In the vast landscape of industrial infrastructure, the integrity and reliability of piping systems are paramount. At the heart of many critical operations, from energy transportation to chemical processing, lie robust and durable components. Among these, carbon seamless steel pipes stand out as a foundational element, renowned for their superior strength, leak resistance, and adaptability to extreme conditions. Unlike their welded counterparts, seamless pipes offer an uncompromised structural integrity, making them indispensable for high-pressure, high-temperature, and corrosive environments. This article delves into the technical intricacies, manufacturing excellence, diverse applications, and strategic advantages that position these pipes as a cornerstone in modern industrial projects. We will explore key industry trends, detailed technical specifications, real-world application scenarios, and the critical factors in selecting a reliable carbon steel seamless pipe manufacturer, ensuring that B2B decision-makers and technical personnel are equipped with comprehensive knowledge to make informed procurement choices.

The global demand for high-performance piping solutions continues to surge, driven by expanding infrastructure development, energy exploration, and industrial modernization across various sectors. The inherent benefits of seamless steel, such as uniform wall thickness and absence of a weld seam, significantly reduce the risk of failure, contributing to enhanced operational safety and extended service life. Specific grades like SA106 steel are frequently specified for their excellent high-temperature service capabilities, crucial in power generation and petrochemical industries. Furthermore, the market is seeing a growing emphasis on sustainable manufacturing practices and pipes designed for energy efficiency and reduced environmental footprint. This evolution underscores the importance of choosing products that not only meet stringent performance criteria but also align with broader industry sustainability goals.

The production of carbon seamless steel pipes is a sophisticated process that begins with solid steel billets, ensuring a homogenous material structure free from impurities. The primary method for manufacturing seamless pipes is the rotary piercing (Mannesmann) process, where a solid steel billet is heated to high temperatures (typically 1200-1300°C) and then pierced by a rotary piercer over a mandrel. This creates a hollow shell, which is then further processed through a series of rolling mills (e.g., plug mills, mandrel mills, or stretch-reducing mills) to achieve the desired outer diameter (OD) and wall thickness (WT). This hot working process refines the grain structure of the steel, enhancing its mechanical properties, including tensile strength and toughness.

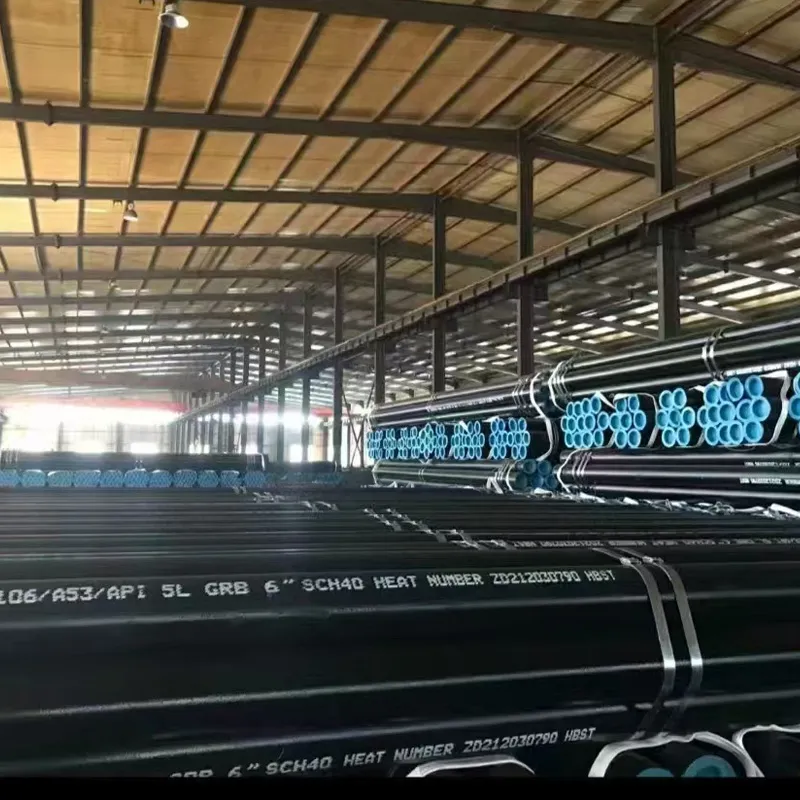

Following the hot rolling phase, the pipes undergo sizing, cooling, and straightening. Crucially, each pipe is subjected to rigorous quality control inspections. These include non-destructive testing (NDT) methods such as ultrasonic testing (UT), eddy current testing, and magnetic particle inspection (MPI) to detect any internal or surface flaws. Hydrostatic testing is also performed to verify the pipe's ability to withstand specified internal pressures, ensuring leak integrity. Adherence to international standards like ASTM A106 (for SA106 steel pipes commonly used in high-temperature service), ASTM A53, API 5L, and ISO 3183 is meticulously maintained throughout the manufacturing process. These standards dictate material composition, mechanical properties, dimensions, and testing protocols, ensuring the pipes meet the stringent demands of industries such as petrochemical, power generation, and oil & gas. The typical service life of a well-maintained carbon seamless steel pipe can exceed 30 years, showcasing their long-term value and reliability in critical applications.

Understanding the technical specifications of carbon seamless steel pipes is vital for proper material selection and application. These parameters define the pipe's physical dimensions, mechanical strength, and suitability for various operational conditions. Below is a comprehensive table outlining typical specifications for common grades:

| Parameter | Description/Typical Value |

|---|---|

| Material Grades | ASTM A106 Gr. B/C, ASTM A53 Gr. B, API 5L Gr. B/X42/X52, ASTM A179, ASTM A192 |

| Outer Diameter (OD) | 1/2 inch to 28 inches (DN15 to DN700), custom sizes available |

| Wall Thickness (WT) | SCH 10 to SCH XXS (2.77mm to 60mm), per ASME B36.10M |

| Length | SRL (Single Random Length 5-6m), DRL (Double Random Length 10-12m), fixed lengths up to 20m |

| Standards | ASTM, ASME, API, ISO, DIN, JIS, EN |

| Tensile Strength (Min.) | 415 MPa (60,000 psi) for A106 Gr. B |

| Yield Strength (Min.) | 240 MPa (35,000 psi) for A106 Gr. B |

| Working Temperature | Up to 593°C (1100°F) for certain grades like A106 |

| Corrosion Resistance | Good in general service; requires coating/lining for severe corrosive media |

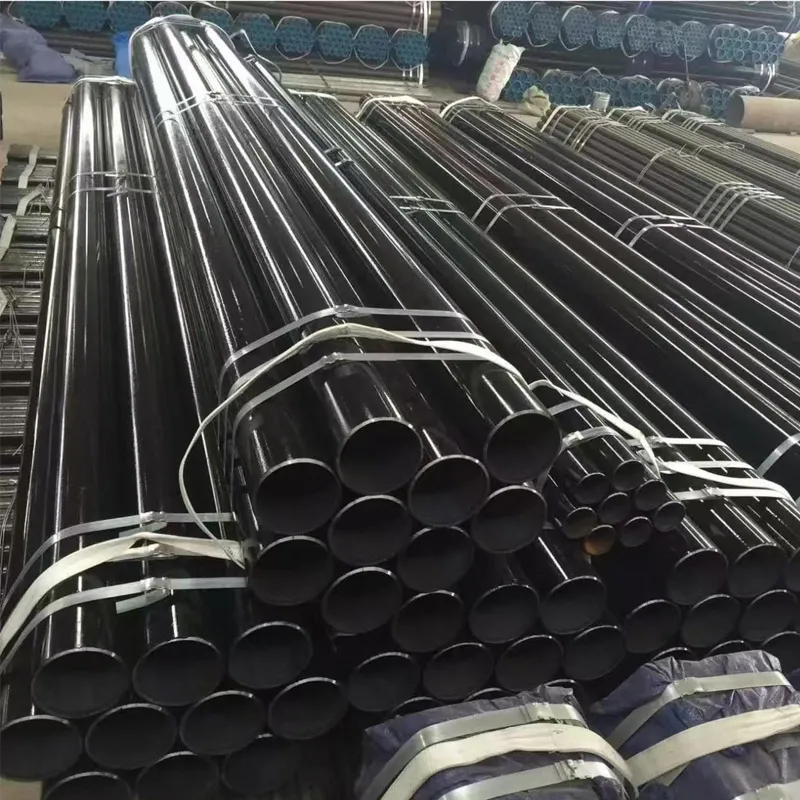

These specifications are crucial for engineers designing piping systems, as they dictate the pipe's capacity to handle internal pressure, external loads, and environmental conditions. For instance, SA106 steel, specifically grade B or C, is a common choice for high-temperature and high-pressure service in power plants and refineries due to its enhanced mechanical properties at elevated temperatures. The typical finish for these pipes is often referred to as black steel seamless pipe, which refers to the dark iron oxide scale coating formed on its surface during the manufacturing process, providing some initial corrosion resistance.

The robust nature of carbon seamless steel pipes makes them indispensable across a multitude of industries, where their reliability directly impacts operational safety and efficiency. In the Oil and Gas Industry, they are extensively used for conveying crude oil, natural gas, and refined petroleum products under high pressure and temperature conditions, both onshore and offshore. Their seamless construction minimizes the risk of leaks, which is critical in preventing environmental hazards and ensuring continuous supply. For example, in a deep-sea drilling application, SA106 Grade C pipes might be chosen for their superior tensile strength and resistance to external hydrostatic pressure.

The Petrochemical Industry relies heavily on these pipes for transporting corrosive chemicals, steam, and high-temperature fluids. The pipes’ ability to resist stress corrosion cracking and maintain structural integrity under extreme thermal cycling is vital for safety and plant uptime. In Power Generation, including thermal and nuclear power plants, carbon seamless steel pipes are integral components in boiler systems, steam lines, and heat exchangers, where they must withstand continuous high temperatures and pressures. Their excellent thermal conductivity and durability contribute to enhanced energy efficiency and reduced maintenance downtime, aligning with broader goals for sustainability and operational cost reduction.

Beyond energy, these pipes are crucial in Water Treatment and Supply Systems for transporting potable water and industrial effluents, offering long-term corrosion resistance when properly coated or lined. In Construction, they serve as structural components, piles, and conduits for various utilities, especially where high strength-to-weight ratio and durability are required. Their use in these diverse scenarios underscores their versatility and the critical role they play in sustaining global infrastructure. For instance, an urban water supply project might utilize black steel seamless pipe for its raw water transmission lines, leveraging its robust nature for reliable long-distance transport.

Selecting a reputable carbon steel seamless pipe manufacturer is as crucial as the product itself. A reliable manufacturer offers more than just pipes; they provide expertise, consistent quality, and comprehensive support. Key factors to consider include the manufacturer's experience and track record in the industry, their adherence to international quality standards such as ISO 9001, API Spec Q1, and specific product certifications like API 5L or ASTM. A strong commitment to quality is demonstrated through stringent material sourcing, in-house testing facilities (e.g., destructive and non-destructive testing), and traceability systems for every batch of pipes produced.

Leading manufacturers also provide extensive customization capabilities, allowing clients to specify precise dimensions, material grades (e.g., specific SA106 steel requirements), surface finishes, and end preparations to meet unique project demands. This includes offering various anti-corrosion coatings (e.g., FBE, 3PE), internal linings, and specialized heat treatments. Furthermore, a manufacturer's ability to provide timely delivery, transparent communication, and robust after-sales support (including technical assistance and warranty programs) significantly contributes to project success and minimizes potential disruptions. Reputable manufacturers often have a portfolio of successful case studies, demonstrating their proven capability to supply carbon seamless steel pipes for complex and demanding projects worldwide. Their long service years and partnerships with global engineering firms further solidify their authority and trustworthiness in the market.

Our unwavering commitment to quality is the cornerstone of our operations as a leading carbon steel seamless pipe manufacturer. We hold globally recognized certifications such as ISO 9001 for quality management systems and API 5L/5CT for oil and gas piping, underscoring our adherence to the highest international standards. Every batch of carbon seamless steel pipes undergoes stringent testing protocols, including ultrasonic flaw detection, hydrostatic pressure tests, and material chemical composition analysis, ensuring that each pipe meets or exceeds industry specifications like ASTM A106 Gr. B/C. Our robust quality control process, managed by experienced engineers, guarantees product reliability and traceability from raw material to final shipment.

We understand that timely delivery is critical for project timelines. Our advanced logistics and supply chain management ensure efficient delivery cycles, typically ranging from 15 to 45 days depending on order volume and customization requirements. Each product comes with a comprehensive warranty, affirming our confidence in our manufacturing excellence and providing our clients with peace of mind. Our dedicated customer support team is available to assist with technical queries, order tracking, and post-delivery support, ensuring a seamless experience. We prioritize building long-term partnerships based on trust, transparency, and a proven track record of delivering superior black steel seamless pipe solutions that withstand the test of time and demanding industrial environments.

A1: The primary advantage of carbon seamless steel pipes is their uniform structure without a welded seam. This eliminates the potential for weld seam failures, making them inherently stronger and more reliable, especially under high-pressure, high-temperature, or corrosive conditions. They offer superior integrity and better resistance to stress, corrosion, and fatigue, leading to a longer service life and enhanced safety in critical applications.

A2: ASTM A106 is a standard specification for seamless carbon steel pipes for high-temperature service. It is widely used in power plants, refineries, petrochemical plants, and other facilities where fluids are transported at high temperatures and pressures. Grades B and C are common, with Grade C offering slightly higher tensile strength and yield strength. It's a popular choice for boiler piping, pressure vessels, and superheater tubes.

A3: "Black steel seamless pipe" typically refers to carbon seamless steel pipes that have not been galvanized or coated after manufacturing. The "black" appearance comes from a dark iron oxide scale formed on its surface during the hot rolling manufacturing process. While this scale offers some initial corrosion protection, these pipes are generally used for non-potable water, oil, gas, or steam lines, and often require additional coating or painting for outdoor or highly corrosive environments.

A4: Quality assurance for carbon seamless steel pipes involves a range of tests. These include mechanical property tests (tensile, yield, elongation), chemical analysis, non-destructive testing (NDT) such as ultrasonic testing (UT), eddy current testing, and magnetic particle inspection (MPI) for internal and surface defects. Hydrostatic testing is also performed to ensure the pipe's pressure integrity. These tests comply with international standards like ASTM, API, and ISO.

A5: Yes, a reputable carbon steel seamless pipe manufacturer can provide extensive customization. This includes specific outer diameters, wall thicknesses, lengths, material grades (e.g., custom chemical compositions for SA106 steel variants), end finishes (beveled, plain), and internal/external coatings (e.g., FBE, 3PE, internal epoxy lining) to suit the precise requirements of your project, including enhanced corrosion resistance or flow efficiency.

The selection of high-quality carbon seamless steel pipes is a critical decision for any industrial project, directly impacting safety, operational efficiency, and long-term cost-effectiveness. Their inherent strength, superior integrity due to the absence of a weld seam, and adaptability to extreme conditions make them the preferred choice for demanding applications across the oil and gas, petrochemical, power generation, and water treatment sectors. Whether it's the high-temperature resilience of SA106 steel or the robust simplicity of a black steel seamless pipe, the consistent performance and reliability of these products are undeniable.

Partnering with an experienced and certified carbon steel seamless pipe manufacturer ensures access to products that meet stringent international standards, backed by comprehensive quality control, technical expertise, and responsive customer support. By investing in these foundational components, industries can secure resilient infrastructure that minimizes risks, maximizes uptime, and contributes to sustainable industrial growth. We are committed to providing unparalleled piping solutions that power progress and build trust, one reliable pipe at a time.

Overlay Welding Clad Steel Pipe

Where to Buy Stainless Steel Pipes and Tubing for Sale Together

The Future of Smart Flange Technology

Tee Pipe Fitting in Industrial Process Piping

Prefabricated Pipe in Shipbuilding Applications

How Anti Corrosion Pipe Extends Pipeline Lifespan

Cts Pipe Fittings for Potable Water Systems

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.