Steel products have long been the backbone of numerous industries, providing strength, durability, and reliability in various applications. Among these, items related to black steel pipe for water, black steel tube, as well as the processes of buying steel pipe and buying steel tubing, and components like carbon steel elbow, play crucial roles in construction, plumbing, and industrial systems. These products are not only essential for transporting water but also for creating robust structures and facilitating the flow of fluids in diverse settings.

Black Steel Pipe for Water: A Reliable Water Conduit

When it comes to water transportation, black steel pipe for water stands out as a tried - and - true option. In residential plumbing systems, these pipes are often used to carry water from the main supply to various fixtures. Their robust construction allows them to withstand high water pressures, ensuring a consistent and reliable water flow. The black coating on the steel pipe serves as a protective layer, preventing corrosion and extending the lifespan of the pipe. This is particularly important in areas where the water may contain minerals or other substances that could otherwise cause rust and degradation over time. In commercial and industrial settings, black steel pipe for water is utilized in large - scale water distribution networks, such as those found in factories, office buildings, and municipal water systems. Their strength and durability make them capable of handling the demands of these complex systems.

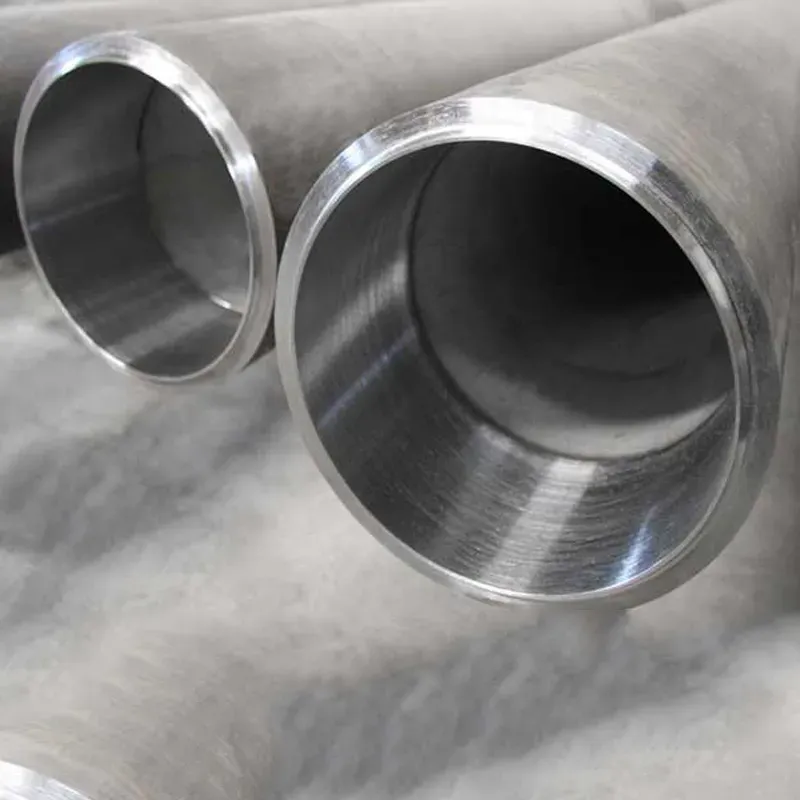

The Versatility of Black Steel Tubes

Black steel tube offers a wide range of applications beyond water transportation. In the construction industry, these tubes are used in the fabrication of structural frameworks. Their high strength - to - weight ratio makes them ideal for supporting the weight of buildings, bridges, and other structures. The black finish not only provides some level of corrosion resistance but also gives the tubes an aesthetically pleasing appearance, which can be beneficial in architectural designs where the structure is visible. Additionally, in the automotive industry, black steel tube is employed in the manufacturing of vehicle frames, roll cages, and exhaust systems. The tubes' ability to withstand mechanical stress and harsh environmental conditions makes them a preferred choice for these critical components.

Navigating the Process of Buying Steel Pipe and Tubing

The process of buying steel pipe and buying steel tubing requires careful consideration of several factors. For those in need of steel pipes or tubes, the first step is to determine the specific requirements of the project. This includes factors such as the diameter, wall thickness, length, and grade of the steel. Different projects may demand different specifications; for example, a plumbing project may require pipes with a specific inner diameter to ensure proper water flow, while a construction project may need tubes with a certain strength rating to support the structure. Once the requirements are clear, buyers can explore various suppliers. It's important to choose suppliers with a good reputation for quality and reliability. Reading customer reviews, asking for referrals, and comparing prices and product offerings from different suppliers can help in making an informed decision. Some suppliers may also offer additional services such as custom cutting and bending of the steel pipe or tubing, which can be valuable depending on the project's needs.

The Importance of Carbon Steel Elbows

Carbon steel elbow is a key component in piping systems, enabling changes in direction of the fluid flow. In water systems, these elbows are used to redirect water from one pipe to another, allowing for complex routing of the water supply. Their strength and durability ensure that they can withstand the pressure and flow of water without deforming or leaking. In industrial applications, such as in chemical processing plants or oil refineries, carbon steel elbows are subjected to high temperatures and corrosive substances. The carbon steel construction provides the necessary resistance to these harsh conditions, ensuring the integrity of the piping system. Proper installation of carbon steel elbows is crucial to maintain the efficiency and safety of the system. They must be welded or fitted correctly to prevent any potential leaks or disruptions in the flow of fluids.

FAQs about Steel Pipe and Related Products

How to Ensure the Quality of Purchased Steel Pipe and Tubing

To ensure the quality of bought steel pipe and bought steel tubing, start by checking the supplier's certifications. Reputable suppliers often have certifications from recognized organizations that verify the quality and compliance of their products. Inspect the physical appearance of the pipes or tubes for any visible defects such as dents, cracks, or uneven surfaces. Request material test reports, which can provide information about the chemical composition and mechanical properties of the steel. These reports can help confirm that the product meets the required standards for the intended application. Additionally, consider ordering samples before making a large - scale purchase to thoroughly evaluate the quality.

What Are the Different Grades of Steel Used in Pipes and Tubes?

There are several grades of steel used in steel pipe and steel tubing. Common grades include ASTM A53, which is a general - purpose steel pipe suitable for a wide range of applications, including water and gas transmission. ASTM A106 is used for high - temperature service in steam and other high - pressure fluid systems. Each grade has specific chemical and mechanical property requirements, such as yield strength, tensile strength, and chemical composition limits. The choice of grade depends on the application, environmental conditions, and the pressure and temperature the pipe or tube will be subjected to.

How to Install Carbon Steel Elbows in a Piping System?

Installing carbon steel elbows requires proper preparation and techniques. First, ensure that the pipes and elbows are clean and free of any debris or contaminants. Measure and cut the pipes to the appropriate length, leaving enough space for the elbow to be fitted. When welding the elbow to the pipes, use the correct welding procedure and equipment for carbon steel. Pre - heating the steel before welding can help prevent cracking. After welding, inspect the joint for any defects, such as porosity or incomplete fusion. Non - destructive testing methods like ultrasonic testing or X - ray inspection can be used for a more thorough assessment. If the elbow is to be connected using fittings, ensure that the fittings are properly tightened to prevent leaks.

Can Black Steel Pipe for Water Be Used for Other Fluids?

Black steel pipe for water can be used for other fluids in many cases, but it depends on the nature of the fluid. For example, it can be used for transporting certain types of gases, such as natural gas, as long as the pipe meets the relevant safety and regulatory requirements. However, for corrosive fluids, additional precautions may be needed. Some chemicals can react with the steel and cause corrosion, reducing the lifespan of the pipe. In such cases, it may be necessary to use pipes with special coatings or made from different materials. Always consult with experts or refer to industry standards when considering using black steel pipe for non - water fluids.

What Factors Affect the Price of Buying Steel Pipe and Tubing?

The price of buying steel pipe and buying steel tubing is influenced by multiple factors. The cost of raw materials, such as iron ore and scrap steel, has a significant impact on the price. Fluctuations in the global market for these raw materials can cause price variations. The manufacturing process also plays a role; more complex manufacturing techniques or higher - quality production standards may increase the cost. Additionally, the size and specifications of the pipe or tube, such as diameter, wall thickness, and length, can affect the price. Larger - diameter or thicker - walled pipes generally cost more. The quantity ordered can also result in price discounts, with bulk purchases often being more cost - effective. Finally, transportation costs and the location of the supplier can contribute to the overall price paid by the buyer.