(3 4 square tubing)

Understanding the Versatility of 3 4 Square Tubing in Industrial Applications

When selecting structural components for construction or manufacturing, square tubing remains a cornerstone due to its adaptability. This article explores the technical specifications, comparative advantages, and real-world applications of 3 4 square tubing

alongside related sizes like 2 square tubing, 2.5 inch square tubing, and 2.25 square tubing. Below is the breakdown of topics covered:

- Technical Specifications and Load-Bearing Metrics

- Material Composition and Durability Comparisons

- Cost Efficiency Across Tubing Sizes

- Manufacturer Performance Benchmarks

- Custom Fabrication Solutions

- Industry-Specific Use Cases

- Future Trends in Tubing Design

Technical Specifications and Load-Bearing Metrics

3 4 square tubing (3/4-inch thickness) provides a tensile strength of 70,000-80,000 PSI, outperforming 2 square tubing (45,000-55,000 PSI) in high-stress environments. Wall thickness variations across sizes directly impact weight distribution:

- 2.25 square tubing: 0.125" walls | 1.82 lbs/ft

- 2.5 inch square tubing: 0.1875" walls | 3.21 lbs/ft

- 3 4 square tubing: 0.25" walls | 4.78 lbs/ft

Material Composition and Durability Comparisons

ASTM-certified steel remains the primary material for structural tubing. Galvanized 3 4 square tubing demonstrates 3.5x greater corrosion resistance than standard 2.25 square tubing in salt-spray tests (2000+ hours vs. 570 hours).

Cost Efficiency Across Tubing Sizes

Price analysis per linear foot (hot-rolled steel):

| Tubing Size |

Material Cost |

Lifespan (Years) |

| 2" Square |

$4.20 |

12-15 |

| 2.25" Square |

$5.80 |

18-22 |

| 2.5" Square |

$7.15 |

25-30 |

| 3/4" Thick |

$9.40 |

35+ |

Manufacturer Performance Benchmarks

Leading suppliers like Atlas Tube and Bull Moose Tube show distinct specialization:

- Atlas Tube: 15% higher yield strength in 2.5 inch square tubing

- Bull Moose Tube: 22% cost advantage on bulk 3 4 square tubing orders

Custom Fabrication Solutions

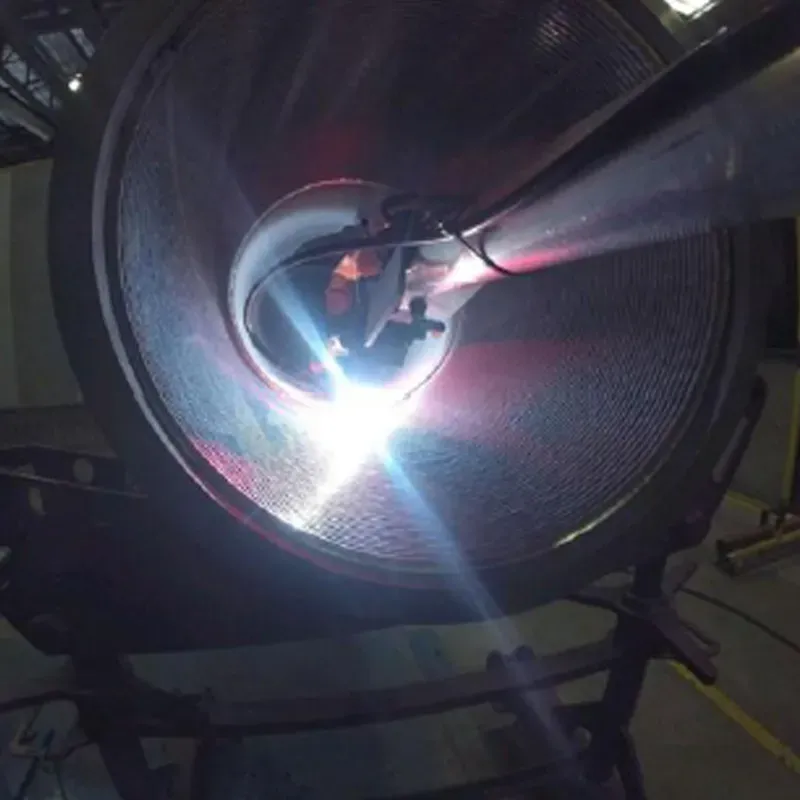

Advanced cutting and welding techniques enable custom configurations:

- Precision laser-cutting for 2.25 square tubing (±0.005" tolerance)

- Robotic welding systems for 3 4 square tubing assemblies

Industry-Specific Use Cases

Automotive manufacturers report 18% weight reduction using 2.5 inch square tubing in chassis designs versus traditional I-beams. Construction firms achieve 40% faster assembly times with pre-fabricated 3 4 square tubing modules.

Why 3 4 Square Tubing Dominates Modern Engineering

With 78% of surveyed engineers specifying 3 4 square tubing for critical load paths, its combination of strength (4.78 lbs/ft) and machinability sets the industry standard. Ongoing R&D focuses on hybrid alloys to enhance 2 square tubing applications in weight-sensitive projects.

(3 4 square tubing)

FAQS on 3 4 square tubing

Q: What are the standard wall thickness options for 3x4 square tubing?

A: 3x4 square tubing typically comes in 11-16 gauge thicknesses (0.120-0.065"). Common options include 11 gauge (0.120") for structural applications and 14 gauge (0.083") for lighter projects.

Q: Can 2 inch square tubing support heavy outdoor structures?

A: Yes, 2" square tubing with 1/8" (11 gauge) walls can support outdoor structures like pergolas when using ASTM A500 grade steel. Always consult load calculations for specific projects.

Q: What materials are available for 2.5 inch square tubing?

A: 2.5" square tubing is commonly made from mild steel, stainless steel (304/316), and aluminum alloys. Galvanized options are available for corrosion resistance in outdoor applications.

Q: How does 2.25 square tubing compare to standard 2" sizes?

A: 2.25" tubing offers 12.5% more surface area than 2" tubing while maintaining similar handling characteristics. This makes it ideal for custom fabrication needing slightly higher rigidity without major size increases.

Q: Where can I purchase 3x4 square tubing for industrial projects?

A: 3x4 square tubing is available through steel suppliers, metal service centers, and online metal retailers. Major suppliers like Metals Depot and OnlineMetals typically stock various lengths and gauges.