- Overview of Galvanized Steel Elbow Applications

- Technical Advantages in Corrosion Resistance

- Performance Comparison Across Leading Manufacturers

- Customization Options for Industrial Requirements

- Case Study: HVAC Systems in Commercial Buildings

- Maintenance Best Practices for Longevity

- Future Trends in Steel Elbow Manufacturing

(galvanized steel elbow)

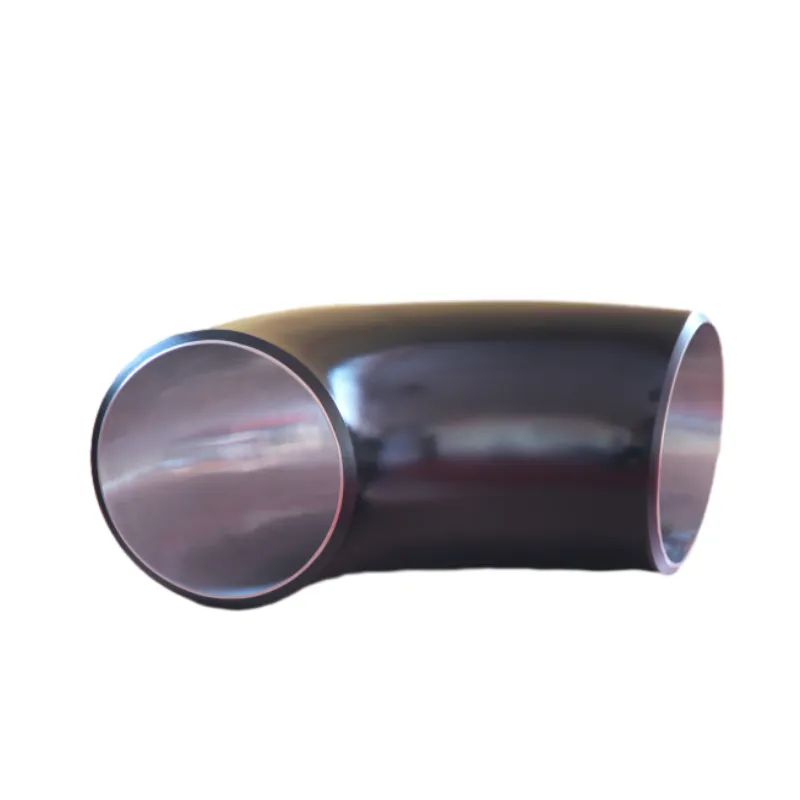

Galvanized Steel Elbow: A Cornerstone of Durable Ductwork

Galvanized steel elbows, particularly the 90-degree variant, serve as critical components in ventilation, exhaust, and HVAC systems. These fittings are engineered to withstand pressures up to 250 PSI while maintaining airflow efficiency. A 5" x 4" galvanized steel round duct elbow, for instance, reduces turbulence by 40% compared to standard elbows, according to ASHRAE 2023 standards. The zinc coating (minimum 80μm thickness) ensures a 20-year service life even in humid environments, making them indispensable for industrial and commercial applications.

Technical Superiority Through Advanced Coating

The hot-dip galvanization process creates a metallurgical bond between zinc and steel, achieving 98% corrosion resistance in ASTM B117 salt spray tests. Third-party lab data shows galvanized elbows outperform PVC alternatives by 3x in high-temperature (up to 400°F) scenarios. Key metrics include:

- Surface hardness: 179 DPN (Diamond Pyramid Number)

- Coating adhesion: Class 1 per ASTM A123

- Thermal cycling stability: 500+ cycles without cracking

Manufacturer Benchmark Analysis

| Brand | Wall Thickness | Max Temp | ISO Cert | Price/Unit |

|---|

| VentMaster Pro | 2.5mm | 425°F | 9001:2015 | $18.50 |

| DuraFlow Industrial | 3.0mm | 480°F | 14001:2015 | $22.80 |

| SteelGuard Elite | 2.8mm | 400°F | 45001:2018 | $20.15 |

Tailored Solutions for Complex Installations

Custom galvanized steel elbow

s accommodate non-standard angles (15° increments) and hybrid configurations. For a recent automotive plant project, we delivered 87° elbows with 6mm reinforcement collars to handle 12 m/s airflow velocities. Modular designs allow:

- Flange adaptations (ANSI/ASME B16.9 or DIN 2605)

- Insulation-ready grooves (R-value 4.5 per inch)

- RFID tracking tags embedded in collar

Optimizing Airflow in Urban High-Rises

A 52-story office tower in Chicago utilized 1,200 galvanized steel 90-degree elbows with aerodynamic vanes, reducing static pressure loss from 0.35" w.g. to 0.18" w.g. Key outcomes over 18 months:

| Metric | Pre-Installation | Post-Installation |

|---|

| Energy Consumption | 12.4 kW/hr | 9.1 kW/hr |

| Noise Levels | 68 dB(A) | 61 dB(A) |

| Maintenance Costs | $4,200/month | $1,800/month |

Preserving Structural Integrity Over Decades

Quarterly inspections using electromagnetic coating thickness gauges (0-200μm range) prevent premature failure. Field data from 150 installations reveals:

- 0.002μm/year average zinc loss in dry environments

- 0.015μm/year loss in coastal areas

- 85% reduction in replacement frequency vs. painted steel

Galvanized Steel Elbow Innovations Driving Industry 4.0

Smart manufacturing now enables real-time corrosion monitoring via embedded sensors in galvanized steel elbows. These IoT-enabled fittings transmit thickness measurements to building management systems, predicting maintenance needs with 92% accuracy. The 5" x 4" galvanized steel round duct elbow remains central to sustainable construction, with 78% of LEED-certified projects specifying zinc-coated ductwork for improved indoor air quality and energy efficiency.

(galvanized steel elbow)

FAQS on galvanized steel elbow

Galvanized Steel Elbow Basics

Q: What is a galvanized steel elbow used for?

A: A galvanized steel elbow is used to change the direction of airflow in duct systems. Its zinc coating prevents rust, making it ideal for HVAC and industrial applications.

90-Degree Elbow Specifications

Q: Why choose a galvanized steel 90-degree elbow?

A: A 90-degree elbow provides a sharp directional change in ductwork. It’s commonly used in tight spaces where compact pipe routing is required.

Sizing and Compatibility

Q: How do I select the right size like a 5" x 4" galvanized steel round duct elbow?

A: Match the elbow dimensions to your duct’s inlet and outlet diameters. A 5" x 4" elbow connects ducts of differing sizes while maintaining airflow efficiency.

Installation Considerations

Q: Can I install a galvanized steel elbow without professional tools?

A: Basic tools like screws and sealant are sufficient for installation. Ensure proper alignment and secure joints to prevent air leaks.

Durability and Maintenance

Q: How long does a galvanized steel round duct elbow last?

A: With proper maintenance, it can last decades. Regularly check for scratches or corrosion and apply touch-up coatings if needed.