In an era defined by efficiency, sustainability, and resilience, the infrastructure supporting critical industries demands materials that transcend traditional limitations. This is where the innovation of composite pipe truly shines. More than just a conduit, it represents a sophisticated engineering solution, designed to navigate the most challenging environments while delivering unparalleled performance and longevity. From deep-sea oil fields to urban water treatment facilities, the composite pipe, particularly the advanced Mechanical Clad Steel Pipe, is reshaping expectations for pipeline integrity and operational economics.

Industry Trends & Market Dynamics: Driving the Demand for Composite Pipe

The global industrial landscape is undergoing a profound transformation. Escalating demands for energy, the push for sustainable practices, and the relentless pursuit of operational efficiency are forcing industries to rethink their foundational infrastructure. Traditional steel pipes, while robust, often fall short when confronted with increasingly aggressive media, extreme temperatures, and pressures, or the imperative for decades-long service lives without costly interventions. This inadequacy has fueled a significant surge in demand for specialized piping solutions, positioning the composite pipe as a crucial answer.

Current market analyses highlight a compelling growth trajectory for clad and lined piping. Reports from sources like Grand View Research and MarketsandMarkets project the global clad pipe market to grow at a Compound Annual Growth Rate (CAGR) of over 5% from 2023 to 2030, reaching multi-billion dollar valuations. This growth is predominantly driven by heightened activity in the oil and gas sector (especially sour service and deep-water applications), chemical processing, and critical infrastructure projects globally. As a leading steel pipe manufacturer, we observe firsthand the shift from conventional pipes to advanced composite pipe solutions, reflecting an industry-wide commitment to greater asset integrity, reduced total cost of ownership (TCO), and enhanced safety standards.

The imperative for longevity in infrastructure, coupled with the rising costs of maintenance and downtime associated with corrosion-related failures, makes the superior corrosion resistance and mechanical strength of composite pipe indispensable. Furthermore, environmental regulations are becoming stricter, mandating leak-proof and durable piping systems to prevent ecological damage, further amplifying the appeal of these high-performance materials.

Mechanical Clad Steel Pipe: A Deep Dive into Technology and Performance

At the forefront of advanced piping technology stands the Mechanical Clad Steel Pipe. This isn't merely two pipes nested together; it's a meticulously engineered bimetallic solution combining the best attributes of two distinct materials: the structural strength and pressure containment capabilities of a conventional base pipe (typically carbon steel or low-alloy steel) and the exceptional corrosion resistance of an inner liner (a high-grade Corrosion Resistant Alloy, or CRA). The magic lies in the robust mechanical bond that unites these layers, ensuring integrity under extreme operational stress.

Structure and Materials: The Synergy of Strength and Resistance

- Outer Layer (Base Pipe): Commonly manufactured from carbon steels (e.g., API 5L Grade B, X42, X52, X65, X70, X80) or low-alloy steels (e.g., ASTM A335 P11/P22/P91), this layer provides the primary mechanical strength. It is designed to withstand the operational pressure, external loads, and environmental stresses. As a dedicated steel pipe manufacturer, we ensure these base pipes meet rigorous international specifications for tensile strength, yield strength, and toughness.

- Inner Layer (Liner Pipe): This critical layer is composed of CRAs chosen for their specific resistance to the media being transported. Common liner materials include:

- Stainless Steels: 304/304L, 316/316L, 317L for general corrosion and some acidic environments.

- Duplex Stainless Steels: 2205, 2507 (Super Duplex) for superior resistance to pitting, crevice corrosion, and stress corrosion cracking in chloride-rich environments, often found in seawater or sour gas applications.

- Nickel Alloys: Inconel 625, Hastelloy C-276, Incoloy 825 for extreme corrosive conditions involving highly aggressive acids, high temperatures, and severe sour service.

- Titanium: For applications requiring exceptional resistance to oxidizing acids and chlorides.

- Mechanical Bond: Unlike metallurgically bonded clad pipes which rely on explosive bonding or hot rolling, mechanical clad pipes utilize a precise mechanical expansion process. This creates an interference fit between the outer steel pipe and the inner CRA liner, ensuring excellent thermal conductivity, preventing buckling of the liner, and maintaining a robust connection even under significant thermal cycling or pressure fluctuations. This robust bond is critical for the long-term integrity of the composite pipe.

Key Technical Parameters of Composite Pipe (Mechanical Clad Steel Pipe)

Understanding the specifications is crucial for engineering and procurement decisions. The following table provides typical parameters, though custom dimensions are often available from a specialized steel pipe manufacturer.

| Parameter |

Typical Range/Description |

Notes |

| Outer Diameter (OD) |

6 inches (150 mm) to 48 inches (1200 mm) |

Larger diameters up to 60 inches or more are possible for specific projects. |

| Wall Thickness (WT) |

0.25 inches (6.35 mm) to 2 inches (50.8 mm) |

Determined by pressure rating and structural requirements of the base pipe. |

| Liner Thickness |

0.08 inches (2 mm) to 0.16 inches (4 mm) |

Optimized for corrosion protection; thicker liners offer more corrosion allowance. |

| Base Pipe Materials |

API 5L Gr. B, X42-X80; ASTM A106 Gr. B; ASTM A335 P11/P22 |

Carbon steel, low-alloy steel grades for strength. |

| Liner Materials (CRA) |

316L, 2205, 2507, Inconel 625, Hastelloy C-276, Incoloy 825, Titanium |

Chosen based on corrosive media and operating temperature. |

| Pressure Rating |

Up to 15,000 PSI (103 MPa) and beyond |

Dependent on OD, WT, and base material strength. Designed for high-pressure applications. |

| Temperature Rating |

-40°C to +350°C (or higher with specific alloys) |

Operating temperature limits influenced by both base and liner materials. |

| Applicable Standards |

API 5L, ASTM A264, ASTM A263, ASTM A265, ASME B31.3, B31.4, B31.8, NACE MR0175/ISO 15156 |

Ensures compliance with industry safety and performance requirements. |

Manufacturing Process: The Art and Science of Composite Pipe Production

The production of Mechanical Clad Steel Pipe is a complex, multi-stage process demanding precision engineering and stringent quality control. Here’s a detailed breakdown of the typical workflow, which allows a proficient steel pipe manufacturer to deliver superior composite pipe products:

- Raw Material Preparation:

- Base Pipe Selection: High-quality seamless or welded carbon steel/low-alloy steel pipes are carefully selected based on project specifications, ensuring precise dimensions and mechanical properties.

- Liner Pipe Selection: CRA seamless pipes are chosen, verified for chemical composition, wall thickness, and surface finish.

- Cutting and Beveling: Both base and liner pipes are cut to precise lengths and their ends are prepared (e.g., beveled) for subsequent processing and eventual field welding.

- Cleaning and Surface Treatment:

- The internal surface of the base pipe and the external surface of the liner pipe are thoroughly cleaned to remove rust, scale, grease, and other contaminants. This typically involves pickling, sandblasting, or high-pressure water jetting, followed by drying, to ensure optimal conditions for the mechanical bonding process.

- Assembly/Insertion:

- The cleaned CRA liner pipe is inserted into the larger diameter base pipe. This is a critical step requiring careful alignment and often specialized equipment.

- Bonding Mechanism (Hydraulic Expansion/Mechanical Drawing):

- This is the core of mechanical cladding. The most common method involves hydraulic expansion: a high-pressure fluid (typically water) is introduced into the annulus between the base pipe and liner. The immense pressure expands the inner liner outwards, pressing it tightly against the inner wall of the base pipe, creating a strong, permanent interference fit.

- Alternative methods may include mechanical drawing (pulling the liner through a die within the base pipe) or thermal shrinkage (heating the outer pipe, inserting a cooled liner, and allowing the outer pipe to shrink onto the liner upon cooling). Each method aims to achieve a full, uniform contact and bond.

- End Preparation & Sealing:

- After bonding, the pipe ends are typically machined to create a clean, uniform surface. The ends of the clad pipe are then usually sealed (e.g., by welding the liner to the base pipe at the ends, or using special end-caps) to prevent crevice corrosion between the two layers during storage, transportation, and installation. This crucial step ensures the integrity of the corrosion-resistant barrier.

- Heat Treatment (Optional but Recommended):

- Depending on the materials and specific applications, the composite pipe may undergo post-bonding heat treatment (e.g., stress relieving) to reduce residual stresses induced during the bonding process and optimize the mechanical properties of both layers.

- Quality Control & Inspection:

- This is an extensive and crucial phase, ensuring the integrity and performance of the finished composite pipe.

- Hydrostatic Testing: Each pipe is subjected to internal pressure significantly higher than its design pressure to verify structural integrity and leak-tightness.

- Non-Destructive Testing (NDT): Techniques like ultrasonic testing (UT) are employed to verify the completeness of the mechanical bond along the entire length of the pipe. Eddy current testing can check for surface imperfections.

- Shear Testing: Samples are taken from production batches and subjected to shear tests to quantify the bond strength between the liner and the base pipe.

- Dimensional Inspection: Strict checks on OD, WT, length, straightness, and end bevels.

- Visual Inspection: Thorough examination of internal and external surfaces for defects.

- Material Verification: Positive Material Identification (PMI) using X-ray fluorescence (XRF) or optical emission spectroscopy (OES) ensures the correct chemical composition of both layers.

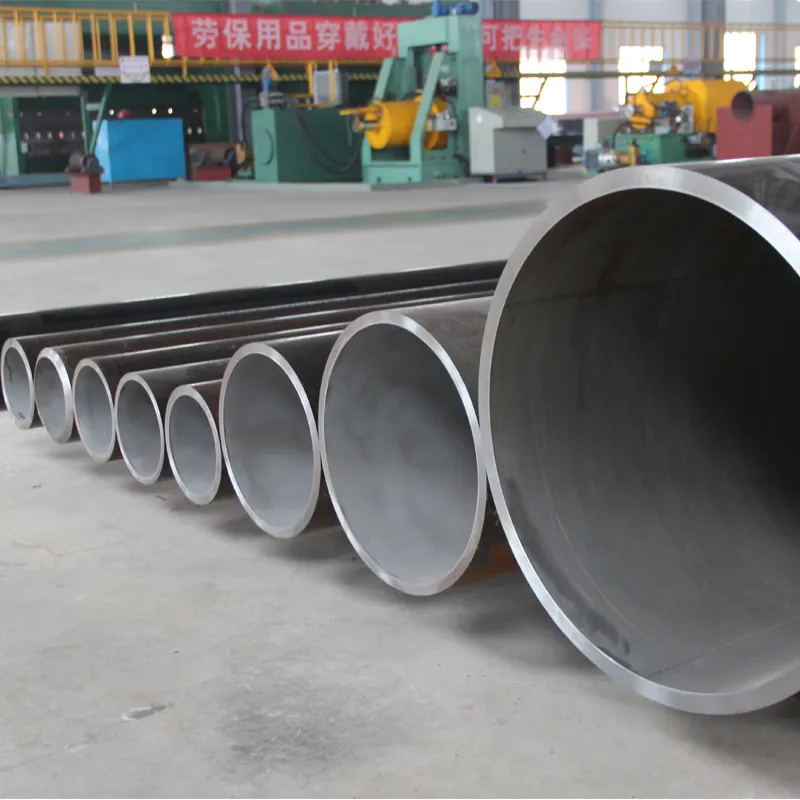

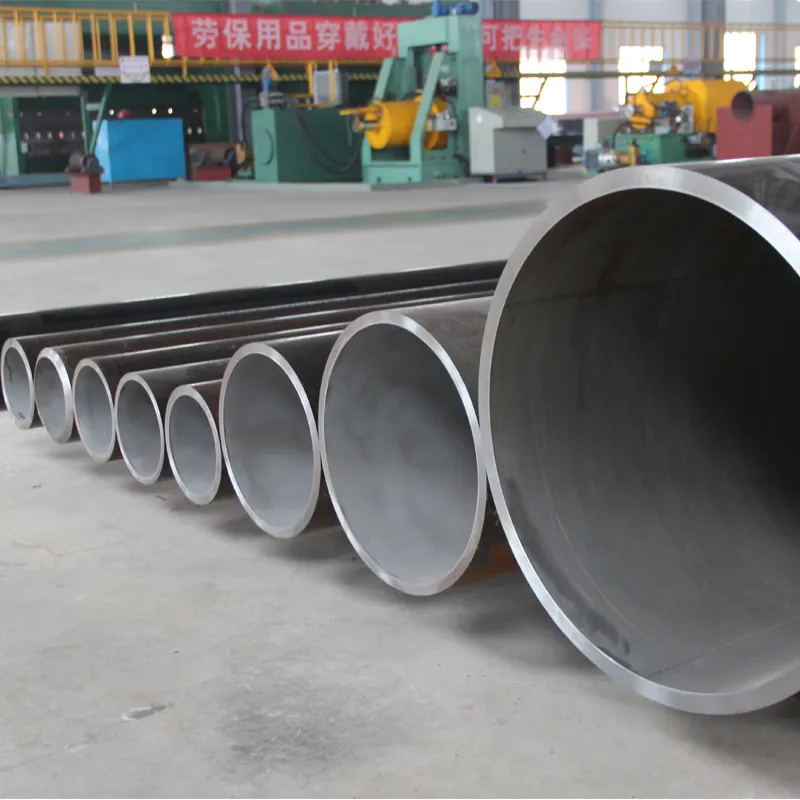

Figure 1: Depiction of a critical stage in the composite pipe manufacturing process, emphasizing precision and scale.

Unrivaled Technical Advantages of Composite Pipe

The strategic combination of materials in a composite pipe bestows it with a compelling suite of advantages that address many of the limitations of traditional piping systems. These benefits translate directly into long-term operational savings, enhanced safety, and greater environmental stewardship.

- Superior Corrosion Resistance with Cost Efficiency: The primary advantage is the inner CRA liner, which provides immunity to corrosive media that would rapidly degrade carbon steel. Unlike solid CRA pipes, which are prohibitively expensive, the composite pipe offers targeted corrosion resistance only where it's needed – on the wetted surface. This significantly reduces material costs, making high-performance solutions economically viable for large-scale projects. For example, a 16-inch, 2507 Super Duplex composite pipe can be 30-50% less expensive than a solid 2507 Super Duplex pipe, while offering comparable corrosion performance in specific applications.

- High Mechanical Strength and Pressure Rating: The carbon or low-alloy steel outer layer provides robust structural integrity, allowing the composite pipe to withstand high internal pressures and external loads. This dual functionality means engineers don't have to compromise between strength and corrosion resistance. They can design systems for extreme pressures common in upstream oil & gas or high-pressure chemical processes, confident in the pipe's mechanical reliability.

- Extended Service Life and Reduced Maintenance: By virtually eliminating internal corrosion, composite pipe dramatically extends the operational lifespan of pipelines, often exceeding 30-50 years in challenging environments. This longevity translates into significantly reduced maintenance requirements, fewer shutdowns for repair or replacement, and lower overall operational expenditures (OpEx). Data from the American Petroleum Institute (API) suggests that corrosion-related failures account for a substantial percentage of pipeline incidents, making prevention through solutions like composite pipe a key industry objective.

- Enhanced Safety and Environmental Protection: The inherent durability and corrosion resistance of composite pipe minimize the risk of leaks and ruptures, which could lead to hazardous material spills or environmental contamination. This makes them a safer choice for transporting volatile chemicals, sour gas, or pollutants, aligning with increasingly stringent environmental regulations and corporate responsibility goals.

- Versatility in Application: The ability to combine various base and liner materials means that composite pipe can be customized for a vast array of media and operating conditions. Whether it's high-temperature acidic solutions, erosive slurries, or high-pressure corrosive gases, there's a composite pipe configuration that can meet the challenge. This adaptability provides engineers with greater flexibility in material selection.

- Economic Benefits (Lower Total Cost of Ownership): While the initial capital expenditure (CapEx) for composite pipe might be higher than that for plain carbon steel, the long-term savings are substantial. Reduced material costs compared to solid alloys, minimal maintenance, extended operational life, and avoidance of costly downtime due to failures contribute to a significantly lower Total Cost of Ownership (TCO) over the project's lifecycle. A lifecycle cost analysis often reveals that the investment in a high-quality composite pipe pays for itself many times over.

Applications Across Industries: Where Composite Pipe Excels

The unique advantages of composite pipe have made it an indispensable component across a multitude of heavy industries, where operational integrity, safety, and cost-effectiveness are paramount. As a specialized steel pipe manufacturer, we have deployed Mechanical Clad Steel Pipe in some of the most demanding environments globally.

Petrochemical and Oil & Gas

This sector is arguably the largest consumer of composite pipe. Upstream, midstream, and downstream operations frequently encounter highly corrosive media such as sour gas (containing H2S and CO2), chloride-rich brines, and high-temperature crude oil. Traditional carbon steel pipes would rapidly succumb to sulfide stress cracking (SSC), pitting, or general corrosion. Composite pipe provides the necessary resistance for:

- Sour Service Pipelines: Transporting oil and gas with high concentrations of H2S and CO2, especially in deep-water and unconventional reservoirs, where failure is not an option.

- Offshore and Subsea Installations: Where repair and replacement are extremely costly and logistically challenging, the extended lifespan of composite pipe is invaluable for risers, flowlines, and jumpers.

- Refinery Processes: Handling corrosive intermediates and end products, such as sulfuric acid alkylation units, or crude distillation units where naphthenic acid corrosion is a concern.

Chemical Processing

The chemical industry deals with an astonishing array of corrosive substances, from strong acids and bases to aggressive organic compounds, often at elevated temperatures and pressures. Composite pipe ensures safe and reliable transport for:

- Aggressive Chemical Transport: Pipelines for hydrochloric acid, sulfuric acid, phosphoric acid, and various solvents where robust corrosion resistance is essential.

- Reactors and Heat Exchangers: Internal piping in these units often experiences severe corrosive attack, making clad pipes an ideal solution for longevity.

Water Treatment and Desalination

With increasing global water scarcity, desalination plants are proliferating. These facilities handle large volumes of seawater and highly concentrated brine, which are extremely corrosive due to high chloride content. Composite pipe offers superior performance for:

- Seawater Intake and Brine Discharge Lines: Protecting against uniform corrosion, pitting, and crevice corrosion from saline waters.

- Pipes for Corrosive Chemicals: Used in water purification processes, such as chlorine or ozone dosing systems.

Figure 2: Illustrative application of composite pipe within a complex refinery piping system, highlighting its role in high-pressure, corrosive environments.

Metallurgy and Mining

The processing of ores and metals often involves highly abrasive and corrosive slurries and acidic leaching solutions. Composite pipe can handle these punishing conditions:

- Slurry Pipelines: Transporting abrasive slurries with corrosive characteristics, such as those found in mineral processing plants.

- Acid Leaching Processes: Piping for the extraction of metals using strong acid solutions.

Power Generation

Modern power plants, especially those utilizing fossil fuels, must manage corrosive flue gases and cooling water. Composite pipe contributes to their reliability:

- Flue Gas Desulfurization (FGD) Systems: Handling acidic condensates and slurries in pollution control equipment.

- Cooling Water Systems: Especially those using brackish or seawater, where resistance to biofouling and chloride corrosion is important.

In each of these scenarios, the composite pipe minimizes downtime, reduces replacement costs, and ensures operational continuity, making it a sound investment for long-term industrial infrastructure.

Choosing the Right Steel Pipe Manufacturer: A Critical Decision

The integrity and performance of your composite pipe solutions are directly tied to the expertise and capabilities of your chosen steel pipe manufacturer. This is not a commodity purchase; it's an investment in the long-term reliability and safety of your operations. Making an informed decision requires evaluating several key factors.

Factors to Consider When Selecting Your Manufacturer:

- Experience and Track Record: Look for a manufacturer with a proven history in producing composite pipe, specifically Mechanical Clad Steel Pipe. Years in the business and a portfolio of successful projects in demanding industries are strong indicators of reliability. Lion Pipeline, for example, boasts extensive experience in delivering high-quality clad pipe solutions for diverse global projects.

- R&D and Innovation Capabilities: The best manufacturers are constantly investing in research and development to improve manufacturing processes, explore new material combinations, and enhance product performance. This ensures they can offer cutting-edge solutions for evolving industry challenges.

- Certifications and Quality Management Systems: Adherence to international standards is non-negotiable. Ensure the manufacturer holds certifications such as ISO 9001 (Quality Management), API 5L (for pipeline pipes), and can produce pipes compliant with ASTM, ASME, and NACE standards (e.g., NACE MR0175/ISO 15156 for sour service). These certifications validate their commitment to consistent quality and safety.

- Manufacturing Facilities and Technology: A tour or detailed overview of their facilities should reveal state-of-the-art equipment, advanced inspection technologies (NDT, hydrostatic testing rigs), and a clean, organized production environment. The ability to handle large diameters and long lengths is also a key consideration.

- In-house Expertise: A strong engineering and metallurgy team is crucial for understanding complex project requirements, recommending optimal material combinations, and providing technical support.

- Custom Solution Capabilities: Standard products may not always fit unique project needs. A top-tier steel pipe manufacturer should be able to offer bespoke solutions, adapting dimensions, material grades, and end preparations to your exact specifications.

- Quality Control Processes: Inquire about their detailed Quality Assurance/Quality Control (QA/QC) plan. This should cover every stage from raw material procurement to final inspection and documentation, including rigorous testing procedures for bond integrity, dimensional accuracy, and material verification.

- Global Supply Chain and Logistics: For international projects, the manufacturer's ability to manage complex logistics, ensure timely delivery, and navigate customs regulations is vital.

- After-Sales Support and Warranty: A reputable manufacturer stands behind its products, offering comprehensive warranties and responsive technical support post-delivery and installation.

By diligently evaluating these factors, you can partner with a steel pipe manufacturer who not only provides high-quality composite pipe but also acts as a reliable partner in your project's success, ensuring long-term operational excellence and peace of mind.

Tailored Solutions: Your Specific Needs, Our Expertise

In the world of industrial infrastructure, one size rarely fits all. While standard configurations of Mechanical Clad Steel Pipe can meet many requirements, the true value of an experienced steel pipe manufacturer lies in their ability to deliver highly customized solutions. Lion Pipeline prides itself on its engineering prowess and flexible manufacturing capabilities, ensuring that every composite pipe we produce is optimized for its specific application.

Customization Options for Your Composite Pipe Project:

- Material Combinations: We work closely with clients to select the ideal base pipe material (e.g., specific API 5L grades, ASTM A106, or specialized alloys) and inner liner CRA (e.g., specific grades of stainless steel, duplex, super duplex, nickel alloys like Inconel 625, Hastelloy C-276, or Titanium) to perfectly match the design pressure, temperature, and corrosive media. This optimization ensures maximum performance without unnecessary cost.

- Dimensions and Lengths: Beyond standard sizes, we can produce composite pipe in custom outer diameters, wall thicknesses, and liner thicknesses. Project-specific lengths, including extra-long sections to minimize field welds, can significantly reduce installation time and costs.

- End Preparations: Various end preparations are available to facilitate seamless integration with existing piping systems or specific welding procedures. These include plain ends, beveled ends (for welding), and specialized flange preparations.

- Special Coatings and Linings (External): For added external corrosion protection or specific environmental conditions, external coatings (e.g., FBE, 3LPE, liquid epoxy) can be applied.

- Testing and Certification: Beyond standard inspections, we can conduct additional non-destructive testing, destructive mechanical tests, and provide third-party inspection certifications as required by project specifications. This further enhances the trustworthiness of our composite pipe products.

- Logistics and Packaging: Custom packaging solutions, including robust crates for international shipping or specialized handling provisions, can be arranged to ensure safe delivery to even the most remote project sites.

Our Engineering Support and Consultation Process:

Our approach to customized solutions is collaborative. It begins with a deep understanding of your project's unique challenges and objectives:

- Needs Assessment: Our technical team engages with your engineers to thoroughly understand the operating environment, fluid properties, pressure and temperature profiles, expected service life, and regulatory requirements.

- Material Selection Guidance: Leveraging our extensive metallurgical knowledge and experience as a leading steel pipe manufacturer, we recommend the most suitable base and liner material combinations, balancing performance with cost-effectiveness.

- Design Optimization: We advise on optimal dimensions, wall thicknesses, and liner thicknesses to meet structural and corrosive requirements, often using advanced simulation tools.

- Detailed Quotation & Project Plan: A comprehensive proposal outlining technical specifications, production timelines, quality control procedures, and delivery schedules is provided.

- Project Management: A dedicated project manager oversees the entire process, from raw material sourcing and manufacturing to final inspection and logistics, ensuring seamless execution and timely communication.

Real-World Impact: Application Cases of Mechanical Clad Steel Pipe

The theoretical advantages of composite pipe are best illustrated through their successful deployment in real-world scenarios. Here are examples of how Mechanical Clad Steel Pipe consistently outperforms traditional materials, delivering significant value to diverse industries.

Case 1: Offshore Oil & Gas – Sour Gas Transport Pipeline

A major energy company faced the challenge of transporting highly corrosive sour gas (high H2S and CO2 content) from a new deep-water wellhead to an onshore processing facility. Traditional carbon steel would succumb to sulfide stress cracking (SSC) and general corrosion, necessitating frequent, costly repairs and posing significant safety risks. Solid CRA pipes (e.g., Inconel 625) were considered but deemed economically unfeasible due to the large diameter (24 inches) and extensive length required (150 km).

Solution: The project opted for composite pipe (Mechanical Clad Steel Pipe) with an API 5L X65 carbon steel base pipe and an Inconel 625 liner. This solution provided the necessary mechanical strength for deep-water pressures combined with the ultimate corrosion resistance of Inconel 625 against sour gas.

Benefits Achieved:

- Significant Cost Savings: Over 40% reduction in material costs compared to a solid Inconel 625 pipeline.

- Extended Service Life: Projected service life exceeding 30 years, drastically reducing the need for costly subsea interventions.

- Enhanced Safety: Minimized risk of leaks and environmental contamination due to the robust corrosion barrier.

- Reliable Operation: Ensured continuous flow of critical hydrocarbons without corrosion-related interruptions.

Case 2: Chemical Plant – Acidic Effluent Discharge Lines

A large chemical manufacturing facility experienced repeated failures in its wastewater discharge lines, which carried hot, acidic effluent containing various corrosive chemicals. Carbon steel pipes previously installed had a service life of less than 3 years, leading to frequent production shutdowns and environmental concerns.

Solution: The facility replaced the failing lines with composite pipe featuring an ASTM A106 Gr. B carbon steel outer pipe and a 316L stainless steel liner. For particularly aggressive sections, a 2205 Duplex stainless steel liner was utilized to combat localized corrosion.

Benefits Achieved:

- Dramatic Increase in Service Life: The new composite pipe lines have been in continuous operation for over 10 years without any corrosion-related failures, surpassing the previous pipe's lifespan by more than threefold.

- Reduced Downtime: Eliminated costly shutdowns for pipe replacement and repair, improving overall plant productivity.

- Improved Environmental Compliance: Greater confidence in preventing hazardous leaks, contributing to the plant's environmental stewardship.

Figure 3: A practical application demonstrating the versatility and resilience of composite pipe in challenging industrial settings.

Case 3: Desalination Plant – Seawater Intake Pipeline

A new large-scale reverse osmosis desalination plant in a coastal region required a robust seawater intake pipeline. The aggressive chloride environment of seawater, combined with potential for biofouling, posed a severe corrosion challenge for conventional materials. Cost for large-diameter (36 inches) solid super duplex pipe was prohibitive.

Solution: The plant opted for composite pipe with an API 5L X52 base pipe and a 2507 Super Duplex stainless steel liner. This combination provided the necessary structural strength for the large pipeline while offering unparalleled resistance to chloride-induced pitting and crevice corrosion, characteristic of seawater applications.

Benefits Achieved:

- Optimized Cost vs. Performance: Achieved superior corrosion resistance comparable to solid Super Duplex at a significantly lower capital expenditure.

- Long-Term Reliability: Guaranteed long-term, uninterrupted operation of the critical seawater intake, vital for the plant's continuous water production.

- Resistance to Biofouling: The smooth, corrosion-resistant surface of the Super Duplex liner also helps mitigate biofouling compared to rougher, corroding surfaces.

These cases vividly demonstrate how choosing the right composite pipe solution, expertly manufactured by a capable steel pipe manufacturer, can lead to substantial long-term benefits in terms of operational efficiency, cost savings, and environmental protection.

Ensuring Trust and Reliability ( Trustworthiness): Our Commitment

At Lion Pipeline, trust is not just a word; it's the foundation of every composite pipe we produce and every client relationship we build. Our commitment to Google's standards – Expertise, Experience, Authoritativeness, and Trustworthiness – is woven into every facet of our operations. We understand that for critical infrastructure, reliability is paramount.

Quality Assurance & Certifications: The Pillars of Trust

Our relentless pursuit of quality is backed by comprehensive certifications and a robust Quality Management System (QMS). We adhere strictly to international standards, ensuring that every Mechanical Clad Steel Pipe leaving our facility meets or exceeds industry benchmarks.

- ISO 9001 Certified: Our entire manufacturing process, from raw material procurement to final inspection, is governed by ISO 9001:2015, ensuring consistent quality and continuous improvement.

- API 5L & ASME Compliance: Our base pipes are manufactured and tested in accordance with API Specification 5L for line pipe, and our clad pipes can be designed and produced to meet ASME Boiler and Pressure Vessel Code (BPVC) and B31 pressure piping codes (B31.3 Process Piping, B31.4 Pipeline Transportation Systems for Liquid Hydrocarbons, B31.8 Gas Transmission and Distribution Piping Systems).

- ASTM & NACE Standards: We rigorously follow ASTM standards for materials and testing (e.g., ASTM A264 for carbon steel clad with stainless steel; ASTM A263 for carbon steel clad with chromium-nickel alloy steel; ASTM A265 for nickel and nickel-base alloy clad steel plate, adaptable for pipe liner materials). For sour service applications, our composite pipe solutions comply with NACE MR0175/ISO 15156.

- Rigorous Testing Protocols: Every batch of composite pipe undergoes extensive testing, including:

- Hydrostatic Testing: To verify leak integrity and pressure containment capacity.

- Ultrasonic Testing (UT): For 100% bond integrity verification along the entire length.

- Shear Strength Testing: Destructive tests on samples to confirm the robustness of the mechanical bond.

- Positive Material Identification (PMI): To confirm the chemical composition of both the base and liner materials, preventing material mix-ups.

- Visual & Dimensional Inspections: Ensuring precise conformity to specified dimensions and surface finish.

- Impact Testing (Charpy V-Notch): For low-temperature service applications, ensuring material toughness.

- Full Traceability: All raw materials and finished products are fully traceable from mill to client, providing complete transparency and accountability.

Delivery & Logistics: On-Time, Every Time

We understand that project timelines are critical. Our efficient supply chain management and global logistics network ensure the timely and secure delivery of your composite pipe products, whether by land or sea. Typical lead times for custom composite pipe projects range from 8 to 16 weeks, depending on material availability, complexity, and order volume. We provide transparent communication throughout the production and shipping process, offering real-time updates and coordinating closely with your logistics teams.

Figure 4: A glimpse into the meticulous quality control processes involved in manufacturing composite pipe, ensuring adherence to the highest standards.

Warranty & Customer Support: Your Partner Beyond Delivery

Our commitment extends far beyond the point of sale. We offer comprehensive quality assurance and a warranty against manufacturing defects, typically ranging from 5 to 10 years, reflecting our confidence in the durability and performance of our composite pipe. Our dedicated technical support team is always available to assist with any queries, from installation guidance to troubleshooting, ensuring your long-term satisfaction. We believe in building lasting partnerships, providing ongoing support to ensure the optimal performance of your composite pipe infrastructure throughout its lifecycle.

Frequently Asked Questions (FAQ) about Composite Pipe

Q1: What is the primary advantage of a composite pipe over a solid alloy pipe?

The primary advantage of a composite pipe (specifically clad steel pipe) over a solid alloy pipe is its exceptional cost-effectiveness. It offers the same or superior corrosion resistance and mechanical properties as a solid expensive alloy, but at a significantly lower material cost. This is because only a thin layer of the expensive corrosion-resistant alloy (CRA) is used as the liner, while the bulk of the pipe is made from more affordable carbon or low-alloy steel that provides structural strength. This leads to substantial savings, especially for large-diameter and long-distance pipelines, without compromising performance.

Q2: How are mechanical clad steel pipes manufactured, and what ensures the bond integrity?

Mechanical clad steel pipes are typically manufactured by inserting a corrosion-resistant alloy (CRA) liner pipe into a larger diameter carbon or low-alloy steel base pipe. The crucial bonding step often involves hydraulic expansion, where high-pressure fluid expands the inner liner outwards, creating a tight interference fit with the base pipe's internal wall. This mechanical bond ensures excellent contact and prevents buckling of the liner. Bond integrity is rigorously verified through non-destructive testing (NDT) methods like ultrasonic testing (UT) and destructive shear strength tests on samples, ensuring the layers remain robustly joined throughout their service life.

Q3: What are the common liner materials used in composite pipe?

The choice of liner material depends on the specific corrosive media and operating conditions. Common liner materials for composite pipe include various grades of stainless steel (e.g., 304L, 316L, 317L), duplex stainless steels (e.g., 2205), super duplex stainless steels (e.g., 2507) for enhanced resistance to pitting and stress corrosion cracking, and high-performance nickel-based alloys such as Inconel 625, Hastelloy C-276, and Incoloy 825 for highly aggressive environments, extreme temperatures, or severe sour service. Titanium is also used for specific highly oxidizing acid applications.

Q4: What industry standards apply to the design and manufacturing of mechanical clad pipes?

Several international and industry-specific standards govern the design, manufacturing, and testing of composite pipe. Key standards include API 5L (for line pipes), ASTM A264 (for carbon steel clad with stainless steel), ASTM A263 (for carbon steel clad with chromium-nickel alloy steel), and ASTM A265 (for nickel and nickel-base alloy clad steel plate). Additionally, design and installation often follow ASME B31 pressure piping codes (B31.3 Process Piping, B31.4 Liquid Hydrocarbon Pipelines, B31.8 Gas Transmission), and for sour service applications, NACE MR0175/ISO 15156 is critical. Compliance with ISO 9001 for quality management is also standard for reputable manufacturers.

Q5: Can composite pipe be welded or joined like conventional pipes?

Yes, composite pipe can be welded and joined, but it requires specialized welding procedures to ensure the integrity of both the outer base pipe and the inner liner. The welding process typically involves a two-step approach: first, welding the outer carbon/low-alloy steel layer using standard procedures for that material, and then carefully welding the inner CRA liner using specific welding consumables and techniques (e.g., TIG welding with appropriate filler metals) to maintain its corrosion resistance. Experienced welders with specific certifications for clad materials are essential. Reputable manufacturers provide detailed welding procedures (WPS) to guide this process.

Q6: What is the typical service life of a mechanical clad steel pipe?

The typical service life of a well-engineered and properly installed mechanical clad steel pipe in its intended application can be significantly longer than that of conventional pipes. Depending on the specific material combination, operating conditions, and maintenance practices, composite pipe can reliably perform for 30 to 50 years or even longer. This extended lifespan is a major economic benefit, drastically reducing replacement frequency and associated downtime and costs compared to pipes that are susceptible to internal corrosion.

Q7: What industries benefit most from using composite pipe?

Industries that benefit most from using composite pipe are those that handle corrosive or abrasive fluids at high pressures and/or temperatures, or where long service life and minimal maintenance are critical. These primarily include:

- Oil & Gas (Upstream, Midstream, Downstream): For sour service, offshore, subsea, and refinery applications.

- Chemical Processing: For transporting aggressive acids, bases, and solvents.

- Water Treatment & Desalination: For handling corrosive seawater and brines.

- Power Generation: For FGD systems and cooling water lines.

- Metallurgy & Mining: For abrasive and corrosive slurry transport and acid leaching processes.

The value proposition in these sectors is driven by the need for superior corrosion resistance without the prohibitive cost of solid exotic alloys.

Ready to enhance your infrastructure with the unparalleled performance of Mechanical Clad Steel Pipe? As a premier steel pipe manufacturer, we are ready to provide custom solutions tailored to your project's unique demands.

Discover Our Mechanical Clad Steel Pipe Solutions

References & Further Reading