni for corrosion resistance).

Q4: What is the difference between welded and seamless pipe?

Welded pipe is made by forming and welding steel plate/sheet, offering versatility in specifications and cost. Seamless pipe is produced by hot rolling/plug-mill extrusion and features higher uniformity and pressure resistance (vital for special applications), but typically at higher cost and limited lengths.

Q5: What are common wall thicknesses for Overlay Welding Clad Steel Pipe?

Wall thickness ranges from 6 to 60mm, with clad layers from 3mm upwards—customized per API/ISO project requirements and application (erosion/corrosion/media pressure).

Q6: How long is the typical delivery time for custom steel pipes for sale?

For standard steel pipes for sale in inventory: 1–3 weeks. For custom overlay/clad/composite specification: generally 5–12 weeks, depending on complexity, testing, and project volume.

Q7: What is the guarantee/warranty policy?

A 2-year warranty covers all manufacturing, material, and clad defects. Extended warranties (5–10 years) are available for approved projects. Lion Pipeline offers full after-sales technical support and on-site assistance for installation or troubleshooting.

8. Customer Service, Certifications, and Industry Authoritativeness

-

Industry Certifications: Products comply with API 5LD, DNV-GL, ISO 9001/14001/15590, and PED (European Pressure Equipment Directive). Third-party test reports (SGS/LR/TUV) accompany every shipment.

-

International Projects: Supplying projects in over 40 countries, including Shell, PetroChina, Saudi Aramco, and Veolia.

-

Customer Support: 24/7 online technical support, rapid logistics arrangements, and remote/on-site installation guidance.

-

After-Sales Commitment: Traceability, documentation, and regular follow-up ensure trouble-free use throughout the project lifespan.

-

Reference: For custom pipeline design or urgent requirement for steel pipes for sale, professional engineers provide immediate quotations and material advice.

References & Further Reading