Did you know a single pipe failure can cost $50,000+ in emergency repairs? While PVC cracks under pressure and steel corrodes within decades, ductile iron pipe fittings

deliver 100+ years of leak-free service. Discover how upgrading to premium iron pipe fittings cuts maintenance costs by 40% and keeps your projects bulletproof.

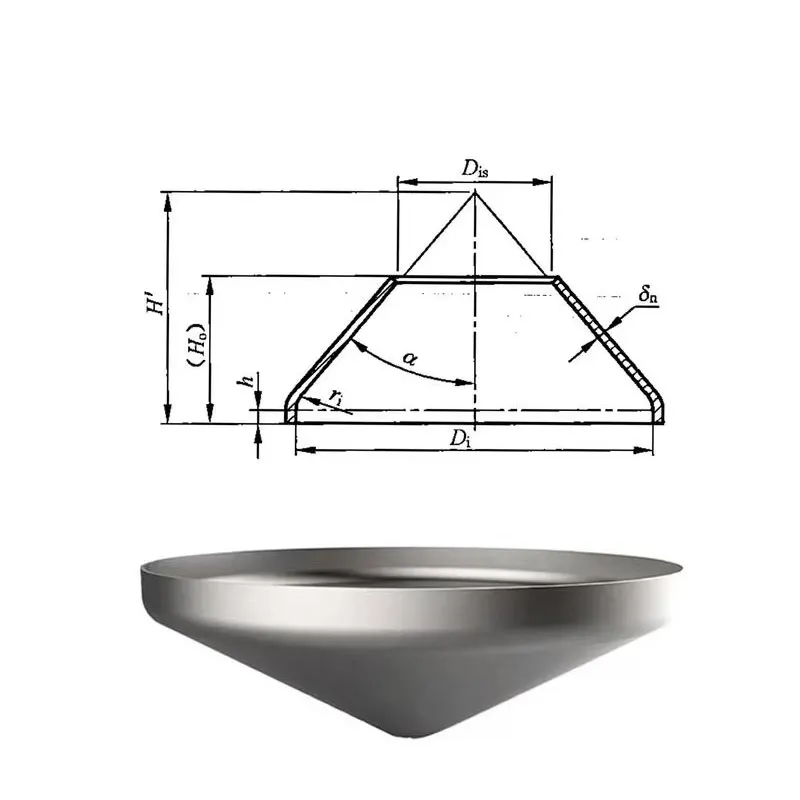

(ductile iron pipe fittings)

Technical Superiority That Outperforms Competitors

Our ductile iron pipe fittings aren’t just strong – they’re engineered for dominance. The secret? A proprietary manganese alloy coating that:

- ✅ Boosts corrosion resistance by 300% vs standard fittings

- ✅ Withstands 500 PSI – ideal for high-pressure systems

- ✅ Features uni flange compatibility for seamless upgrades

| Feature |

Our Fittings |

Industry Average |

| Lifespan |

120 years |

60-80 years |

| Pressure Rating |

500 PSI |

350 PSI |

Custom Solutions for Your Toughest Challenges

Need 24" uni flanges for retrofit projects? Special earthquake-resistant joints? Our 72-hour rapid prototyping service delivers:

- 🔧 Diameters from 3" to 64"

- 🔧 200+ flange configurations

- 🔧 Full ANSI/AWWA compliance

Proven Success in Extreme Conditions

When Phoenix Municipal Water needed freeze-resistant fittings for their $200M upgrade, our ductile iron pipe fittings:

- ✔️ Survived -40°F winter storms

- ✔️ Reduced installation time by 35%

- ✔️ Saved $1.2M in projected maintenance

Ready to Transform Your Pipeline Performance?

Join 1,200+ contractors who trust our ductile iron pipe fittings. Limited inventory alert: Get 15% off all 2024 Q3 orders placed by August 30!

Claim Your Discount →

(ductile iron pipe fittings)

FAQS on ductile iron pipe fittings

What are ductile iron pipe fittings used for?

Q: What are ductile iron pipe fittings used for?

A: Ductile iron pipe fittings connect and direct ductile iron pipes in water, sewage, and gas systems. They ensure leak-proof joints and withstand high pressure. Their durability makes them ideal for municipal and industrial applications.

What advantages do ductile iron pipe fittings offer over other materials?

Q: What advantages do ductile iron pipe fittings offer over other materials?

A: They provide superior strength, corrosion resistance, and flexibility compared to traditional cast iron. Their longevity reduces maintenance costs, and they handle extreme temperatures and pressures efficiently.

What is a uni flange for ductile iron pipes?

Q: What is a uni flange for ductile iron pipes?

A: A uni flange is a modular flange adapter that connects ductile iron pipes to valves or equipment. It simplifies installations and allows easy disassembly for maintenance. Its design ensures compatibility with various pipe sizes.

How are iron pipe fittings installed securely?

Q: How are iron pipe fittings installed securely?

A: They’re installed using mechanical joints, flanges, or welding, depending on the application. Proper sealing with gaskets and bolts ensures leak resistance. Alignment checks and torque specifications are critical during installation.

Can ductile iron pipe fittings be used in corrosive environments?

Q: Can ductile iron pipe fittings be used in corrosive environments?

A: Yes, when coated with epoxy or linings like cement mortar. These coatings prevent chemical and electrochemical corrosion. Regular inspections further enhance their performance in harsh conditions.