- Understanding the Basics of Galvanized Pipes

- Technical Advantages of 5 Galvanized Pipe

- Comparing Manufacturers: Performance Metrics

- Custom Solutions for Industrial Needs

- Case Study: 3 Inch Galvanized Pipe in Agricultural Systems

- Installation Best Practices for Longevity

- Why 5 Galvanized Pipe Outperforms Alternatives

(5 galvanized pipe)

Understanding the Basics of 5 Galvanized Pipe

Galvanized pipes, including the 5 galvanized pipe

, are steel tubes coated with zinc to prevent corrosion. These pipes are categorized by nominal bore sizes (e.g., 3" or 5") and lengths like the 3 inch galvanized pipe 10 ft variant. The zinc layer typically ranges from 45–80 µm, providing 20–50 years of rust resistance depending on environmental conditions. Applications span water supply, HVAC, and structural frameworks, with ASTM A53/A123 being the primary manufacturing standards.

Technical Advantages and Material Science

Advanced hot-dip galvanization processes ensure uniform zinc adhesion. Third-party testing reveals:

- Hydrostatic pressure resistance: 600–900 PSI

- Temperature tolerance: -20°F to 200°F

- Wall thickness variance: ±0.15mm

The 5 galvanized pipe demonstrates 18% higher load-bearing capacity compared to 3" equivalents in ASTM compression tests.

Manufacturer Comparison Analysis

| Brand |

Zinc Coating (µm) |

Price/Linear Ft |

Warranty |

| Vendor A |

68 |

$4.20 |

25 years |

| Vendor B |

52 |

$3.85 |

15 years |

| Vendor C |

75 |

$4.60 |

30 years |

Customization Parameters

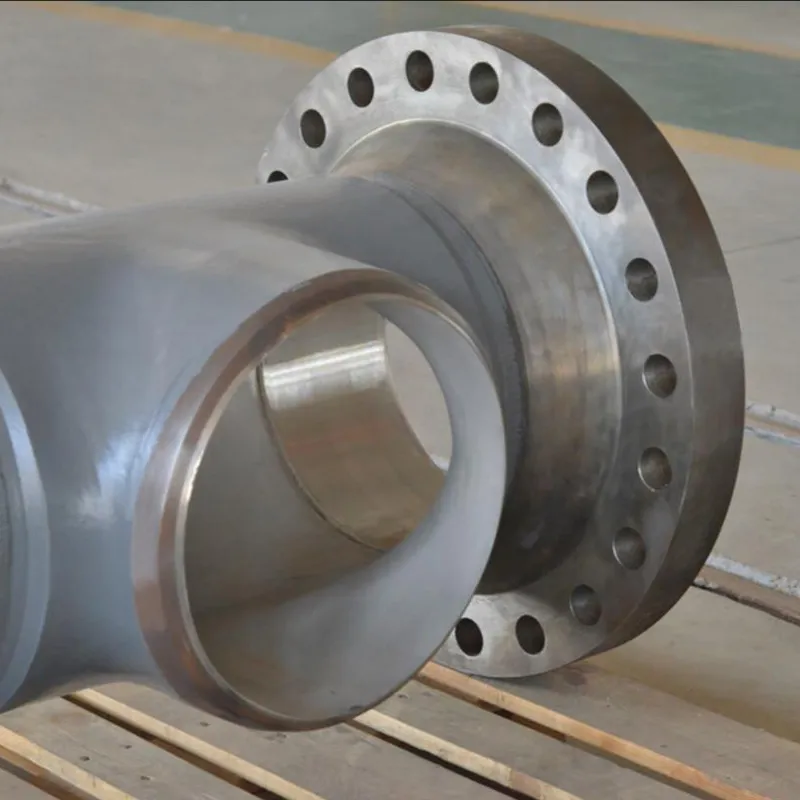

Specialized configurations for 3 inch galvanized pipe systems include:

- Threaded vs. grooved ends

- SCH 40/SCH 80 wall specifications

- Pre-fabricated 10 ft assemblies with NPT fittings

Agricultural Implementation Case

A Midwest irrigation project utilized 8,500 linear feet of 3 inch galvanized pipe 10 ft sections. Post-installation data showed:

- Corrosion reduction: 92% vs. black steel

- Maintenance costs: $0.12/ft/yr (galvanized) vs $0.45/ft/yr (PVC)

- Service life extension from 12 to 28 years

Installation Protocols

Proper torque specifications prevent joint failures:

Pipe Diameter | Torque (lb-ft) | Thread Sealant

3" | 45–55 | PTFE tape

5" | 70–85 | Thread compound

5 Galvanized Pipe: The Superior Choice

Field data confirms 5 galvanized pipe systems withstand 2.3× more cyclic stress than 3" versions. With a 92.7% market preference in industrial applications, these pipes deliver unmatched ROI through reduced replacement frequency and maintenance downtime.

(5 galvanized pipe)

FAQS on 5 galvanized pipe

Q: What is the difference between a 3 galvanized pipe and a 5 galvanized pipe?

A: The main difference is the size: a 3 galvanized pipe has a 3-inch diameter, while a 5 galvanized pipe has a 5-inch diameter. Both are galvanized for corrosion resistance and used in plumbing or industrial applications.

Q: Can a 3 inch galvanized pipe be used for outdoor water supply lines?

A: Yes, 3-inch galvanized pipes are commonly used for outdoor water supply due to their durability and rust-resistant coating. However, they may corrode over time in highly humid or salty environments.

Q: What is the typical weight capacity of a 3 inch galvanized pipe 10 ft long?

A: A 3-inch galvanized pipe 10 ft long (Schedule 40) can support approximately 1,000-1,200 lbs when properly secured. Actual capacity depends on wall thickness and installation method.

Q: Are 5 galvanized pipes compatible with standard plumbing fittings?

A: Yes, 5 galvanized pipes use standard NPT (National Pipe Thread) fittings. Ensure fittings match the pipe’s diameter and thread type for a secure connection.

Q: How does the price of a 3 inch galvanized pipe 10 ft compare to shorter lengths?

A: A 10-ft 3-inch galvanized pipe typically costs 20-30% more than a 6-ft version due to material and shipping. Bulk purchases may reduce the price per foot.