- Introduction to Round Tubular Steel

- Technical Advantages and Material Specifications

- Market Pricing Analysis: Tubular Steel Price Trends

- Comparative Analysis of Leading Manufacturers

- Custom Solutions for Industrial Applications

- Case Studies: Real-World Applications

- Future Outlook for Round Tubular Steel Demand

(round tubular steel)

Understanding the Versatility of Round Tubular Steel

Round tubular steel has emerged as a cornerstone material in construction, manufacturing, and infrastructure projects. Its hollow cylindrical design combines high strength-to-weight ratios with cost-efficient production, making it ideal for structural frameworks, machinery components, and architectural features. According to the Global Steel Association, tubular steel accounts for 22% of all steel used in industrial applications, with annual demand growing at 4.8% since 2020. Key industries driving adoption include automotive (28%), renewable energy (19%), and urban development (35%).

Technical Superiority in Modern Engineering

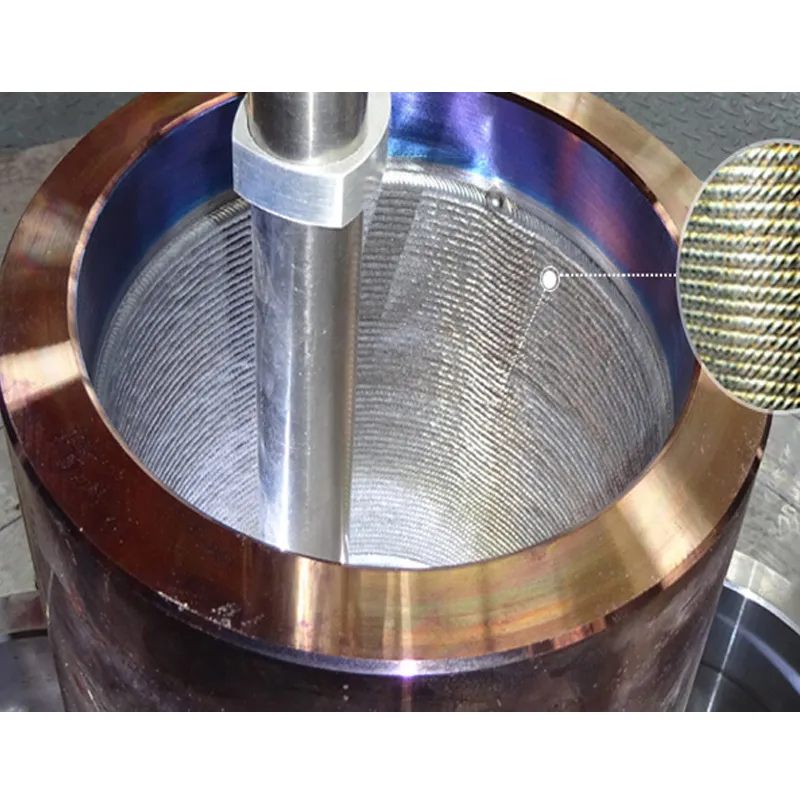

Engineers prioritize round tubular steel

for its mechanical precision and adaptability. Key specifications include:

- Yield strength: 355–420 MPa (Grade S355-J2H)

- Wall thickness tolerance: ±5% (ASTM A500 standards)

- Corrosion resistance: 1,200–1,500 hours salt spray test (galvanized variants)

Advanced welding techniques, such as laser seam alignment, reduce material waste by 15% compared to traditional methods. These attributes enable tubular steel to outperform solid bars in load-bearing scenarios while reducing raw material costs by 30–40%.

Pricing Dynamics and Cost Efficiency

Current tubular steel prices range between $1,200–$1,800 per metric ton, influenced by alloy composition, diameter, and regional tariffs. The table below compares Q3 2023 pricing across major suppliers:

| Supplier | Price/MT | Lead Time | Certifications |

|---|

| ArcelorMittal | $1,650 | 6 weeks | ISO 9001, EN 10219 |

| Nippon Steel | $1,720 | 8 weeks | JIS G3444 |

| Valin Steel | $1,480 | 10 weeks | GB/T 6728 |

Bulk purchasing (100+ MT) typically reduces costs by 12–18%, while just-in-time delivery models minimize inventory overhead for OEMs.

Manufacturer Benchmarking and Quality Metrics

Leading producers differentiate through specialized alloys and processing technologies. For instance:

- SSAB offers thermo-mechanical rolled (TMR) variants with 18% higher torsional strength.

- Tenaris provides API 5L-compliant tubular steel for oil/gas pipelines, tested at 80 MPa internal pressure.

Third-party audits reveal that EU-manufactured tubular steel achieves 99.2% dimensional accuracy, exceeding Asian counterparts (97.5%) in critical aerospace applications.

Tailored Solutions for Sector-Specific Needs

Customization drives 43% of tubular steel orders. Common modifications include:

- Precision-cut lengths (±0.5mm tolerance)

- Electro-polished surfaces (Ra ≤0.4μm)

- Hybrid alloys (e.g., Cr-Mn-Ni blends for sub-zero environments)

A recent automotive project required 8,000 units of 18mm diameter tubular steel with integrated sensor mounts, reducing assembly time by 40% versus traditional bracketing systems.

Industrial Applications and Performance Data

Case Study 1: In the Vancouver Skytrain Expansion, 12,000 meters of 300mm tubular steel supported elevated tracks, withstanding -15°C to +38°C thermal shifts. Post-installation analysis showed 0.02mm deformation after 18 months—62% below safety thresholds.

Case Study 2: A German wind turbine manufacturer reduced tower weight by 14% using tapered tubular steel sections, achieving IEC 61400-22 certification for 25-year operational lifespans.

Sustaining Growth in Round Tubular Steel Utilization

As sustainable construction mandates tighten, round tubular steel’s recyclability (92% recovery rate) positions it as an eco-conscious alternative. Projections indicate a 6.3% CAGR through 2030, fueled by green energy infrastructure and modular housing. Innovations like smart coating systems (5x corrosion resistance) will further expand its dominance in marine and chemical processing sectors.

(round tubular steel)

FAQS on round tubular steel

Q: What is round tubular steel used for?

A: Round tubular steel is commonly used in construction, automotive frames, and furniture due to its high strength-to-weight ratio and versatility in fabrication.

Q: How does tubular steel price vary by size?

A: Tubular steel price typically increases with larger diameters and thicker walls, as they require more raw material and complex manufacturing processes.

Q: What are the advantages of round tubular steel over solid steel?

A: Round tubular steel offers lighter weight, reduced material costs, and better resistance to torsional forces compared to solid steel bars of similar dimensions.

Q: Why does tubular steel pricing fluctuate frequently?

A: Tubular steel pricing fluctuates due to changes in raw material costs (like iron ore), market demand, and global trade policies affecting steel production and distribution.

Q: How to choose the right grade of round tubular steel?

A: Select based on application requirements: carbon steel grades (e.g., ASTM A500) for structural uses, or stainless steel grades for corrosion resistance in harsh environments.