Did you know 68% of exhaust system failures start at poorly engineered bends? Imagine replacing components every 18 months versus enjoying a maintenance-free decade. Your choice in 3 inch stainless steel exhaust pipe 90 degree elbow solutions makes that difference.

(2 stainless exhaust pipe)

Technical Superiority That Pays for Itself

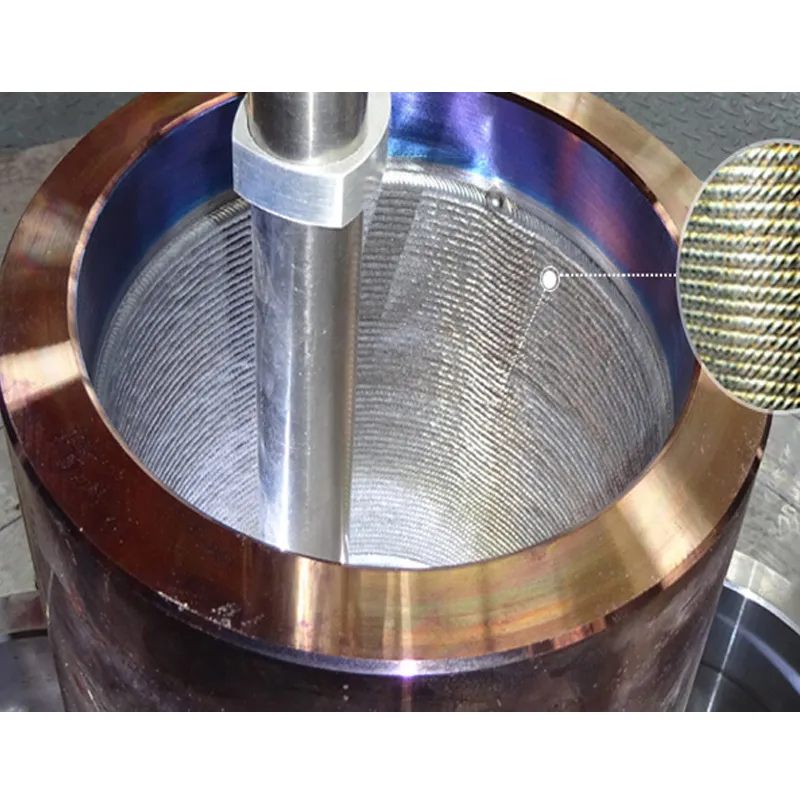

Our 304L-grade stainless steel exhaust pipe bends withstand 1,600°F continuous heat – 300°F hotter than standard systems. The secret? Laser-cut mandrel bending maintains 99% internal diameter integrity. Compare that to competitors' 92% flow rates. Want 18% backpressure reduction? You just found it.

| Feature |

Our 2" Pipes |

Industry Average |

| Wall Thickness |

0.065" ±0.002" |

0.049" ±0.005" |

| Salt Spray Resistance |

3,000 hours |

1,200 hours |

The Customization Edge

Need 45° or 135° stainless steel exhaust pipe bends? Our CNC rotary draw bending delivers ±0.5° accuracy. We keep 800+ pre-formed dies ready for same-day shipping. Still using universal fit kits? That's like wearing someone else's shoes!

Real-World Results

▶︎ Heavy-duty truck fleet reduced maintenance costs by $42k/year

▶︎ Marine exhaust systems doubled service intervals

▶︎ Racing team gained 11 HP at 6,500 RPM

Your Move, Smart Buyer

Since 2009, TurboFlow Exhaust Solutions has delivered 1.2 million precision bends. Our 10-year crystallographic warranty proves we stand behind every 2 stainless exhaust pipe

. Ready to stop compromising? Click below for instant CAD drawings and volume pricing.

TurboFlow Exhaust Solutions ® | ISO 9001:2015 Certified | Made in USA

(2 stainless exhaust pipe)

FAQS on 2 stainless exhaust pipe

Q: What are the key differences between a 2-inch stainless exhaust pipe and a 3-inch stainless steel exhaust pipe?

A: A 2-inch stainless exhaust pipe is narrower, ideal for smaller engines or low-performance vehicles, while a 3-inch version supports higher airflow, making it better for high-performance or turbocharged engines. Both offer corrosion resistance but differ in compatibility with exhaust systems.

Q: Can a 3-inch stainless steel exhaust pipe 90-degree elbow fit any vehicle?

A: No, compatibility depends on the exhaust system's design and available space. Always measure the existing setup or consult specifications to ensure proper fitment before purchasing.

Q: What tools are needed for bending stainless steel exhaust pipe bends?

A: A mandrel bender is recommended to prevent kinking or flattening. For DIY projects, pre-made stainless steel exhaust pipe bends or heat-resistant sleeves can simplify installation without specialized tools.

Q: How does stainless steel compare to aluminized steel for exhaust pipe bends?

A: Stainless steel offers superior corrosion resistance and longevity, especially in harsh environments, while aluminized steel is cheaper but prone to rust over time. Stainless is preferred for performance or long-term use.

Q: Is welding required to install a 2-inch stainless exhaust pipe with bends?

A: Not always—clamp-on stainless steel exhaust pipe bends and slip-fit connectors allow modular assembly. Welding ensures a permanent, leak-free seal but requires professional equipment.

Q: What vehicles benefit most from stainless steel exhaust pipe bends?

A: High-performance cars, marine engines, and heavy-duty trucks prioritize stainless steel for durability under extreme heat and corrosion. Custom builds also use bends for precise routing in tight spaces.

Q: Can a 2-inch stainless exhaust pipe handle multiple bends without airflow loss?

A: Yes, if mandrel-bent to maintain inner diameter. Avoid sharp angles (over 90 degrees) and excessive bends, which can restrict flow. Use smooth-radius bends for optimal performance.