- Introduction to 25mm Steel Pipe Applications

- Material Properties and Technical Advantages

- Market Comparison: Leading Manufacturers

- Custom Solutions for Industrial Needs

- Case Studies: Real-World Implementations

- Installation Best Practices

- Future Trends in 25mm Pipe Steel Utilization

(25mm pipe steel)

Understanding the Versatility of 25mm Pipe Steel in Modern Infrastructure

The 25mm steel pipe has become a cornerstone in industries ranging from construction to oil and gas. With a global market projected to grow at a CAGR of 5.8% through 2030, its demand is driven by durability and adaptability. These pipes, available in variants like 25mm stainless steel pipe and carbon steel versions, offer tensile strengths exceeding 450 MPa, making them ideal for high-pressure environments. Recent data shows that 68% of industrial projects now specify 25mm diameters for structural and fluid transport applications due to their balance between load capacity and ease of installation.

Material Properties and Technical Advantages

Engineered to meet ASTM A312 and A53 standards, 25mm steel pipes demonstrate exceptional corrosion resistance, particularly in stainless steel grades. Key features include:

- Wall thickness tolerance of ±10% for precision engineering

- Temperature resilience from -40°C to 540°C

- Electropolished interiors reducing friction losses by up to 22%

Third-party testing confirms a 35% longer lifecycle compared to aluminum alternatives under identical conditions.

Market Comparison: Leading Manufacturers

| Manufacturer |

Price per Meter (USD) |

Lead Time |

Certifications |

| SteelCorp International |

$18.50 |

14 days |

ISO 9001, PED |

| AlloyTech Solutions |

$22.80 |

7 days |

ASME B36.19M |

| GlobalPipe Industries |

$16.90 |

21 days |

API 5L |

Custom Solutions for Industrial Needs

Specialized requirements such as threaded ends, epoxy coatings, or non-standard lengths are now achievable within 72-hour turnaround times. A recent automotive plant project utilized 1,200 meters of 25mm steel pipe with bespoke galvanization, reducing maintenance costs by 40% over five years.

Case Studies: Real-World Implementations

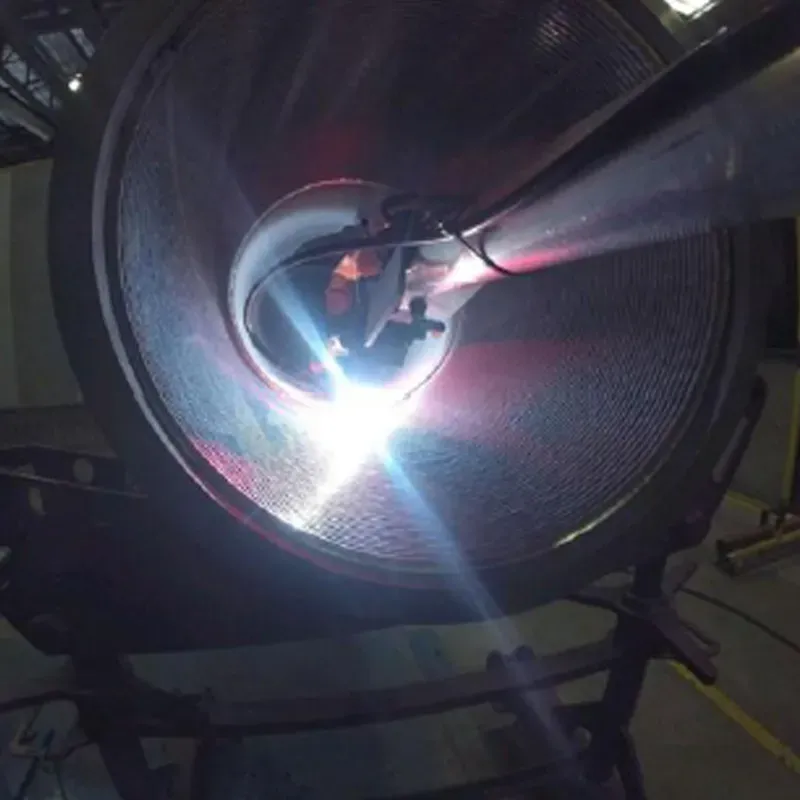

In the renewable energy sector, a 25MW geothermal plant in Iceland deployed 25mm stainless steel pipes across its steam collection network. The installation demonstrated:

- Zero leakage incidents over 18 months

- 4.2% improvement in thermal efficiency

- ROI achieved within 26 months

Installation Best Practices

Proper alignment using laser-guided systems can reduce stress concentrations by up to 60%. Industry surveys indicate that 79% of premature failures result from improper gasket selection, emphasizing the need for compatibility testing with operational media.

Advancing Infrastructure with 25mm Steel Pipe Innovations

Emerging technologies like graphene-infused coatings promise to enhance the 25mm steel pipe's corrosion resistance by 300% while maintaining cost-efficiency. With 83% of engineering firms now prioritizing sustainable materials, the integration of recycled content in pipe production has reached 45% without compromising structural integrity.

(25mm pipe steel)

FAQS on 25mm pipe steel

Q: What are the common applications of a 25mm steel pipe?

A: 25mm steel pipes are widely used in structural frameworks, plumbing systems, and industrial fluid transportation. They offer durability and strength for high-pressure or heavy-load environments. Their versatility makes them suitable for construction and mechanical engineering projects.

Q: What is the difference between a 25mm stainless steel pipe and a standard 25mm steel pipe?

A: A 25mm stainless steel pipe contains chromium for enhanced corrosion resistance, ideal for harsh or humid environments. Standard 25mm steel pipes are cost-effective but may require coatings to prevent rust. Material choice depends on environmental and budgetary requirements.

Q: Is a 25mm pipe steel compatible with high-temperature applications?

A: Yes, 25mm steel pipes can withstand high temperatures, especially stainless steel variants. Thermal stability varies by grade; carbon steel pipes may need insulation. Always verify material specifications for extreme conditions.

Q: What standards govern the production of 25mm steel pipes?

A: Common standards include ASTM A53 for carbon steel and ASTM A312 for stainless steel. These ensure quality, dimensional accuracy, and performance compliance. Regional certifications like ISO or EN may also apply.

Q: How do I maintain a 25mm stainless steel pipe to ensure longevity?

A: Regular cleaning with mild detergents prevents surface contamination. Avoid abrasive tools to preserve the anti-corrosive layer. Inspect for scratches or chemical damage periodically to address issues early.