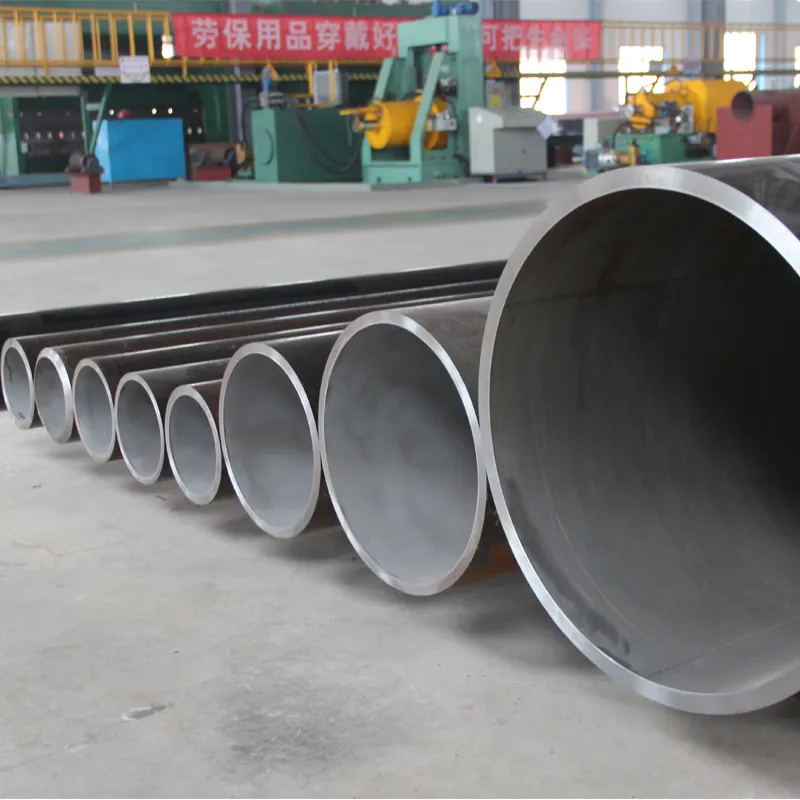

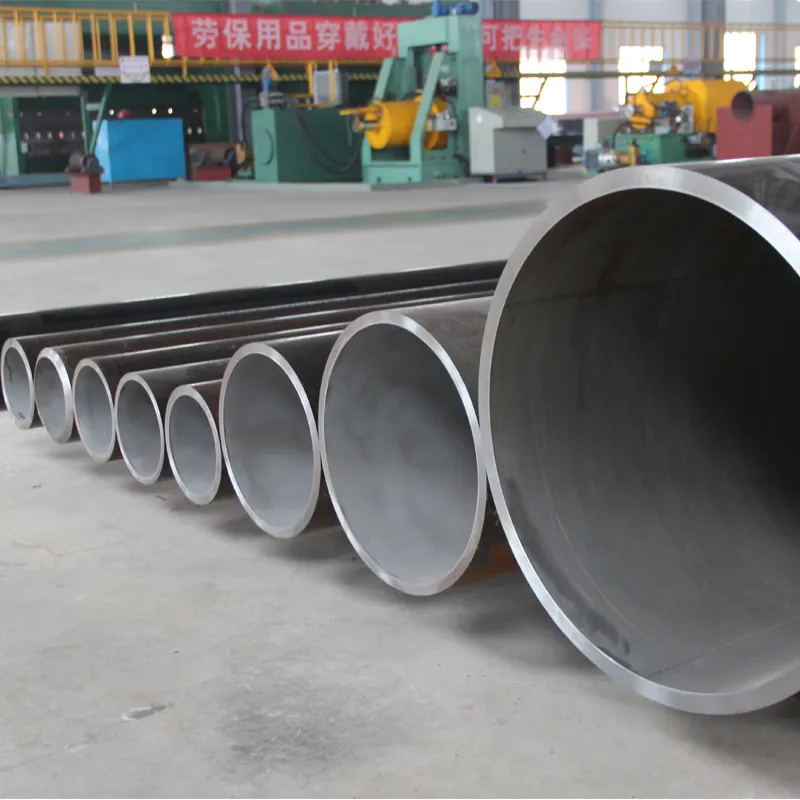

Composite pipes have become a cornerstone of the modern industrial pipeline sector. Combining the mechanical strength of metals with the durability and resistance advantages of composite materials,

Mechanical Clad Steel Pipe marks a breakthrough in the offerings of advanced composite pipe technology.

This article offers an in-depth analysis of composite pipe and related solutions, such as steel pipe manufacturer market trends, technical parameters, application scenarios, supplier comparison, customization, real-world case studies, and more.

1. Industry Trends in Composite Pipe & Steel Pipe Manufacturing

The composite pipe industry is projected to achieve a CAGR of over 6.2% between 2024 and 2030. According to MarketsandMarkets, robust demand from sectors such as oil & gas, petrochemical, municipal water supply, and industrial manufacturing is driving technological transformation and material innovation, with Mechanical Clad Steel Pipe emerging as a leading solution.

- Key Growth Drivers: Corrosion resistance, lightweight construction, longevity, easy installation, and the need for high-performance in aggressive environments.

- Top Steel Pipe Manufacturers: Tenaris, Lion Pipeline, Vallourec, TMK, ChelPipe, and more actively invest in composite and mechanical pipes.

- Regional Market: APAC dominates due to infrastructure upgrades; strong growth also in North America and Middle East.

2. Understanding Mechanical Clad Steel Pipe Technology

The Mechanical Clad Steel Pipe uses advanced cladding techniques—combining high-strength carbon or alloy steel with corrosion-resistant alloys (CRAs)

such as stainless steel or nickel, via mechanical bonding. It achieves optimal mechanical performance, cost-efficiency, and long-term anti-corrosion

capacity, outperforming conventional steel pipes in hostile environments.

Learn more at the

Mechanical Clad Steel Pipe official page.

2.1 Process Flowchart: Mechanical Clad Composite Pipe Manufacturing

Raw Material

(Base + CRA Layer)

Carbon steel / Alloy plate &

corrosion-resistant alloy

Surface Preparation

Shot blasting, degreasing,

NDT cleaning

Mechanical Cladding

High-pressure rolling,

bonding by large presses

Pipe Forming & CNC Machining

Roll/form into pipe,

edge CNC cutting

Welding & Heat Treatment

GTAW/SAW Welding, annealing,

NDT & hydraulic tests

Final Inspection & Shipping

ISO/ANSI checks

Surface finish, sizes

2.2 Key Material Grades & Structure

- Base layer: Carbon steel (API 5L X65/Gr.B/ASTM A516), Alloy steel

- Clad/CRA layer: SS304, SS316L, Inconel 625, Alloy 825, Monel 400, or duplex stainless steels

- Bonding: Achieved via mechanical rolling – full metallurgical bonding, 100% interface contact, tested by ultrasonic NDT

- Wall thickness ratio: Typically 85-92% base, with 8-15% CRA layer

2.3 Testing, Standards & Quality Assurance

- International Standards: ISO 3183, ASTM A clad series, ASME B31.3/31.8, API 5LD, ANSI/ASME

- Testing: Ultrasonic testing (UT), eddy current, hydrostatic pressure, mechanical impact, and corrosion resistance tests

- Certifications: Provided with ISO 9001/14001, PED, DNV-GL, and more from reputable steel pipe manufacturers

- Guaranteed service life: 30+ years (in aggressive oil, gas, petrochemical or seawater environments)

- Traceability: 100% digital traceability and documentation per batch/pipe

3. Technical Parameters: Composite Pipe vs. Mechanical Steel Pipe

The following table aggregates and compares the major technical parameters of composite pipe from leading steel pipe manufacturers worldwide.

Mechanical Clad Steel Pipe shows significant advantages in mechanical strength, corrosion resistance, and lifecycle cost.

| Parameter |

Mechanical Clad Steel Pipe |

Traditional Steel Pipe |

Plastic Composite Pipe |

| Pipe Standard |

ISO 3183 / API 5LD / ASME B31.8 |

API 5L / ASTM A106 |

ISO 4437, ASTM F714 |

| Diameters (mm) |

DN 50–1200 |

DN 15–1800 |

DN 50–630 |

| Working Pressure (MPa) |

up to 25.0 |

up to 20.0 |

up to 1.0 |

| Max Temperature (°C) |

up to 380 |

up to 340 |

80–100 |

| 耐腐食性 |

Excellent (Surface & Interface) |

Poor to moderate |

High (Internal), moderate(External) |

| Joining Method |

Welded / Flanged |

Welded |

Socket / Electro-fusion |

| Life Cycle (Years) |

≥30 |

10~18 |

15~30 |

| Key Application |

Oil, Gas, Petrochemical, Seawater |

General Industry, HVAC |

Water, Gas (low/mid pressure) |

4. Technology Advantages & Product Highlights

- Cost-Efficiency: Combines the low cost of carbon steel base with the premium corrosion resistance of CRAs, providing significant total cost savings over full CRA pipe.

- Superior Mechanical Properties: High yield strength, low thermal expansion, negligible mechanical delamination even after 30 years of operation.

- Extended Service Life: Demonstrated 30+ year durability in seawater injection, chemical transport, and high-H2S oil & gas service—validated by field studies and lab simulation.

- Easy Customization: Modular fabrication to any diameter, layer, or length; supports on-site or factory customization.

- International Certification: ISO, ANSI/ASME, DNV-GL approved. Full documentation, batch traceability, third-party witness testing.

Studies (e.g., Recent Developments on Clad & Composite Pipe) prove that composite pipe greatly reduces overall lifecycle cost despite slightly higher procurement price compared to bare steel pipe.

5. Supplier & Manufacturer Comparison

Leading Composite Pipe & Steel Pipe Manufacturers

| Supplier |

Product Family |

認証 |

Major Project |

Location |

| Lion Pipeline |

Mechanical Clad Steel Pipe, Lined/Overlay Pipes |

ISO 3183, API 5LD, DNV-GL |

CNPC CNOOC deep sea pipeline |

中国 |

| Tenaris |

Clad/CRA pipe, Welded steel pipe |

ISO 9001, API Q1 |

Petrobras subsea, Shell projects |

Italy/Global |

| Vallourec |

Mechanical alloy, Arc welded pipes |

ISO 14001, EN10216 |

Total offshore, ADNOC refineries |

France |

| TMK |

Clad, Mechanical steel pipe |

ASME B31.8, GOST |

Middle East, Gazprom projects |

ロシア |

Industry Certifications: All above suppliers offer ISO and API certified pipes, traceable documentation, and third-party (SGS/BV) witness testing for most critical projects.

6. Customization & Delivery Solutions

- Diameter Range: 50mm to 1200mm for mechanical clad composite pipe (others on request)

- CRA Thickness: 2mm to 8mm (customizable: 316L, 825, Monel, etc.)

- Length: 6m, 12m, or tailored to site/delivery requirement

- Accessories: Flanges, elbows, reducers, caps matching the pipeline project

- Project Support: 3D layout, technical consultation, on-site welding support

- Lead Time: Standard: 35-50 days; Fast-track: 21–28 days for urgent projects

- Guarantee: 24–36 months warranty; 100% replacement for defects

7. Application Scenarios & Client Case Studies

7.1 Oil & Gas Upstream

Mechanical Clad Steel Pipe has been extensively used in offshore and onshore oilfields to transport multi-phase fluids, saline formation water, and high-pressure gas. For example, a Middle East NOC deployed 64km of 12" x 9.52mm 316L clad composite pipe, resulting in zero corrosion failure after 7 years of 150°C, 10.2 MPa operation.

7.2 Petrochemical & Refinery

World-leading refineries employed mechanical steel pipe in process lines handling H2S and organic acids. Maintenance downtime dropped by 80% after replacement of traditional carbon steel pipelines.

7.3 Municipal & Water Treatment

In Asia, a metropolitan water company selected clad composite pipelines for an 18km potable water tunnel project. This guaranteed 100% compliance with WHO water quality standards and reduced leakage by 55% compared to legacy steel pipe installations.

7.4 Metallurgy & Pulp Industry

At a major steelworks, mechanical clad piping replaced lined carbon steel for hydrochloric acid recycling. Annual cost saving exceeding $350,000, elimination of yearly pipe changeouts.

Customer Experiences:

- “Switching to Mechanical Clad Steel Pipe halved our maintenance costs and improved system availability from 91% to 99.4%.” — Operations Chief, CNPC subsidiary

- “No wall thinning or delamination after 5 years continuous acid service. Flawless weld seam finish.” — QA Manager, Asian Chemical Refinery

8. Third-Party Authority Reports & Certifications

- API and DNV test reports show mechanical clad composite pipes meet or exceed minimum test requirements even in sour service (H2S, CO2), with no microcracks after 7,000+ thermal cycles.

- Major international operators (Shell, ADNOC, ConocoPhillips) have authorized mechanical clad pipe as a standard replacement for full-CRA and carbon steel pipeline systems.

- ISO 3183 and EN 15189 compliance is proven in random sampling for wall thickness and corrosion interface strength.

9. FAQ: Technical Terms & Professional FAQ

Q1: What is the main material used in a composite pipe?

A: A mechanical clad composite pipe comprises a carbon/aloy steel base and a corrosion-resistant alloy (CRA) cladding (e.g., 316L, Inconel 625).

Q2: What are the typical wall thicknesses and diameters available?

A: Standard OD range: 50–1200 mm; clad thickness: 2–8 mm; base steel per project spec.

Q3: What welding methods are used for installation?

A: GTAW (TIG), SAW, or multi-pass automatic welding per ASME B31.8 and API 5LD standards.

Q4: How is corrosion resistance tested in mechanical steel pipe?

A: By accelerated salt spray, immersion, and periodic surface potential (ASTM B117), plus ultrasonic non-destructive examination (NDE) of the clad interface.

Q5: What is the minimum bending radius when installing composite pipe?

A: Usually ≥25 times the pipe OD (as required in ISO/EN standards), but dependent on base metal grade and wall.

Q6: Are there restrictions on transporting potable water?

A: No; mechanical clad steel pipe with 316L, 304L or Alloy 825 meets FDA and WHO requirements under EN 15189.

Q7: What delivery and quality guarantees are provided?

A: Pipes are shipped with full EN/ISO/ASME certificates, NDT test reports, and a standard 24–36 month warranty, plus free lifetime technical support for composite pipe customers.

10. Conclusion

Mechanical Clad Steel Pipe stands at the forefront of composite pipe technology—delivering performance, reliability, and sustainability across multiple industries.

Backed by stringent standards, real-world project experience, and fully customizable support, it is the top choice for oil & gas, petrochemical, water, and metallurgical pipelines.

“Research in journals like International Journal of Precision Engineering and Manufacturing and Journal of Cleaner Production confirm: advanced composite pipe manufacturing,

including mechanical clad processes, is reshaping the global pipeline landscape with lower cost, higher reliability, and longer life cycles.”

- Referenced from Eng-Tips Forum and ResearchGate