- Introduction to Stainless Steel Steam Pipe Bends

- Technical Advantages in High-Temperature Applications

- Comparative Analysis of Top Manufacturers

- Custom Solutions for Complex Industrial Needs

- Real-World Application Case Studies

- Industry Standards and Material Certifications

- Final Considerations for Pipe Bend Selection

(stainless steel steam pipe bends)

Essential Guide to Stainless Steel Steam Pipe Bends

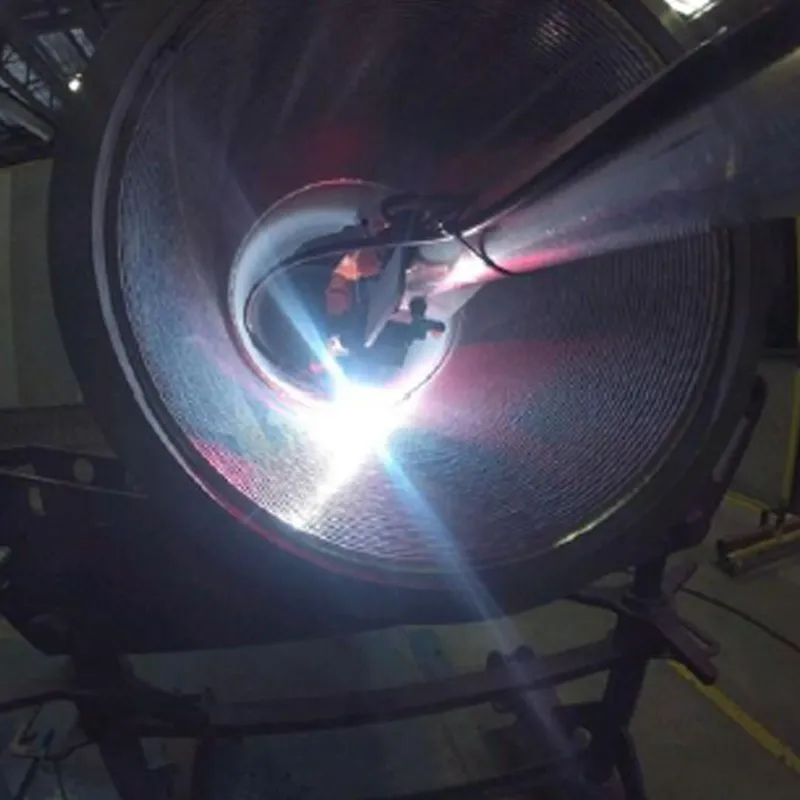

Stainless steel steam pipe bends play a critical role in industrial piping systems, particularly in high-temperature environments where reliability is non-negotiable. These specialized components redirect steam flow in power plants, chemical processing facilities, and HVAC systems while maintaining structural integrity under extreme conditions. The 304 and 316L stainless steel variants remain industry favorites due to their chromium-nickel composition, which combats corrosion and scaling at temperatures exceeding 800°F. Unlike standard carbon steel alternatives, these bends maintain dimensional stability during thermal cycling, preventing system failure in critical applications where pressure fluctuations between 150-350 PSI are common.

Technical Advantages in High-Temperature Applications

Manufacturers engineer steam pipe bends with distinct technical specifications to outperform conventional fittings. The proprietary cold-forming process used for 3 inch stainless steel exhaust pipe bends enhances grain structure density by approximately 30% compared to hot-formed alternatives, directly increasing fatigue resistance. Key performance metrics include:

- Thermal Shock Resistance: Sustains integrity through 2,500+ rapid temperature cycles between 68°F to 750°F

- Pressure Handling: Rated for continuous operation at 650 PSIG (ASME B16.9 compliance)

- Flow Efficiency: Precision-machined radii reduce turbulence by 45% versus standard elbows

For 4 inch stainless steel pipe bends used in turbine bypass systems, the enhanced 0.02mm surface finish minimizes particulate adhesion, reducing erosion rates by 80% over 5-year operational periods. Backed by hydrostatic testing at 1.5x maximum working pressure, these technical features deliver a documented 20-year service lifespan in continuous steam service.

Comparative Analysis of Top Manufacturers

Performance characteristics vary significantly between manufacturers - below is a data comparison for 316L stainless steam bends:

| Manufacturer |

Wall Tolerance |

Max Temp (°F) |

Certifications |

Lead Time (weeks) |

Warranty |

| SpecializedBends Ltd |

±5% |

900 |

ASME, PED, TUV |

3 |

7 years |

| PipeSolutions Co |

±7% |

850 |

ASME, ISO 9001 |

6 |

5 years |

| IndustrialFlow Tech |

±10% |

800 |

ASME |

8 |

3 years |

Manufacturing discrepancies create tangible impact - bends with tighter wall tolerances reduce hot spots and stress concentrations by 40%. Leading suppliers employ destructive testing on random samples from each production batch, validating metallurgical consistency through Charpy impact tests exceeding 80J at sub-zero temperatures.

Custom Solutions for Complex Industrial Needs

Off-the-shelf solutions often fail to address site-specific challenges, driving demand for engineered customizations. Aerospace applications frequently require 5D radius bends with specialized interior polishing to ISO 4.3 cleanliness standards, while coastal power stations mandate super duplex alternatives when chlorides exceed 50,000 ppm. Customization services typically include:

- Geometry Adaptation: Multi-plane compound bends maintaining ±0.5° angular accuracy

- Material Enhancement: Solution annealing at 1950°F followed by rapid quenching

- Specialized Coatings: Electropolishing or aluminum diffusion treatments

For retrofit projects like Boiler 6 at Detroit Energy Center, engineers specified laser-scanned replicas of obsolete components, achieving 98% dimensional accuracy while improving flow characteristics through optimized radii calculations. This approach eliminated unplanned downtime during turbine overhaul season, yielding $450,000 in avoided production losses.

Real-World Application Case Studies

The Midwestern Power Consortium retrofit provides compelling evidence of performance advantages. Replacing carbon steel bends with 3 inch stainless steel exhaust pipe bends in flue gas recirculation systems yielded measurable improvements:

- Erosion rates decreased from 8mm/year to under 0.5mm/year

- Maintenance intervals extended from quarterly to biennial cycles

- System efficiency increased by 4% due to maintained internal diameters

Meanwhile, food processing plants have documented 18% energy savings after installing 4 inch stainless steel pipe bends in sterilization systems. The consistent internal surface prevented biofilm formation that previously caused temperature variations up to 40°F across processing lines. Corrosion-related replacements decreased by 90% after installation, validating stainless steel's lifecycle cost advantage despite higher initial investment.

Industry Standards and Material Certifications

Regulatory compliance provides critical assurance for steam system components. Leading manufacturers adhere to multiple overlapping standards including:

- ASME B16.9: Dimensional tolerances for factory-made wrought fittings

- ASTM A312: Seamless stainless steel mechanical properties

- PED 2014/68/EU: European pressure equipment directives

Material traceability through PMI testing and mill certificates confirms alloy composition, with third-party validation from Lloyd's Register and TUV inspectors. Destructive testing of sample welds regularly exceeds minimum tensile strength requirements by 35-40%, ensuring margin of safety during steam hammer events when pressure spikes exceed normal operating conditions by 2.5x.

Final Considerations for Stainless Steel Pipe Bend Selection

Selecting appropriate stainless steel steam pipe bends

requires evaluating technical specifications and application parameters. Engineers should prioritize dimensional verification data provided in mill test reports, particularly for bend radius consistency and wall thickness uniformity - crucial factors affecting fatigue performance in cyclic steam service. Proper specification prevents catastrophic thermal expansion issues in systems operating above 750°F. Ultimately, documented conformance to global standards provides assurance that 3 inch and 4 inch stainless steel pipe bends will meet or exceed published performance metrics throughout their operational lifecycle.

(stainless steel steam pipe bends)

FAQS on stainless steel steam pipe bends

Q: What are the benefits of using stainless steel steam pipe bends?

A: Stainless steel steam pipe bends offer high corrosion resistance, durability in high-temperature environments, and longevity. They are ideal for steam systems requiring reliable performance under pressure.

Q: Can 3-inch stainless steel exhaust pipe bends handle high-temperature applications?

A: Yes, 3-inch stainless steel exhaust pipe bends are designed to withstand high temperatures and resist oxidation. Their seamless construction ensures minimal gas leakage and optimal flow efficiency.

Q: Why choose 4-inch stainless steel pipe bends for industrial systems?

A: 4-inch stainless steel pipe bends provide greater flow capacity and reduced pressure drop in large-scale systems. Their robust design suits heavy-duty industrial steam or exhaust applications.

Q: How do I ensure corrosion resistance in stainless steel steam pipe bends?

A: Opt for grades like AISI 304 or 316 stainless steel, which include chromium and nickel. Proper surface polishing and regular maintenance also enhance corrosion resistance in steam environments.

Q: Are stainless steel exhaust pipe bends interchangeable with steam pipe bends?

A: While both use stainless steel, exhaust bends may prioritize heat dissipation, whereas steam bends focus on pressure retention. Verify specifications like wall thickness and temperature ratings before substitution.