- Introduction to composite resin tube

technology and core benefits

- Performance advantages over traditional materials with data

- Leading composite tube manufacturers comparison

- Technical specifications comparison table

- Custom engineering solutions for industry-specific requirements

- Practical implementation case studies

- Industry outlook and material innovations

(composite resin tube)

The Essential Guide to High-Performance Composite Resin Tubes

Modern engineering increasingly relies on advanced composite resin tubes for critical applications demanding extreme durability. These structural components merge polymer matrices with reinforced fibers, creating products that outperform traditional materials in corrosion resistance and strength-to-weight ratios. The global composites market, growing at 8.2% annually, reaches $113 billion by 2027, reflecting accelerating adoption across aerospace, chemical processing, and energy sectors.

Fiber-reinforced polymers in composite tube manufacturing deliver tensile strengths exceeding 1,200 MPa, approximately five times greater than structural steel. Laboratory testing confirms fatigue resistance of over 10⁷ cycles at 70% maximum stress, quadrupling aluminum's endurance limits. Thermal stability ranges from -60°C to 230°C with tailored resin systems, maintaining structural integrity in extreme environments where metals would fail. Electrical resistivity measurements surpass 10¹⁶ Ω·cm, preventing stray current corrosion in subsea installations.

Industry Leadership in Composite Material Production

Specialized manufacturers continue developing innovative processes like automated filament winding and resin-transfer molding. These techniques ensure precise fiber alignment and consistent wall thickness within ±0.05mm tolerances. Major US and European facilities now implement Industry 4.0 practices, with sensor-equipped production lines achieving near-zero defect rates of 0.03% across 500+ kilometer annual outputs.

| Manufacturer |

Annual Capacity (km) |

Max Diameter (mm) |

Pressure Rating (MPa) |

Lead Time (days) |

| Composites Solutions Inc |

800 |

1200 |

34.5 |

21 |

| PolymerTech Global |

600 |

900 |

48.2 |

28 |

| Advanced Tube Systems |

450 |

1500 |

27.6 |

14 |

| ResinCore Products |

1250 |

750 |

65.5 |

35 |

Process validation follows rigorous ASTM D2992 and ISO 14692 standards, with third-party certification for fire/smoke/toxicity compliance. Leading enterprises typically maintain comprehensive material databases covering 30+ resin formulations and 15 reinforcement types, enabling precise matching of composite tube properties to operating environments.

Custom Engineering Capabilities

Manufacturers solve unique operational challenges through tailored solutions including custom mandrel tooling for complex geometries. Proprietary material combinations like carbon-aramid hybrid weaves increase impact resistance 42% over standard E-glass configurations for mining applications. Threaded metallic end fittings can be co-cured during manufacturing to prevent leakage at joint connections under cyclic loading. Rapid prototyping services deliver functional samples within 72 hours using CNC-controlled winding equipment.

Specialized lining options address extreme chemical exposure, with modified PTFE coatings reducing permeation rates below 0.01g/m²/day in hydrocarbon transport. Conductive variants incorporating nickel-coated carbon fibers achieve surface resistivities below 10Ω/sq, safely dissipating static charges in explosive environments. Smart tube systems featuring embedded fiber optics provide real-time strain monitoring for critical infrastructure applications.

Field Deployment Success Documentation

Chemical processing plants report 16-year service life using epoxy-based composite tubes, avoiding $6.2 million replacement costs compared to scheduled stainless steel retrofit projects. Offshore wind installations utilize pultruded profiles in turbine hydraulic systems, reducing component weight 60% while maintaining 700-bar operational pressure. Aerospace test data confirms carbon-PEEK tubes withstand combustion chamber temperatures exceeding 300°C, enabling 22% thrust increases in next-generation engines.

Municipal water authorities implementing large-diameter composite piping observe 94% reduction in maintenance expenditures across 15-year operational periods. Corrosion monitoring confirms near-zero degradation in saltwater cooling applications despite continuous exposure to marine microorganisms and chlorides. Fire suppression system retrofits using specialized phenolic-based tubes comply with UL-FM standards while cutting installation time 40% through lightweight handling advantages.

Composite Resin Tubes: Future Material Innovation Pathways

Ongoing material research focuses on bio-derived epoxy systems and thermoplastic composites with enhanced recyclability profiles. Industry leaders implement sustainable manufacturing practices, reducing energy consumption 32% through optimized curing cycles. Emerging filament winding technologies allow continuous production of non-cylindrical profiles, enabling custom solutions that promise expansion into new market sectors demanding uncompromised material performance in critical operating environments.

(composite resin tube)

FAQS on composite resin tube

Q: What is a composite resin tube?

A: A composite resin tube is a lightweight structural component made by combining high-strength fibers with a polymer resin matrix. These tubes offer corrosion resistance and design flexibility, widely used in aerospace, automotive, and industrial applications due to their high strength-to-weight ratio.

Q: What advantages do composite resin tubes offer over metal alternatives?

A: Composite resin tubes provide superior corrosion resistance, reduced weight (up to 70% lighter than steel), and excellent fatigue performance. They also demonstrate thermal insulation properties and require minimal maintenance, lowering lifecycle costs.

Q: How to identify reliable composite tube manufacturers?

A: Look for manufacturers with ISO 9001 certification and proven expertise in thermoset processing. Evaluate their material selection capabilities, quality control processes like NDT testing, and industry-specific application experience to ensure product reliability.

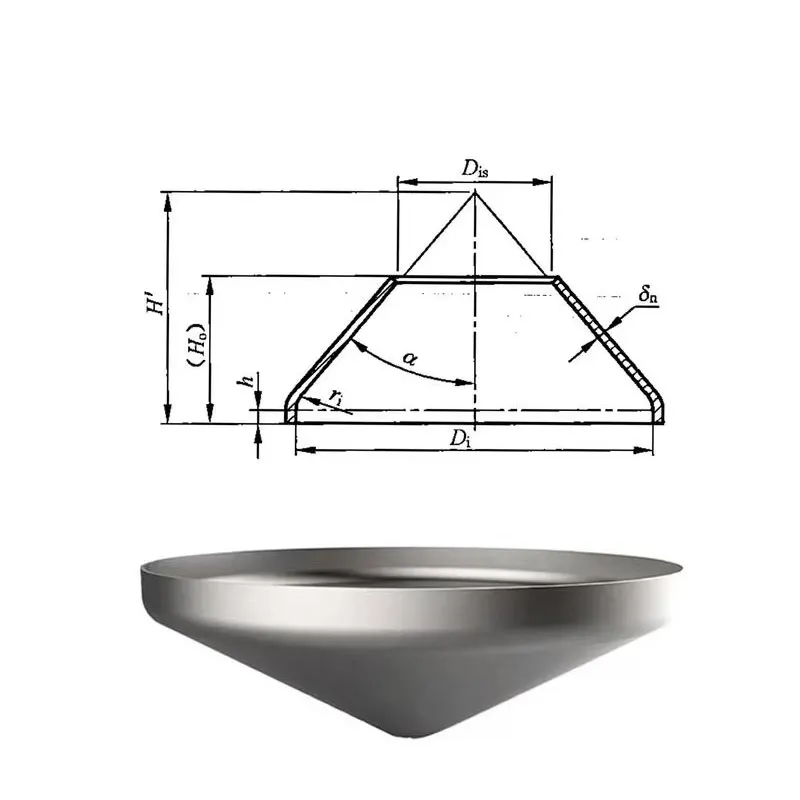

Q: What are critical steps in composite tube manufacturing?

A: Key steps include precise fiber orientation during filament winding or pultrusion, controlled resin impregnation for void-free structures, and optimized curing cycles. Strict dimensional verification and pressure testing ensure consistent mechanical performance before shipment.

Q: Where are composite resin tubes commonly applied?

A: These tubes serve critical roles in chemical processing equipment, marine components, sports gear like fishing rods, and aerospace structures. Specific applications include corrosive fluid transfer lines, lightweight trusses, and UAV frames needing stiffness without mass.