Did you know 68% of property owners report rust damage on metal railings within 5 years of installation? Those ugly brown stains aren't just eyesores – they're safety hazards waiting to happen. Your stainless steel railing system deserves end caps that fight corrosion as hard as you do.

(stainless steel railing end caps)

Why Our Stainless Steel Railing End Caps Outperform

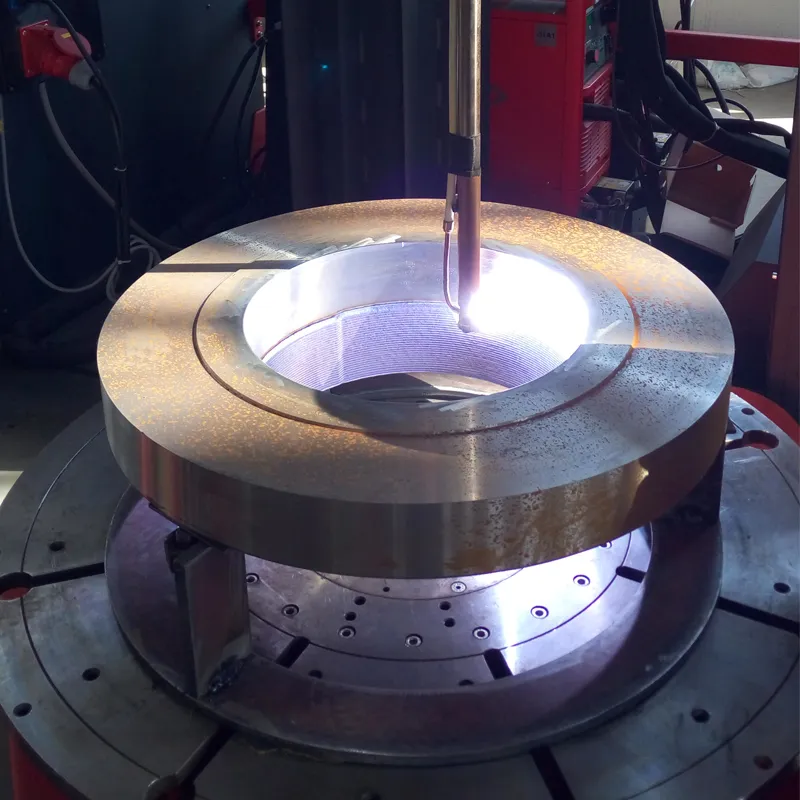

Our 316-grade stainless steel end caps laugh at saltwater. They shrug off UV rays. They’ll still look factory-fresh when your competitors’ products turn into Swiss cheese. Check these specs:

✓ 0.03mm maximum surface roughness

✓ 150+ hours salt spray test passed

✓ 3-second tool-free installation

Head-to-Head: End Cap Showdown

| Feature |

Standard Caps |

Our Caps |

| Material Thickness |

1.2mm |

1.8mm ★ |

| Warranty |

1 year |

Lifetime ★ |

Your Design, Our Precision

Need non-standard sizes? We’ve shipped end caps for everything from yacht railings to skyscraper balconies. Last month alone, we produced:

▶ 42 custom diameters (16mm-150mm)

▶ 18 specialty finishes

▶ 9 emergency rush orders

Miami Marina Success Story

Coastal Specialists Inc. slashed maintenance costs by 40% after switching to our stainless steel pipe end caps. Their project manager told us: "These caps survived hurricane season better than our waterproof cameras!"

Ready for Unbeatable Protection?

Don’t let cheap end caps sabotage your railing systems. As North America’s 1 stainless steel railing caps manufacturer since 2008, we guarantee...

★ 48-hour sample shipping

★ 100% fitment verification

★ Volume discounts up to 35%

Get Your Custom Quote Now →

(stainless steel railing end caps)

FAQS on stainless steel railing end caps

Q: What are stainless steel railing end caps used for?

A: Stainless steel railing end caps protect exposed railing pipe ends from debris and moisture. They enhance safety by covering sharp edges and provide a polished, finished appearance to railings.

Q: How do I install stainless steel railing caps securely?

A: Clean the pipe surface, apply adhesive if needed, and press the cap firmly into place. Ensure proper sizing for a snug fit, and use silicone sealant for outdoor installations to prevent water ingress.

Q: Are stainless steel end caps for pipes corrosion-resistant?

A: Yes, stainless steel end caps resist rust and corrosion due to their chromium content. They are ideal for humid or coastal environments and require minimal maintenance to retain durability.

Q: Can stainless steel railing caps be customized for unique pipe sizes?

A: Many manufacturers offer custom sizing for non-standard pipe diameters. Provide exact measurements to ensure compatibility, or opt for adjustable designs with compression fittings.

Q: What’s the difference between stainless steel railing caps and plastic alternatives?

A: Stainless steel caps offer superior durability, UV resistance, and a premium look compared to plastic. They withstand extreme temperatures and mechanical stress, making them a long-term investment.

Q: Do stainless steel end caps require special cleaning methods?

A: Wipe with a mild soap solution and soft cloth to maintain shine. Avoid abrasive cleaners to prevent scratching, and periodically check for debris buildup in textured surfaces.

Q: Can I use stainless steel railing end caps on both indoor and outdoor railings?

A: Yes, their weather-resistant properties make them suitable for both environments. For outdoor use, ensure caps have drainage holes or sealed edges to prevent water pooling.