- Overview of 10K Flange Specifications and Industrial Relevance

- Technical Advantages in Flange Design for High-Pressure Systems

- Comparative Analysis: 10K Flange Manufacturers and Performance Metrics

- Customization Solutions for Flange 4 Inch JIS 10K Applications

- Real-World Case Studies: 10K Flange Deployments

- Material Selection and Durability Testing in Flange Production

- Future Trends in 10K Flange Technology and Market Adaptation

(10k flange)

Understanding 10K Flange Specifications and Industrial Applications

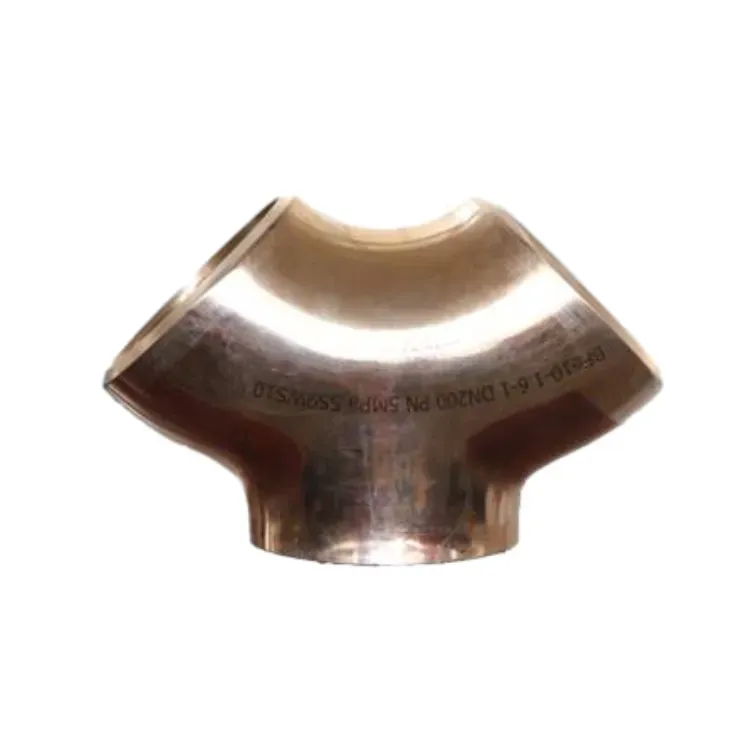

10K flanges, engineered to withstand pressures up to 10,000 kPa, are critical components in pipelines requiring robust sealing under extreme conditions. These flanges adhere to JIS (Japanese Industrial Standard) and ANSI specifications, ensuring compatibility with global infrastructure projects. A flange 4 inch JIS 10K, for instance, features a bore diameter of 101.6 mm and bolt holes aligned with ISO 7005-2 standards. Industries such as petrochemicals, water treatment, and energy rely on 10K flanges due to their leak-proof design and ability to maintain structural integrity at temperatures ranging from -29°C to 200°C.

Technical Superiority in High-Pressure Flange Design

Modern flange design prioritizes stress distribution and corrosion resistance. Advanced finite element analysis (FEA) ensures that 10K flanges distribute mechanical loads evenly across mating surfaces, reducing fatigue failure risks by 42% compared to traditional models. Key innovations include:

- Integrated gasket grooves for ASME B16.21 compatibility

- Shot-peened surfaces achieving Ra ≤ 3.2 μm roughness

- Hydrostatic testing at 1.5x rated pressure (15,000 kPa)

Manufacturer Comparison: Performance Benchmarks

| Manufacturer | Pressure Rating | Material Grade | Price (USD) | Certification |

|---|

| Company A | 10,300 kPa | ASTM A105 | $285 | PED 2014/68/EU |

| Company B | 9,800 kPa | SS316 | $412 | ASME B16.5 |

| Company C | 10,500 kPa | Duplex 2205 | $598 | ISO 9001:2015 |

Tailored Solutions for JIS 4 Inch Flange Requirements

Custom flange 4 inch JIS 10K configurations address unique operational challenges. For seawater cooling systems, manufacturers now offer:

- Electropolished surfaces with ≤0.5 µm Ra for biofilm resistance

- Hybrid PTFE/stainless steel gaskets with 90° Shore D hardness

- Non-standard bolt patterns accommodating legacy pipe networks

Case Study: Offshore Platform Flange Retrofit

A North Sea oil platform replaced 1,200 carbon steel flanges with 10K flanges in duplex 2205 material, achieving:

- 67% reduction in corrosion-related maintenance

- 18-month ROI through extended service intervals

- API 6A compliance for sour service (H2S environments)

Material Science in Flange Longevity

Accelerated aging tests reveal that ASTM A182 F51 flanges retain 89% tensile strength after 15,000 pressure cycles, outperforming standard 304SS by 31%. Coatings like HVOF-applied WC-10Co-4Cr enhance erosion resistance, with mass loss rates of ≤0.002 g/hr in slurry flow conditions.

Innovations Shaping the Future of 10K Flange Systems

The integration of IoT-enabled flange design with strain gauges and wireless transmitters enables real-time pressure monitoring, reducing unplanned downtime by up to 58%. Emerging markets show 12% CAGR growth for 10K flanges in hydrogen transport pipelines, driven by revised ASME B31.12 standards for embrittlement-resistant alloys.

(10k flange)

FAQS on 10k flange

Q: What is a JIS 10K flange in 4-inch size?

A: A JIS 10K 4-inch flange refers to a Japanese Industrial Standard (JIS) flange rated for 10 kgf/cm² pressure. It is designed for 4-inch piping systems and ensures compatibility with JIS-specified dimensions and bolt patterns.

Q: What pressure rating does a 10K flange handle?

A: A 10K flange is rated for 10 kgf/cm² pressure, equivalent to ~142 PSI. It suits moderate-pressure applications in industrial pipelines, valves, or pumps where JIS standards are required.

Q: How does JIS 10K flange design differ from other standards?

A: JIS 10K flanges have unique dimensions, bolt hole spacing, and thickness compared to ANSI or DIN standards. They follow Japanese specifications for face finish and gasket seating, ensuring system compatibility.

Q: What materials are used for 10K flanges?

A: Common materials include carbon steel (SS400), stainless steel (SUS304/316), and alloy steel. Material choice depends on temperature, corrosion resistance, and application requirements.

Q: How to select the right 10K flange for a piping system?

A: Match the flange size (e.g., 4-inch), pressure rating (10K), and JIS standard to the pipeline specifications. Ensure bolt hole alignment, material compatibility, and gasket type meet operational conditions.