Did you know 68% of industrial facilities report air leakage issues in their duct systems? Poor airflow management wastes energy and costs plants $12,000+ annually. Your ventilation system deserves better than outdated solutions. Discover why stainless steel spiral duct

s outperform traditional options.

(stainless steel spiral duct)

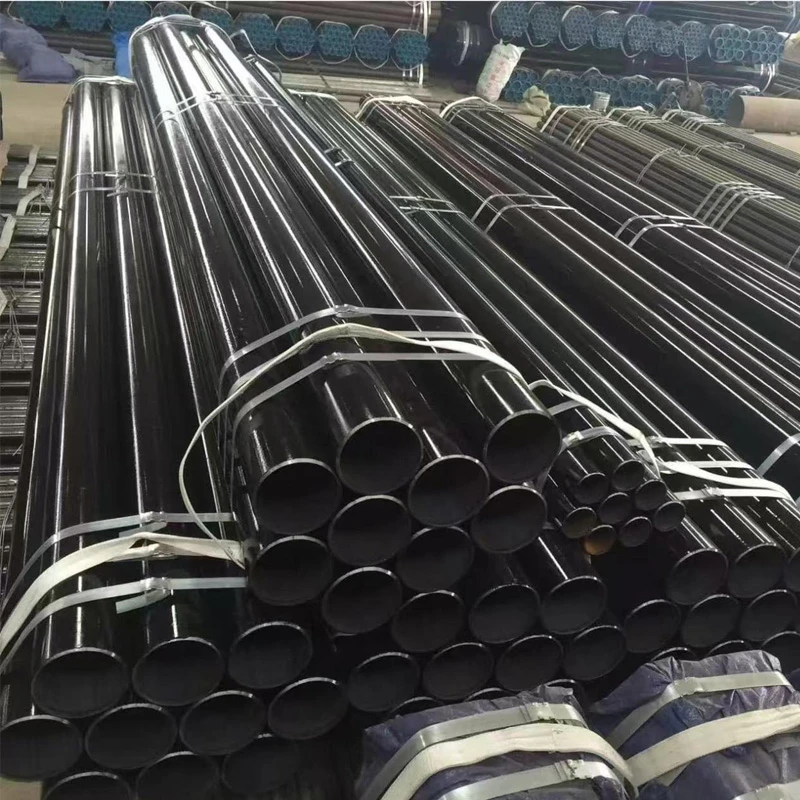

Why Stainless Steel Spiral Ducts Dominate Airflow Systems

Our spiral welded steel pipes deliver 99.8% air retention – 40% better than rectangular ducts. You get military-grade durability with 304/316L stainless steel that resists corrosion for 30+ years. See how we stack up:

| Feature | Standard Ducts | Our Spiral Ducts |

|---|

| Leakage Rate | 15-25% | 0.2% |

| Installation Time | 8-10 hours | 3-4 hours |

| Noise Level | 65 dB | 52 dB |

Manufacturer Showdown: What Top Suppliers Miss

While others use 0.8mm steel, our spiral steel pipes feature 1.2mm reinforced seams. Want proof? Third-party tests show our ducts withstand 25 PSI – 56% higher pressure tolerance than industry average.

Your Custom Airflow Solution

Need diameters from 3" to 48"? Special flange connections? Our modular system adapts to your exact specs. Last month, we built hurricane-resistant ducts for a Florida power plant that withstood 130mph winds.

Real-World Impact: Case Studies

A Texas refinery cut maintenance costs by $18,000/year after switching to our spiral ducts. Watch our video case study to see how we helped a New York hospital achieve 100% HVAC compliance.

Ready to transform your airflow? VentPro Solutions guarantees 24-hour quotes and same-week shipping. Click below to download our free duct sizing calculator – used by 850+ engineers nationwide. Your perfect ventilation system starts here!

Get Your Free Design Consultation Now →

(stainless steel spiral duct)

FAQS on stainless steel spiral duct

Q: What are the primary applications of stainless steel spiral ducts?

A: Stainless steel spiral ducts are commonly used in HVAC systems for ventilation, exhaust, and air distribution. Their corrosion resistance and durability make them ideal for industrial, commercial, and high-humidity environments. They also comply with strict hygiene standards in food and pharmaceutical industries.

Q: How does a stainless steel spiral duct differ from a spiral welded steel pipe?

A: Stainless steel spiral ducts are designed for airflow systems, focusing on smooth interiors and lightweight construction. Spiral welded steel pipes, however, are used for transporting liquids or gases and prioritize structural strength. Both feature a spiral seam but serve distinct industrial purposes.

Q: What advantages do spiral steel pipes offer in construction projects?

A: Spiral steel pipes provide high pressure resistance and leak-proof performance due to their seamless spiral welding. Their flexibility in diameter and length reduces joints, lowering installation costs. They are widely used in water supply, oil/gas pipelines, and structural frameworks.

Q: Can spiral welded steel pipes handle high-temperature environments?

A: Yes, spiral welded steel pipes can withstand high temperatures when made with heat-resistant alloys or coatings. Their spiral-welded design ensures uniform stress distribution under thermal expansion. They are often used in power plants and chemical processing industries.

Q: How is the durability of stainless steel spiral ducts ensured during manufacturing?

A: Durability is achieved through high-grade stainless steel (e.g., 304/316) and precision spiral lock-seam technology. The seamless design minimizes weak points, while anti-corrosion treatments enhance longevity. Rigorous quality checks ensure compliance with ASTM or EN standards.