(stainless steel pipe)

Stainless steel pipes serve as critical components in multiple sectors due to their corrosion resistance and structural integrity. The global market for 4-inch stainless steel pipe

s is projected to grow at 4.8% CAGR through 2030, driven by infrastructure demands. For 8-inch stainless steel pipes, oil & gas applications account for 38% of total consumption, with ASTM A312/A358 remaining the dominant specification standard.

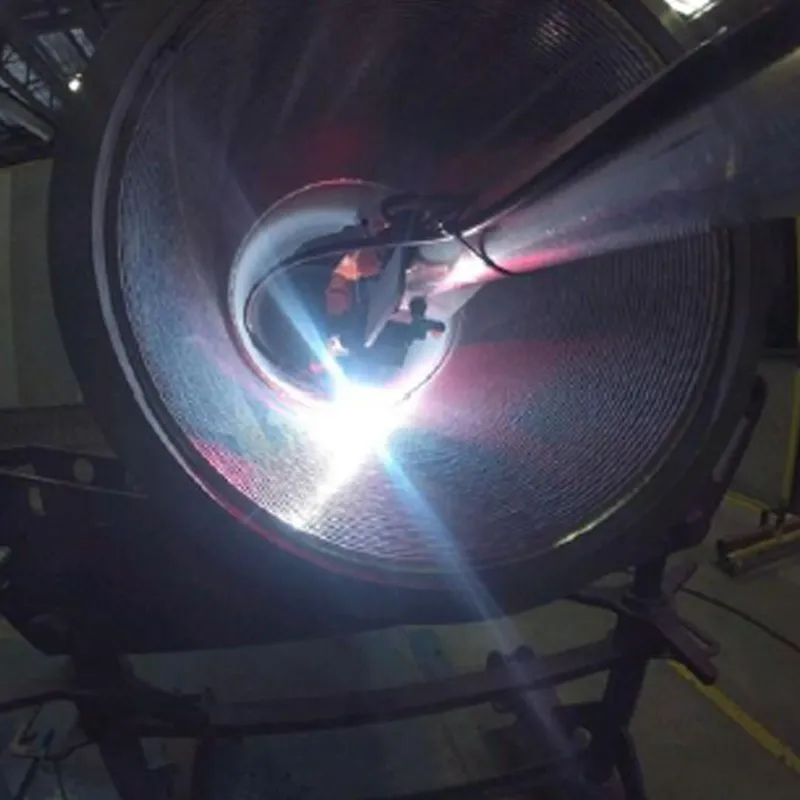

Advanced manufacturing processes enable stainless steel pipes to withstand pressures up to 8,000 PSI while maintaining:

| Diameter | Schedule | Price Range (USD/ft) | Yield Strength |

|---|---|---|---|

| 4" | 10S | $18.50-$24.70 | 30 ksi |

| 4" | 40S | $27.80-$33.20 | 35 ksi |

| 8" | 10S | $42.30-$51.80 | 28 ksi |

| 8" | 80S | $67.90-$74.50 | 40 ksi |

| Supplier | Lead Time | Certifications | MOQ |

|---|---|---|---|

| Company A | 14 days | ASME, PED | 500 ft |

| Company B | 21 days | ISO 9001 | 1,000 ft |

| Company C | 10 days | API 5LC | 300 ft |

Specialized applications require:

A petroleum refinery recently deployed 8,000 feet of 8-inch 316L pipes, achieving 92% maintenance cost reduction over carbon steel alternatives. In construction, 4-inch 304 pipes demonstrated 98.7% survival rate in seismic tests at 7.8 magnitude simulations.

Proper installation of stainless steel pipes extends service life beyond 25 years in marine environments. Regular passivation (every 36-48 months) maintains chromium oxide layers, while ultrasonic testing identifies wall thickness variations exceeding 0.07 inches. For 8-inch pipelines, supporting brackets should withstand loads of 1,800 lbs/ft to prevent stress corrosion cracking.

(stainless steel pipe)

A: The price depends on material grade (e.g., 304 vs. 316), wall thickness, and bulk order quantity. Market demand and global steel prices also impact fluctuations.

A: 8-inch stainless steel pipes are used in industrial plumbing, chemical processing, and oil/gas transportation due to their durability and corrosion resistance.

A: Larger diameters like 8-inch pipes typically cost more per foot due to higher material use and complex manufacturing, but bulk orders may reduce unit costs.

A: Yes, when using appropriate grades (e.g., 316L) and schedules (e.g., Schedule 40/80), they handle high-pressure applications in construction and HVAC systems effectively.

A: Consider flow requirements, installation space, and budget. Larger 8-inch pipes support higher volume flow, while 4-inch pipes are cost-effective for compact setups.

Korróziógátló és hőszigetelő termékek

Karbon varrat nélküli acélcsövek

Exploring the Diverse World of Flanges and Their Critical Roles

A Deep Dive into Flanges: Key Components for Connection and Sealing

In-Depth Discussion Of Flanges: Cf40, Cl150, Cs And Their Applications

The Crucial Role of Flanges in Industrial and Utility Systems

Flange Varieties in Industrial Applications: A Comprehensive Overview

Flange Solutions for Enhanced Plumbing and Fixture Installations

Exploring the Diverse World of Flanges and Their Critical Roles

A Deep Dive into Flanges: Key Components for Connection and Sealing

In-Depth Discussion Of Flanges: Cf40, Cl150, Cs And Their Applications

The Crucial Role of Flanges in Industrial and Utility Systems

Ha felkeltette érdeklődését termékeink, itt hagyhatja adatait, és hamarosan felvesszük Önnel a kapcsolatot.