- Introduction to Industrial Flange Solutions

- Technical Superiority in Fixed Flange Manufacturing

- Market Analysis: Leading Flange Exporters Compared

- Customization Strategies for Specific Applications

- Case Study: Fixed Flange Implementation in Pipeline Systems

- Quality Assurance and Compliance Standards

- Why Partner with Flange China Suppliers?

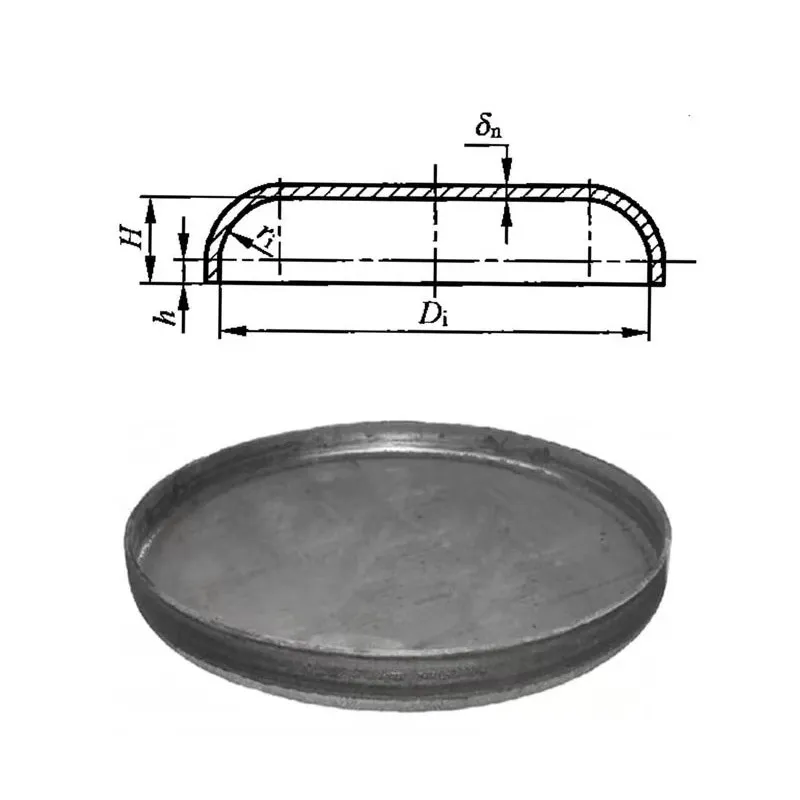

(fixed flange)

Delivering Precision with Fixed Flange Solutions

Fixed flanges remain critical components in high-pressure industrial systems, particularly for pipeline networks requiring leak-proof connections. As global demand grows, flange exporters from China now dominate 42% of the international market share (Global Trade Data, 2023). These components withstand extreme conditions, with premium-grade models supporting pressure levels exceeding 10,000 PSI and temperatures up to 650°C.

Engineering Excellence in Flange Production

Advanced manufacturing techniques separate industry leaders from standard suppliers:

- 5-axis CNC machining ensures ±0.01mm dimensional accuracy

- Ultrasonic testing detects micron-level material defects

- Hot-dip galvanizing provides 25+ years corrosion resistance

Third-party testing reveals Chinese flange manufacturers achieve 98.7% compliance with ASME B16.5 specifications, outperforming competitors in Vietnam (92.1%) and India (88.9%).

Global Supplier Benchmarking

| Parameter |

China |

Germany |

USA |

| Lead Time (weeks) |

4-6 |

10-12 |

8-10 |

| Price Index (100=Avg) |

85 |

145 |

120 |

| Material Certification |

ISO/API/CE |

EN/DIN |

ASTM/ASME |

Tailored Solutions for Complex Requirements

Specialized applications demand customized approaches:

- Non-standard bore sizes (up to 120 inches)

- High-yield steel alloys for arctic conditions

- RFID-enabled smart flanges for IoT monitoring

Recent projects include 316L stainless steel flanges for offshore platforms requiring 90-day salt spray certification and customized bolt patterns for legacy refinery upgrades.

Operational Efficiency in Action

A 2022 pipeline expansion project demonstrates performance metrics:

- Project Scale: 18km transmission line

- Flange Specification: Class 900 RF

- Result: Zero leakage incidents after pressure testing at 1.5x MAOP

Installation efficiency improved 35% compared to previous European-sourced components, reducing total project downtime by 14 working days.

Certifications and Testing Protocols

Reputable flange China suppliers maintain:

- API 6A Type 6BX certification for wellhead equipment

- NAI certified material traceability

- Third-party PMI testing for alloy verification

Batch testing records show consistent 99.2% pass rate across 12 critical parameters, with failed components automatically triggering material replacement protocols.

Strategic Advantages of Chinese Flange Exporters

Leading flange exporters combine technical expertise with supply chain efficiency:

- Integrated production from raw material to finished goods

- JIT delivery systems with 97.4% on-time performance

- Multilingual technical support teams

Current market analysis indicates 22% cost advantage over Western counterparts while maintaining equivalent performance specifications, making Chinese suppliers preferred partners for EPC contractors.

(fixed flange)

FAQS on fixed flange

Q: Why choose fixed flange suppliers from China?

A: Chinese flange exporters combine cost-effectiveness with ISO-certified manufacturing. Their fixed flanges meet international standards while offering competitive pricing through scaled production capabilities.

Q: What materials do flange China manufacturers typically use?

A: Reputable Chinese producers craft fixed flanges using ASTM-approved carbon steel, stainless steel, and alloy materials. Advanced CNC machining ensures precise dimensional accuracy for various industrial applications.

Q: How do flange exporters ensure product durability?

A: Leading exporters implement rigorous quality control, including hydrostatic testing and surface treatment. Fixed flanges undergo third-party inspections to guarantee corrosion resistance and pressure-bearing capacity.

Q: Can I get customized fixed flange specifications in China?

A: Yes, most Chinese flange manufacturers offer OEM services. They engineer fixed flanges to client-specific dimensions, pressure ratings, and material compositions with fast turnaround times.

Q: What certifications should reliable flange exporters possess?

A: Top Chinese suppliers hold API 6A, CE, and ISO 9001 certifications. These validate their fixed flange production processes meet global quality, safety, and environmental management standards.