In an era defined by relentless technological advancement and increasingly stringent operational demands, the foundational elements of industrial infrastructure are undergoing a profound transformation. Traditional piping systems, predominantly relying on conventional metallic materials, are frequently reaching their operational limits when confronted with corrosive environments, extreme temperatures and pressures, and the overarching imperative for enhanced sustainability and reduced lifecycle costs. This paradigm shift necessitates a robust and innovative alternative, one that not only addresses extant challenges but also proactively anticipates future requirements for durability, efficiency, and environmental responsibility. Against this backdrop, the advent and maturation of composite pipe technology stand out as a pivotal development, heralding a new era of performance for critical fluid conveyance systems across diverse industrial sectors. This innovative class of piping combines the inherent strengths of various materials, often featuring a synergistic multi-layered structure, to deliver superior performance characteristics that far exceed the capabilities of single-material counterparts. The global industrial landscape is increasingly gravitating towards solutions that promise extended service life, minimal maintenance downtime, and optimized energy consumption, all while adhering to the most rigorous safety and environmental protocols. This trend is particularly pronounced in high-stakes sectors such as oil and gas, petrochemical processing, municipal water infrastructure, and specialized chemical manufacturing, where the economic and environmental repercussions of pipeline failure are astronomically high. Consequently, the demand for sophisticated piping solutions that can withstand aggressive chemical attack, offer exceptional mechanical integrity under dynamic loads, and facilitate smoother fluid flow without significant energy losses, has spurred significant investment in research and development. The commitment of leading manufacturers to integrate cutting-edge materials science with advanced fabrication techniques, such as those exemplified by Laser Clad Pipe technology, underscores this industry-wide evolution. This particular innovation represents a significant leap forward, offering unparalleled bonding strength and corrosion resistance, thereby setting new benchmarks for performance in the most demanding operational contexts. The strategic imperative for adopting such advanced piping solutions is not merely confined to mitigating immediate operational risks; it extends to achieving long-term strategic advantages, including significant reductions in capital expenditure for replacements, lower operational expenditure through minimized maintenance, and a substantial positive impact on environmental footprints by preventing leaks and extending asset lifecycles. As industries globally strive for higher efficiencies and greater resilience in their operational frameworks, the adoption of meticulously engineered and impeccably manufactured composite pipe systems becomes not just an option, but a critical component of a forward-thinking and sustainable infrastructure strategy, empowering businesses to achieve unprecedented levels of operational excellence and reliability. The comprehensive advantages offered by these multi-material solutions position them as indispensable assets for the next generation of industrial applications, providing a robust foundation for enduring operational success and a competitive edge in a rapidly evolving global market. The ongoing investment by a leading composite pipe manufacturer in advanced research and development underscores the continuous evolution of this technology, ensuring that future iterations will meet even more complex demands.

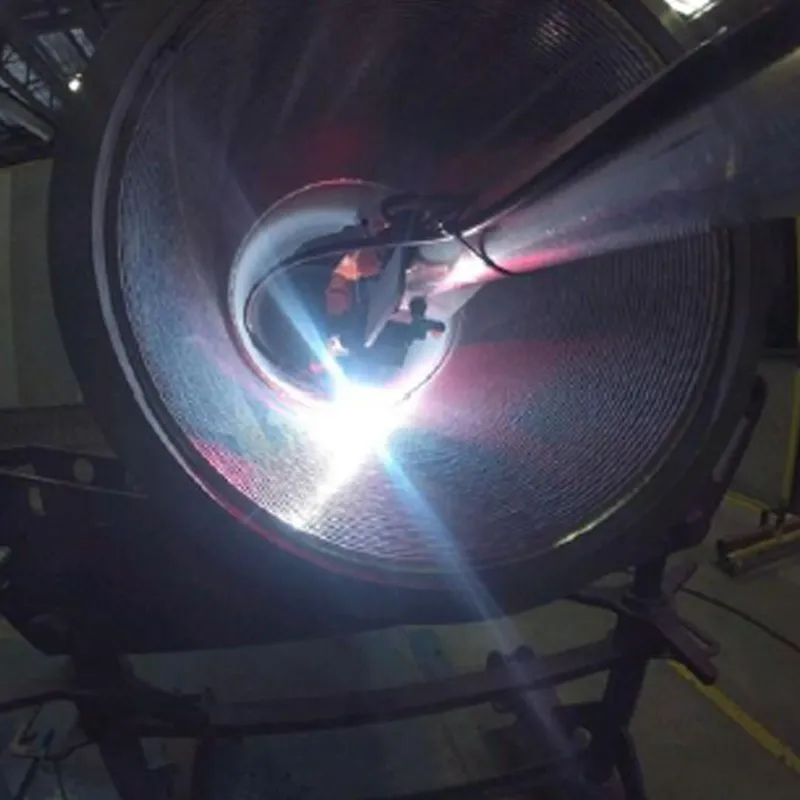

A composite pipe is fundamentally an engineered material system, meticulously designed to leverage the distinct advantages of multiple constituent components, creating a product with superior properties compared to any single material used in isolation. Typically, these pipes consist of several layers, each serving a specific function: an inner liner for chemical resistance and smooth fluid flow, structural layers for mechanical strength and pressure containment, and an outer layer for environmental protection. Common materials incorporated into these complex structures include high-performance polymers such as polyethylene (PE), polypropylene (PP), and polyvinylidene fluoride (PVDF) for the liner, often chosen for their exceptional chemical inertness and low friction coefficients. The structural layers frequently utilize high-strength fibers like fiberglass (GFRP - Glass Fiber Reinforced Polymer) or carbon fiber (CFRP - Carbon Fiber Reinforced Polymer), impregnated with thermosetting resins such as epoxy, vinyl ester, or polyester. These fiber-reinforced layers are responsible for the pipe's remarkable tensile strength, stiffness, and resistance to internal pressure. The manufacturing processes for these sophisticated structures are highly specialized, often involving advanced techniques like filament winding, pultrusion, or co-extrusion. Filament winding, a predominant method for creating high-pressure composite pipes, involves continuously winding resin-impregnated fibers onto a rotating mandrel in precise patterns to achieve optimal strength and stiffness. Pultrusion, conversely, pulls continuous fibers through a resin bath and then a heated die, forming a constant cross-section. Co-extrusion allows for the simultaneous extrusion of multiple layers, enabling the creation of intricate multi-material profiles. For specialized applications requiring extreme corrosion resistance or wear resistance, such as the Laser Clad Pipe, a unique cladding process is employed. This advanced technique involves using a high-power laser to melt and fuse a metallic powder (e.g., nickel-based alloys, stainless steels, or other corrosion-resistant alloys) onto the inner surface of a base pipe, often a steel pipe. This laser cladding creates a metallurgical bond, offering an exceptionally durable and impermeable barrier against aggressive media. This process ensures zero porosity and superior adhesion, differentiating it significantly from conventional welding or coating methods. The selection of materials and manufacturing processes is meticulously calibrated based on the intended application, accounting for factors such as operating temperature, pressure, chemical compatibility, and external environmental conditions. The synergy between material science and advanced engineering design allows composite pipe systems to offer unparalleled performance in scenarios where traditional steel or plastic pipes would quickly degrade or fail.

The performance of a composite pipe is quantifiable through a comprehensive set of technical parameters, which are rigorously defined and tested to ensure compliance with international industry standards. These parameters are crucial for engineers and procurement specialists to accurately assess suitability for specific projects. Key among these are the pipe's nominal diameter (DN) and outer diameter (OD), which dictate flow capacity and compatibility with existing infrastructure. Pressure ratings, typically expressed as Maximum Allowable Operating Pressure (MAOP) or design pressure, are critical and vary widely based on the composite structure, material selection, and fiber orientation during manufacturing, ranging from low-pressure applications (e.g., 10 bar) to ultra-high-pressure applications exceeding 300 bar for specialized oil and gas pipelines. Temperature ratings define the minimum and maximum temperatures at which the pipe can safely operate without compromising its structural integrity or chemical resistance, spanning from cryogenic conditions to temperatures exceeding 150°C for high-temperature fluid transport. Chemical resistance is evaluated against a broad spectrum of industrial chemicals, acids, bases, and hydrocarbons, often detailed in compatibility charts, ensuring the inner liner can withstand the transported media without degradation over decades of service. Mechanical properties, including tensile strength, flexural strength, and hoop strength, are paramount for assessing the pipe's resistance to external loads, internal pressure, and bending forces. The service life of a composite pipe is often projected to be 30 to 50 years or more, significantly longer than many metallic alternatives, due to their inherent corrosion resistance and fatigue properties. Furthermore, hydraulic efficiency, characterized by a significantly lower Manning roughness coefficient compared to steel pipes, translates directly into energy savings due to reduced friction losses, making them an economically attractive long-term investment. Adherence to international inspection and quality assurance standards is non-negotiable for a reputable composite pipe manufacturer. Key standards include ISO 14692 for petroleum and natural gas industries, which specifies requirements for the qualification and design of glass-reinforced plastic (GRP) piping systems; ANSI/AWWA C950 for Fiberglass Pressure Pipe, widely adopted in water and wastewater applications; and various ASTM standards (e.g., ASTM D2996 for Filament-Wound Fiberglass Pipe, ASTM D3262 for Fiberglass Sewer and Industrial Pressure Pipe). For products like Laser Clad Pipe, which incorporate metallic components, relevant API (American Petroleum Institute) specifications for line pipe and cladding materials (e.g., API 5L, API 6A, NACE MR0175/ISO 15156 for sour service applications) are also critical. Rigorous testing protocols, encompassing hydrostatic pressure tests, cyclic fatigue tests, chemical immersion tests, and non-destructive testing (NDT) methods like ultrasonic testing and radiographic inspection, ensure every segment meets or exceeds these stringent benchmarks, guaranteeing reliable and safe operation throughout its extended lifespan. This meticulous approach to engineering, manufacturing, and quality control underpins the exceptional performance and longevity of advanced composite pipe systems, distinguishing them as a premier choice for challenging industrial applications.

| Parameter | Description | Typical Range/Value | Relevant Standard/Note |

|---|---|---|---|

| Diameter Range | Nominal Pipe Size (NPS) / Diameter Nominal (DN) | DN 25 (1") to DN 2000 (80") or larger | Customizable based on flow requirements |

| Pressure Rating | Maximum Allowable Operating Pressure (MAOP) | 10 bar (150 psi) to 350 bar (5000+ psi) | ISO 14692, ANSI/AWWA C950, ASME B31.3 |

| Temperature Range | Operational temperature limits | -40°C (-40°F) to +180°C (356°F) | Material specific (e.g., epoxy vs. vinyl ester resins) |

| Material Composition (Layers) | Inner liner, structural layers, outer layer | PE, PP, PVDF (liner); Fiberglass, Carbon Fiber (reinforcement); Epoxy, Vinyl Ester (resin); Steel, CRA (cladding) | Tailored to fluid chemistry & external environment |

| Corrosion Resistance | Resistance to chemical attack and electrochemical degradation | Excellent against acids, alkalis, salts, hydrocarbons | Superior to most metallic pipes (e.g., carbon steel) |

| Service Life Expectancy | Expected operational lifespan under design conditions | 30 to 50+ years | Dependent on correct installation and operating conditions |

| Roughness Coefficient (Manning's n) | Indicator of internal surface smoothness and friction loss | Typically 0.009 - 0.010 | Lower than steel (0.012), concrete (0.013-0.017) |

| Weight | Pipe weight per unit length | Approximately 1/5th to 1/10th of equivalent steel pipe | Significant savings in transport & installation costs |

| Thermal Conductivity | Heat transfer capability through pipe wall | Lower than metallic pipes (good insulation) | Reduced heat loss/gain, potential energy savings |

| UV Resistance | Resistance to degradation from ultraviolet radiation | Good, often with UV-stabilized outer layer | Important for above-ground installations |

The versatility and superior performance characteristics of advanced composite pipe systems have enabled their widespread adoption across an increasingly diverse array of industries, each benefiting from their unique attributes. In the critically important petrochemical and oil & gas sectors, where pipelines operate under conditions of extreme pressure, high temperatures, and exposure to highly corrosive media such as sour gas (H2S), CO2, and brines, composite pipe solutions offer an indispensable alternative to expensive and maintenance-intensive corrosion-resistant alloys or internally coated steel pipe manufacturer products. Their inherent resistance to internal and external corrosion drastically reduces the risk of leaks, environmental contamination, and catastrophic failures, thereby enhancing operational safety and significantly extending asset lifecycles. Furthermore, the lightweight nature of these pipes simplifies transportation and installation, particularly in challenging remote or offshore environments, leading to substantial reductions in logistics and labor costs. In the municipal water supply and wastewater treatment sectors, composite pipes are increasingly replacing aging metallic and concrete infrastructure. Their smooth internal bore minimizes head loss, translating into tangible energy savings for pumping stations, and their resistance to tuberculation and scaling ensures consistent flow rates over decades without degradation of water quality or capacity. The non-corrosive nature of these pipes also eliminates concerns about pipe material leaching into potable water, upholding public health standards. For the mining industry, particularly in tailings disposal and slurry transport, the superior abrasion resistance and chemical inertness of composite pipes prevent premature wear and chemical attack, offering a far more robust solution than traditional steel pipes which are prone to rapid degradation in such harsh, abrasive environments. In the chemical processing industry, where a vast array of aggressive chemicals must be transported safely, the tailored chemical resistance of composite liners, combined with the structural integrity of fiber reinforcements, provides a reliable and long-lasting conveyance system, minimizing the risks of spills and ensuring process continuity.

Beyond these traditional applications, the advantages of composite pipe systems extend to burgeoning sectors such as renewable energy, including geothermal power plants and offshore wind farms, where their resistance to corrosive geothermal fluids and saltwater, coupled with their structural resilience, makes them ideal for demanding long-term projects. The manufacturing processes involved, particularly for advanced solutions like Laser Clad Pipe, represent a pinnacle of engineering precision, guaranteeing optimal material synergy. This specific technology, with its laser-fused metallic inner layer, offers an unparalleled defense against the most aggressive corrosive agents while leveraging the structural benefits of a traditional pipe body, often steel, for robust mechanical support. This hybrid approach delivers the best of both worlds: the mechanical strength and familiarity of steel, combined with the superior corrosion resistance of high-performance alloys achieved through advanced cladding. The technical advantages are manifold and profoundly impact the total cost of ownership (TCO). Foremost is the unparalleled corrosion resistance, which is critical in preventing degradation from aggressive chemicals, saline environments, and microbial induced corrosion (MIC). This feature alone can extend pipe life by several decades compared to unprotected steel, dramatically reducing replacement frequencies and associated capital expenditures. Secondly, their lightweight nature, often one-fifth to one-tenth the weight of equivalent steel pipes, significantly reduces transportation costs, eases handling during installation, and lessens the load on supporting structures, leading to faster and more economical project execution. Thirdly, the inherently smooth inner surfaces of composite pipes result in lower friction coefficients and reduced fluid turbulence. This translates directly into energy savings for pumping systems, as less energy is required to move fluids over long distances, contributing to lower operational expenditure and a reduced carbon footprint. Furthermore, the excellent fatigue resistance and resistance to external environmental factors like UV radiation and seismic activity make composite pipes exceptionally durable and resilient. Unlike steel, they do not suffer from internal scaling or tuberculation, maintaining consistent flow capacity over their entire service life, which is a significant advantage for long-term operational efficiency. These attributes culminate in a product that not only offers superior performance but also delivers substantial economic benefits through extended asset life, reduced maintenance, and enhanced operational efficiency, making the investment in composite pipe technology a strategically sound decision for future-proofing industrial infrastructure. The integration of cutting-edge manufacturing techniques, such as those championed by a leading composite pipe manufacturer like Lion Pipeline, ensures that these advantages are fully realized, providing clients with robust, reliable, and cost-effective solutions for their most challenging piping requirements across the globe.

Illustration of a typical composite pipe structure, highlighting multi-layered design for optimal performance.

Choosing the right composite pipe manufacturer is paramount for securing reliable, high-performance piping solutions that align with the precise demands of complex industrial operations. The landscape of manufacturers is diverse, ranging from established giants with broad product portfolios to highly specialized innovators focusing on niche, advanced technologies. A truly leading composite pipe manufacturer is distinguished not merely by its product range but by its unwavering commitment to innovation, its depth of technical expertise, and its proven ability to deliver highly customized solutions. Innovation, exemplified by breakthroughs like Laser Clad Pipe technology, represents the vanguard of modern piping solutions. While many composite pipes rely on polymer liners and fiber reinforcements, the integration of laser cladding introduces a new dimension of durability and performance. This process involves the precision deposition of an ultra-hard, corrosion-resistant metallic alloy onto the inner surface of a base pipe, often a robust steel pipe, through a laser-melting process. The result is a metallurgical bond that far surpasses the adhesion and integrity of traditional mechanical linings or welded overlays, providing unparalleled resistance to extreme abrasive wear and chemical attack in the most aggressive environments, such as those encountered in upstream oil and gas or challenging chemical processing plants. This level of technological sophistication requires substantial investment in research and development, advanced material science laboratories, and highly skilled engineering teams proficient in metallurgy, fluid dynamics, and stress analysis. Such a manufacturer not only produces pipes but also acts as a critical technical partner, capable of providing in-depth consultation on material selection, design optimization, and installation methodologies. When evaluating manufacturers, it is essential to look beyond standard product offerings and assess their capabilities in bespoke engineering. Every industrial project presents unique challenges—be it specific pressure and temperature profiles, unusual chemical compositions of transported media, or complex geographical constraints. A top-tier composite pipe manufacturer excels in offering tailored solutions, adapting pipe dimensions, material combinations, pressure ratings, and even connection types to meet exact project specifications. This involves iterative design processes, advanced simulation techniques, and prototyping to ensure the customized solution performs optimally under projected operating conditions.

A key differentiator for a discerning client lies in the manufacturer’s capacity for general industry comparison and strategic partnerships. While direct comparisons between competing companies are often proprietary, it is beneficial to understand the different approaches adopted by various players. Some manufacturers might specialize in standard FRP/GRP pipes for municipal applications, prioritizing cost-effectiveness and volume. Others, including leading steel pipe manufacturers that have diversified, might offer a broader portfolio including both traditional steel and nascent composite solutions. However, a truly specialized composite pipe manufacturer typically focuses on high-performance applications, investing heavily in advanced materials and manufacturing processes like filament winding for high-pressure applications or the sophisticated laser cladding for severe corrosion environments. This specialization often translates into deeper technical expertise and a more robust quality assurance framework specifically tailored to composite materials. Furthermore, the strategic alliances a manufacturer cultivates are indicative of their industry standing and collaborative capabilities. Partnerships with major engineering, procurement, and construction (EPC) firms, research institutions, and raw material suppliers demonstrate a commitment to integrated solutions and continuous improvement. These collaborations ensure that the manufacturer remains at the forefront of material science and engineering best practices, allowing them to anticipate industry needs and develop next-generation solutions. For example, a composite pipe manufacturer that collaborates closely with leading metallurgy experts can fine-tune the alloy compositions used in Laser Clad Pipe for even greater resistance to specific corrosive agents. Ultimately, the choice of manufacturer influences not just the quality of the product, but the long-term reliability of an entire infrastructure. A manufacturer that champions innovation, provides extensive customization options, and demonstrates a deep understanding of complex engineering challenges offers more than just pipes; they offer integrated, future-proof piping solutions that enhance operational efficiency, minimize risks, and deliver exceptional value throughout the project lifecycle. This holistic approach ensures that every composite pipe delivered is not merely a component, but a critical asset engineered for enduring performance in the most demanding industrial settings.

In the highly specialized and capital-intensive domain of industrial piping, establishing and maintaining credibility is paramount. For a composite pipe manufacturer, adhering to Google's (Expertise, Experience, Authoritativeness, Trustworthiness) standards is not merely an SEO best practice but a fundamental pillar of business success, fostering profound client confidence and enduring partnerships. Expertise in this field is demonstrated through an unparalleled depth of technical knowledge regarding advanced materials science, complex fluid dynamics, and precision engineering. This translates into the capacity to not only produce but also comprehensively explain the intricacies of multi-layered pipe structures, the rationale behind specific material selections (e.g., why a PVDF liner is chosen for aggressive chemical media, or why specific carbon fiber weave patterns optimize hoop strength), and the sophisticated mechanics of processes like filament winding or laser cladding. An expert composite pipe manufacturer employs a team of highly qualified metallurgists, chemical engineers, mechanical engineers, and process specialists who collectively possess decades of experience in designing, testing, and deploying high-performance piping systems for the most challenging industrial applications. This expertise is reflected in the ability to troubleshoot complex issues, innovate solutions for novel problems, and provide detailed technical specifications that empower clients to make informed decisions. Furthermore, continuous investment in research and development, alongside participation in industry forums and contributions to technical standards committees, are clear indicators of a manufacturer's commitment to advancing the state-of-the-art in composite pipe technology. This depth of understanding ensures that every product, from standard offerings to highly customized solutions like Laser Clad Pipe, is engineered with meticulous attention to detail and a profound comprehension of its intended operational environment, thereby guaranteeing optimal performance and longevity under the most arduous conditions, surpassing the capabilities of conventional steel pipe manufacturer offerings.

Experience, the second tenet of , is tangibly demonstrated through a proven track record of successful deployments and verifiable client feedback. A reputable composite pipe manufacturer will have a rich portfolio of application scenarios, detailing how their products have solved specific challenges for clients worldwide. This includes real-world instances where their pipes have withstood highly corrosive crude oil, aggressive chemical effluents, high-pressure natural gas, or challenging subsea environments over extended periods. For instance, recounting a project where a major petrochemical refinery significantly reduced downtime and maintenance costs by replacing traditional steel lines with advanced composite pipes, or an offshore platform achieving unprecedented operational reliability due to the superior corrosion resistance of laser-clad solutions, provides powerful evidence of practical effectiveness. Client testimonials and case studies, ideally with quantifiable benefits (e.g., "reduced total cost of ownership by 40% over 10 years," "extended asset life by 25 years"), are invaluable. These narratives showcase not just the product's performance but also the manufacturer's ability to execute complex projects, provide timely support, and ensure seamless integration. Years in service for the company itself, alongside the cumulative experience of its key personnel, serve as crucial indicators of an established and reliable partner. Authoritativeness is built upon official recognition, industry adherence, and independent validation. This is evidenced by an array of certifications and adherence to global standards: ISO 9001:2015 for Quality Management Systems, ensuring consistent quality in design, development, production, installation, and servicing; API Q1 for manufacturers supplying to the petroleum and natural gas industries, signifying compliance with rigorous quality specifications; and adherence to specific product standards like ISO 14692, ASTM, and ASME B31.3. These certifications are not mere badges but represent a commitment to stringent quality control, verifiable processes, and continuous improvement. Strategic partnerships with engineering firms, industry associations, and regulatory bodies further solidify a manufacturer's authoritative standing, demonstrating their active role in shaping industry best practices. Test data from independent third-party laboratories, presented in clear tables and charts detailing performance under various stress conditions (e.g., burst pressure tests, cyclic fatigue tests, long-term creep resistance), provides objective, verifiable proof of product claims, lending substantial weight to the manufacturer's authority in the field.

Trustworthiness, the final and perhaps most critical component of , is cultivated through transparency, reliability, and robust customer support mechanisms. A truly trustworthy composite pipe manufacturer provides clear and comprehensive information, anticipating and addressing client concerns proactively. An extensive Frequently Asked Questions (FAQ) module on their website or in their technical documentation, addressing common queries regarding material compatibility, installation procedures, maintenance requirements, and economic benefits versus conventional piping, is essential. Transparency regarding delivery schedules, from initial inquiry and design consultation through manufacturing, quality inspection, logistics, and final delivery, builds confidence. Clients need clear timelines and consistent communication to plan their projects effectively. A reliable manufacturer will provide detailed project schedules, regular progress updates, and contingency plans for unforeseen circumstances. Crucially, a robust quality assurance (QA) program, going beyond mere inspection to encompass rigorous testing at every stage of the manufacturing process (from raw material incoming inspection to final hydrostatic testing), is a cornerstone of trustworthiness. This includes providing comprehensive material test reports (MTRs) and non-destructive testing (NDT) results for each pipe segment. Furthermore, explicit warranty commitments that clearly outline the scope of coverage, duration, and dispute resolution processes demonstrate confidence in their product's longevity and performance. Finally, exemplary customer support, extending beyond sales to include comprehensive post-delivery services such as technical assistance for installation and commissioning, on-site training for client personnel, and readily available support for troubleshooting or future modifications, completes the picture of a trustworthy partner. This holistic approach to client engagement, ensuring seamless communication and unparalleled support throughout the entire lifecycle of the piping system, reinforces the manufacturer's commitment to long-term client success and establishes them as an indispensable resource in the highly demanding industrial sector. A composite pipe manufacturer that consistently delivers on these principles not only earns the trust of its clients but also establishes itself as an undisputed leader in the global market for advanced piping solutions, setting a benchmark for reliability and excellence.

The theoretical advantages of composite pipe technology are profoundly underscored by their demonstrable real-world impact across a multitude of challenging industrial applications. These aren't merely incremental improvements; they represent transformative shifts in operational efficiency, safety, and long-term economic viability. Consider a multinational energy company facing severe internal corrosion in its crude oil gathering lines in a highly saline and sour gas-rich field. Traditional carbon steel pipes, even with protective coatings, were requiring frequent replacement, leading to significant production losses, spiraling maintenance costs, and elevated environmental risks due to leaks. By strategically implementing advanced composite pipe solutions, specifically those featuring high-performance internal liners designed for extreme chemical resistance and structural integrity for high-pressure service, the company achieved a paradigm shift. The superior corrosion resistance of the composite pipe eliminated the need for chemical inhibitors, reducing operational expenditures, and extended the pipeline's expected service life from 5-7 years to over 30 years. This not only provided an immediate return on investment through reduced replacement costs but also dramatically enhanced environmental protection by virtually eliminating leaks, contributing to the company's sustainability goals. Another compelling case involves a large municipal water utility struggling with aging cast iron and concrete water mains that were prone to leaks, tuberculation, and frequent bursts, leading to substantial water loss, disrupted service, and high repair costs. The decision to upgrade to large-diameter composite pipes, specifically engineered for potable water conveyance, yielded remarkable benefits. The pipes' lightweight nature drastically sped up installation, reducing project timelines and community disruption. Their smooth, non-corroding interior surfaces ensured consistent flow capacity without the buildup of scale or biofilm, which in turn reduced pumping energy consumption by an estimated 15-20% due to lower friction losses, directly translating into tangible energy savings for the municipality. Furthermore, the inherent durability and resistance to external soil conditions eliminated concerns about future corrosion or degradation, guaranteeing a reliable water supply infrastructure for future generations, showcasing the long-term cost-effectiveness and operational advantages that a leading composite pipe manufacturer can deliver. These examples highlight not just the product's performance but the strategic value provided by innovative piping solutions that address core operational challenges with foresight and precision.

The trajectory of composite pipe technology is poised for continuous evolution, driven by ongoing research in material science, advanced manufacturing techniques, and the increasing demand for sustainable and resilient infrastructure. One significant future trend is the development of "smart pipes" integrated with embedded sensors. These sensors, often fiber optic or micro-electromechanical systems (MEMS), will enable real-time monitoring of critical parameters such as internal pressure, temperature, flow rates, and even the detection of minute leaks or structural anomalies. This proactive monitoring capability will revolutionize pipeline integrity management, allowing operators to identify potential issues before they escalate, optimize maintenance schedules, and significantly enhance overall safety and reliability. Such innovations represent a quantum leap beyond traditional inspection methods, moving towards a truly predictive maintenance paradigm. Another area of intense focus is the development of next-generation materials, including advanced thermoplastic composites and nanotechnology-enhanced polymers. These materials promise even greater strength-to-weight ratios, enhanced thermal stability, and superior resistance to extremely aggressive chemical environments, further expanding the application envelope of composite pipes into increasingly challenging sectors. The integration of self-healing polymers, which can automatically repair micro-cracks and minor damage, is also on the horizon, promising to further extend service life and reduce maintenance interventions. Furthermore, the push towards greater sustainability will see increased emphasis on manufacturing processes that minimize energy consumption and waste, as well as the development of fully recyclable composite materials at the end of their exceptionally long service life. The synergistic collaboration between academic research institutions, leading composite pipe manufacturers like Lion Pipeline, and key industry stakeholders will be instrumental in driving these innovations from concept to commercial reality. As industries worldwide continue to grapple with aging infrastructure, escalating operational costs, and urgent environmental imperatives, the role of advanced piping solutions will only become more critical. The commitment to innovation, such as the continuous refinement of Laser Clad Pipe technology to push the boundaries of corrosion and wear resistance, underscores a proactive approach to future demands. This ensures that composite pipes remain at the forefront of engineering solutions, providing robust, efficient, and sustainable arteries for the world's most vital industrial processes, thereby contributing significantly to global energy efficiency, environmental protection, and economic prosperity for decades to come. The transformative journey of industrial piping is far from complete, with composite pipe technology leading the charge towards a more resilient and sustainable future.

In summation, the paradigm shift from conventional metallic piping to advanced composite pipe solutions represents more than just an engineering evolution; it is a strategic imperative for industries striving for enhanced operational efficiency, superior safety, and long-term sustainability. The multi-layered design, incorporating high-performance polymers and fiber reinforcements, coupled with cutting-edge manufacturing processes like filament winding and the revolutionary Laser Clad Pipe technology, provides an unparalleled combination of corrosion resistance, lightweight strength, and hydraulic efficiency. These attributes collectively translate into significantly reduced lifecycle costs, extended asset longevity, and a substantial positive impact on environmental footprints by mitigating leaks and minimizing energy consumption. From the extreme conditions of the oil and gas sector to the critical infrastructure of municipal water systems and the demanding environments of chemical processing, composite pipes have consistently proven their superiority, outperforming traditional materials under the most arduous operational scenarios. The commitment of a leading composite pipe manufacturer like Lion Pipeline to continuous innovation, rigorous quality control evidenced by adherence to global standards such as ISO and API, and the provision of highly customized solutions, establishes them as indispensable partners for B2B decision-makers and technical personnel. Their deep expertise, extensive experience demonstrated through successful project deployments, and unwavering trustworthiness in terms of quality assurance, delivery transparency, and comprehensive post-sales support, collectively build the critical confidence required in high-stakes industrial ventures. As global industries face increasingly complex challenges, from aging infrastructure to more stringent environmental regulations and the relentless pursuit of operational excellence, the strategic adoption of advanced composite pipe systems is no longer a luxury but a fundamental component of a resilient and future-proof infrastructure strategy. Investing in these innovative solutions is a direct investment in a safer, more efficient, and sustainable industrial future, ensuring reliable fluid conveyance for generations to come and solidifying the competitive edge for forward-thinking enterprises across the globe. The trajectory of this technology continues to ascend, promising even more sophisticated capabilities through smart integration and advanced material science, reinforcing its pivotal role in shaping the next era of industrial infrastructure.

Anti Corrosion And Thermal Insulation Products

Overlay Welding Clad Steel Pipe

Where to Buy Stainless Steel Pipes and Tubing for Sale Together

The Future of Smart Flange Technology

Tee Pipe Fitting in Industrial Process Piping

Prefabricated Pipe in Shipbuilding Applications

How Anti Corrosion Pipe Extends Pipeline Lifespan

Cts Pipe Fittings for Potable Water Systems

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.