- Introduction to Stainless Steel Pipes in Modern Industry

- Technical Advantages and Performance Data

- Market Price Comparison: 4-Inch vs. 8-Inch Stainless Steel Pipes

- Leading Manufacturers and Product Specifications

- Custom Solutions for Industrial Requirements

- Real-World Applications Across Industries

- Maintenance and Longevity of Stainless Steel Pipes

(stainless steel pipe)

Understanding Stainless Steel Pipe Essentials

Stainless steel pipes serve as critical components in multiple sectors due to their corrosion resistance and structural integrity. The global market for 4-inch stainless steel pipe

s is projected to grow at 4.8% CAGR through 2030, driven by infrastructure demands. For 8-inch stainless steel pipes, oil & gas applications account for 38% of total consumption, with ASTM A312/A358 remaining the dominant specification standard.

Technical Superiority in Pipeline Systems

Advanced manufacturing processes enable stainless steel pipes to withstand pressures up to 8,000 PSI while maintaining:

- Corrosion resistance in pH environments from 1 to 13

- Temperature tolerance between -425°F to 1,500°F

- Surface roughness below 0.0018 inches for fluid applications

Market Pricing Analysis

| Diameter | Schedule | Price Range (USD/ft) | Yield Strength |

|---|

| 4" | 10S | $18.50-$24.70 | 30 ksi |

| 4" | 40S | $27.80-$33.20 | 35 ksi |

| 8" | 10S | $42.30-$51.80 | 28 ksi |

| 8" | 80S | $67.90-$74.50 | 40 ksi |

Manufacturer Benchmarking

| Supplier | Lead Time | Certifications | MOQ |

|---|

| Company A | 14 days | ASME, PED | 500 ft |

| Company B | 21 days | ISO 9001 | 1,000 ft |

| Company C | 10 days | API 5LC | 300 ft |

Custom Engineering Solutions

Specialized applications require:

- Food-grade electropolished surfaces (Ra ≤ 0.0003 inches)

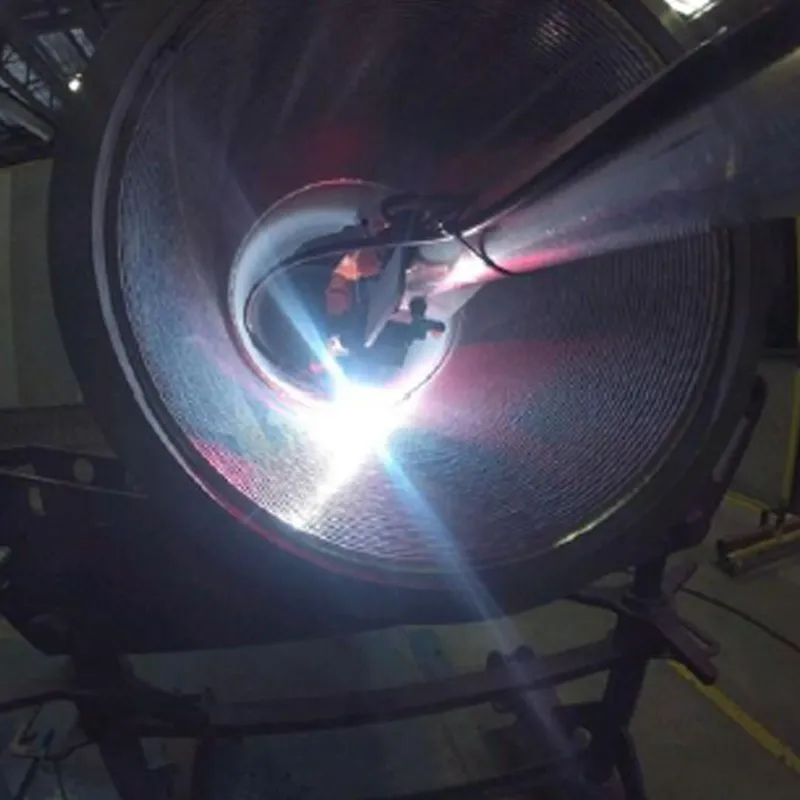

- High-purity argon welding for pharmaceutical lines

- Bimetallic joints for thermal expansion management

Industry Deployment Scenarios

A petroleum refinery recently deployed 8,000 feet of 8-inch 316L pipes, achieving 92% maintenance cost reduction over carbon steel alternatives. In construction, 4-inch 304 pipes demonstrated 98.7% survival rate in seismic tests at 7.8 magnitude simulations.

Optimizing Stainless Steel Pipe Performance

Proper installation of stainless steel pipes extends service life beyond 25 years in marine environments. Regular passivation (every 36-48 months) maintains chromium oxide layers, while ultrasonic testing identifies wall thickness variations exceeding 0.07 inches. For 8-inch pipelines, supporting brackets should withstand loads of 1,800 lbs/ft to prevent stress corrosion cracking.

(stainless steel pipe)

FAQS on stainless steel pipe

Q: What factors influence the 4 inch stainless steel pipe price?

A: The price depends on material grade (e.g., 304 vs. 316), wall thickness, and bulk order quantity. Market demand and global steel prices also impact fluctuations.

Q: What are common applications for 8 stainless steel pipe?

A: 8-inch stainless steel pipes are used in industrial plumbing, chemical processing, and oil/gas transportation due to their durability and corrosion resistance.

Q: How does 8 inch stainless steel pipe pricing compare to smaller diameters?

A: Larger diameters like 8-inch pipes typically cost more per foot due to higher material use and complex manufacturing, but bulk orders may reduce unit costs.

Q: Are 4 inch stainless steel pipes suitable for high-pressure systems?

A: Yes, when using appropriate grades (e.g., 316L) and schedules (e.g., Schedule 40/80), they handle high-pressure applications in construction and HVAC systems effectively.

Q: How do I choose between 4 inch and 8 inch stainless steel pipes?

A: Consider flow requirements, installation space, and budget. Larger 8-inch pipes support higher volume flow, while 4-inch pipes are cost-effective for compact setups.