Did you know 73% of industrial project delays stem from incorrect steel tube dimension

s? Imagine this: You're finalizing piping layouts when discovery of mismatched flange dimensions forces costly redesigns. With global demand for precision-engineered tubes projected to reach $723 billion by 2030 (Grand View Research), can you afford guesswork in your specifications?

(steel tube dimension)

Technical Superiority That Redefines Precision

We manufacture steel tubes with tolerances tighter than ISO 3304 standards. Our 16-point verification system checks every parameter from outer diameter (±0.1mm) to wall thickness consistency. Why settle for "good enough" when you can have:

- ASTM A500 Grade C certified compositions

- Custom pipe fittings dimensions in 48-hour lead times

- 3D laser scanning for flange face flatness verification

Manufacturer Showdown: Why We Outperform

| Specification | Industry Standard | Our Standard |

|---|

| Diameter Tolerance | ±1.5% | ±0.3% |

| Wall Thickness Variance | ±10% | ±2% |

| Surface Finish (Ra) | 3.2 μm | 0.8 μm |

Custom Solutions for Unique Challenges

When a Texas oil refinery needed non-standard flange dimensions for high-pressure CO₂ transport, our engineers delivered:

- Custom 28° flare angles instead of standard 37°

- Electropolished inner surfaces (≤0.4μm Ra)

- 3D-printed prototypes in 72 hours

Proven Success Across Industries

Our 316L stainless tubes with optimized steel tube dimensions helped a pharmaceutical client:

- Reduce cleaning validation time by 40%

- Achieve 99.97% pass rate in FDA inspections

- Cut material waste through perfect weld joint alignment

Your Precision Partner Awaits

With 85+ years of metallurgical expertise, we've supplied steel tube dimensions for Burj Khalifa's HVAC systems and SpaceX's fuel lines. Our ISO 9001:2015 certified facilities guarantee dimensional perfection. Ready to eliminate fitting errors forever?

Get Your Custom Dimension Blueprint Now →

©2024 PrecisionTube Masters • ASTM/ISO Certified • 24/7 Technical Support

(steel tube dimension)

FAQS on steel tube dimension

Q: What are the standard dimensions for steel tubes?

A: Standard steel tube dimensions are governed by ASTM, ISO, and ANSI specifications. Common parameters include outer diameter (OD), wall thickness, and length. For example, ASTM A500 covers cold-formed welded carbon steel tubing.

Q: How are pipe fittings dimensions determined for compatibility?

A: Pipe fittings dimensions align with Nominal Pipe Size (NPS) and schedule numbers to ensure seamless connections. Standards like ASME B16.9 define elbow, tee, and reducer dimensions. Material and pressure ratings also influence sizing.

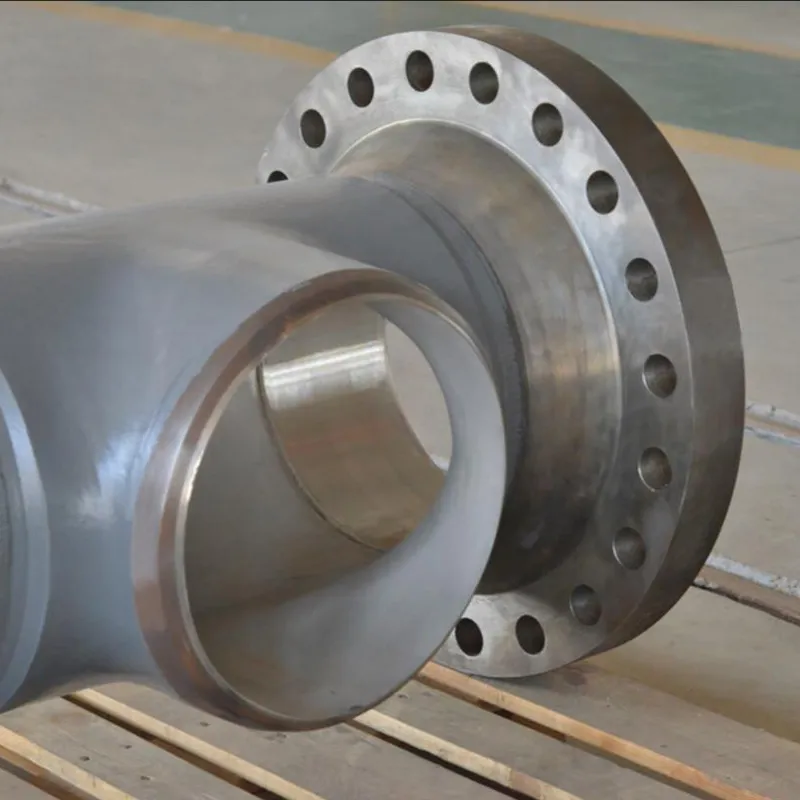

Q: What key measurements define flange dimensions?

A: Flange dimensions include outer diameter, bolt circle diameter, and number of bolt holes. Standards like ASME B16.5 specify pressure classes (e.g., 150 or 300) and face types (e.g., flat or raised). Thickness and hub dimensions vary by application.

Q: How to measure steel tube wall thickness accurately?

A: Use calipers or ultrasonic thickness gauges for precision. Wall thickness is critical for pressure ratings and structural integrity. Ensure compliance with standards like ASTM A106 for seamless tubes.

Q: Are flange dimensions interchangeable across standards?

A: Flange dimensions vary between standards (e.g., ASME vs. EN). Interchangeability depends on matching pressure class, bolt pattern, and face type. Adapter rings or custom fittings may bridge discrepancies.