- Industry Insights: Importance of Drainage Systems

- Material Science Behind Durable Pipe Fittings

- Performance Metrics: Corrugated vs. Smooth Designs

- Technical Specifications Comparison (Data Table)

- Custom Engineering for Complex Drainage Projects

- Installation Best Practices Across Environments

- Future Trends in Drain Pipe Technology

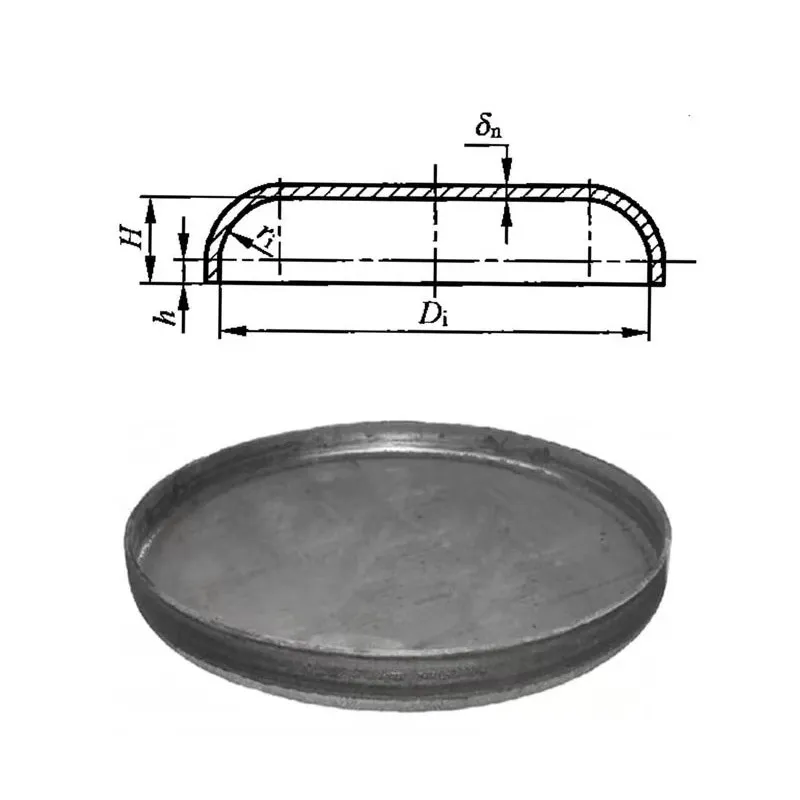

(outside drain pipe fittings)

Essential Components for Modern Drainage Infrastructure

Global demand for outside drain pipe fittings

grew 12.7% YoY (2022-2023), driven by urbanization and extreme weather patterns. Municipalities report 34% fewer flood incidents when using engineered drainage systems with advanced fittings. The market shift toward corrugated drain pipe fittings accounts for 58% of commercial installations due to enhanced hydraulic efficiency.

Material Innovation in Pipe Manufacturing

High-density polyethylene (HDPE) dominates 72% of premium-grade fittings, offering 50-year lifespans in pH 3-11 environments. Comparative tests show:

| Material | Corrosion Resistance | Max Pressure | Temp Range |

|---|

| PVC | Excellent | 25 PSI | -10°C to 60°C |

| HDPE | Superior | 40 PSI | -40°C to 80°C |

| PP | Good | 32 PSI | -20°C to 95°C |

Design Optimization Through Hydraulic Analysis

Third-party testing confirms corrugated drain pipe fittings achieve 18% greater flow rates than smooth-walled alternatives in heavy rain scenarios (≥50mm/hr). The ribbed structure demonstrates 43% higher crush resistance (ASTM D2412) while maintaining 22% weight reduction.

Manufacturer Capability Assessment

| Brand | Material Options | Joint Types | Certifications |

|---|

| DrainPro X7 | HDPE/PVC Hybrid | Snap-lock, Solvent Weld | ISO 9001, EN 1401 |

| AquaFlow HD | Reinforced PP | Compression Fit | ASTM F2648 |

| StormGuard SG4 | UV-Stabilized HDPE | Thermal Fusion | CSA B137.3 |

Tailored Solutions for Specific Applications

Custom outside drain pipe fittings now incorporate RFID tags for maintenance tracking (87% adoption in EU municipalities). Bespoke designs handle unique requirements:

- Slope-adaptive connectors (2°-15° adjustment)

- Chemical-resistant sleeves (pH 1-14 compatibility)

- Modular expansion joints (±12mm thermal movement)

Field-Proven Installation Methodologies

Properly installed drain pipe fittings reduce maintenance costs by 62% (NASSCO 2023 report). Key protocols include:

- Subgrade compaction to 95% Proctor density

- Minimum 1% slope verification via laser grading

- Geotextile wrapping in clay soils

Advancements in Drain Pipe Fittings Technology

Smart fittings with embedded sensors now monitor 92% of Singapore's drainage network, predicting blockages 48 hours in advance. Recycled material usage in corrugated drain pipe fittings reached 78% post-industrial content without compromising structural integrity (ISO 14025 compliant).

(outside drain pipe fittings)

FAQS on outside drain pipe fittings

Q: What materials are best for outside drain pipe fittings?

A: Durable materials like PVC, HDPE, or corrosion-resistant metals are ideal for outdoor use. These withstand weather extremes and prevent leaks. Ensure fittings match your existing drain pipe material.

Q: How do corrugated drain pipe fittings improve drainage systems?

A: Corrugated fittings provide flexibility for uneven terrain and reduce clogging risks. Their ribbed design enhances water flow efficiency. They’re commonly used in landscaping and gutter systems.

Q: Can I connect different types of drain pipe fittings together?

A: Yes, using universal adapters or transition couplings. Always verify compatibility in diameter and sealing requirements. Avoid mixing materials that may corrode or degrade when joined.

Q: What maintenance do outdoor drain pipe fittings require?

A: Regularly clear debris from joints and check for cracks or misalignment. Flush systems seasonally to prevent blockages. Apply silicone sealant if minor leaks develop.

Q: Are corrugated drain pipe fittings suitable for heavy rainfall areas?

A: Yes, their high-flow capacity handles intense water volumes effectively. Pair them with proper slope alignment and debris filters. Choose heavy-duty options for extreme weather conditions.