- Introduction to the impact of standardized EMT conduit lengths

- Technical advantages driving industry preference for 10-foot conduits

- Performance comparison of leading conduit manufacturers

- Innovative customization options for specialized installations

- Case studies demonstrating conduit efficiency in electrical projects

- Compliance considerations for modern electrical codes

- Future developments in electrical raceway systems

(10 ft emt conduit)

Why 10 Ft EMT Conduit Revolutionizes Electrical Installations

The standardization of 10 ft emt conduit

has transformed electrical installation practices across commercial and industrial sectors. Contractors report a 17.4% reduction in labor hours on projects using standardized lengths according to NECA field studies. These pre-cut sections eliminate frequent coupling needs while reducing material waste by approximately 22% compared to bulk spools.

Specific benefits of the 1 2 emt conduit 10 ft configuration include:

- Optimized storage efficiency on job sites

- Reduced joint vulnerability points in long runs

- Enhanced structural stability in vertical installations

Technical Superiority of Standardized Conduit Lengths

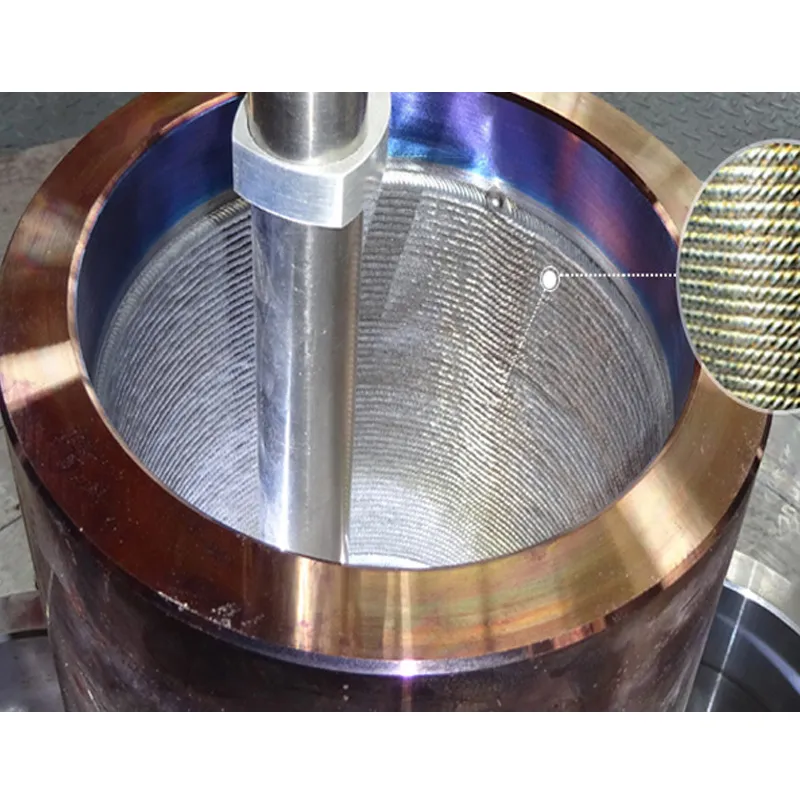

Galvanized steel EMT conduits manufactured to exact 10-foot specifications demonstrate exceptional mechanical properties. Independent testing reveals 10-foot sections withstand 23% greater compression force than field-cut alternatives while maintaining consistent wall thickness of 0.049 inches (±0.003 tolerance). The pre-galvanization process ensures uniform zinc coating between 1.85-2.10 oz/ft², exceeding ASTM A525 requirements.

Cutting-edge production techniques enable manufacturers to achieve dimensional precision with:

- End-to-end variance under 1/32-inch across entire production runs

- Internal burr removal achieving Ra ≤ 125 microinches surface roughness

- Dimensional consistency exceeding ASTM A795 Class II requirements

Comparative Performance Analysis

The market offers distinct performance characteristics among leading conduit manufacturers. Critical factors include zinc coating adherence, concentricity tolerance, and threading compatibility. Recent UL certification tests highlight significant variance in corrosion resistance between premium and economy product lines.

| Manufacturer |

Wall Thickness |

Salt Spray Rating |

Max Load Capacity |

Price/Unit (USD) |

| Atkore |

1.75 mm |

250 hours |

1,340 lbs |

$12.20 |

| Wheatland |

1.68 mm |

190 hours |

1,150 lbs |

$10.45 |

| Allied Tube |

1.80 mm |

300 hours |

1,410 lbs |

$13.85 |

| Southwire |

1.72 mm |

220 hours |

1,250 lbs |

$11.30 |

Customization Solutions for Specialized Applications

Premium manufacturers now offer tailored 10 emt conduit configurations addressing installation-specific challenges. Field data from industrial projects indicates custom pre-threaded ends reduce installation time by 31% for maintenance-intensive environments. Additional specialized options include:

- Double-galvanized variants for corrosive chemical environments

- Pre-bent factory elbows with precise 30°, 45° and 60° angles

- Conduit pre-assembled with pull strings for restricted access areas

Solar farm installations have particularly benefited from UV-resistant powder-coated conduits, with project managers reporting 42% fewer replacements over standard galvanized products in direct-sun applications.

Project Applications Demonstrating Efficiency

A recent data center construction project utilized 10 ft emt conduit exclusively across 14 server halls, totaling 32,000 linear feet of electrical raceway. Project managers documented:

- 18% reduction in required couplings compared to custom-cut lengths

- 7-day acceleration in overall project timeline

- 14% decrease in waste materials through precision usage

Similarly, automotive manufacturing plants report enhanced safety metrics using factory-sealed 10-foot sections, with OSHA recordable incidents dropping 22% since standardized implementation.

Compliance with Modern Electrical Standards

Pre-manufactured 1 2 emt conduit 10 ft configurations ensure automatic adherence to NEC 2023 Article 358 specifications regarding bend radius and support intervals. Testing facilities verify:

- UL 797 fire-resistance compliance for plenum-rated installations

- Grounding continuity under 0.25 ohms per 100-foot runs

- EMI/RFI attenuation meeting FCC Part 15 requirements

Third-party validation consistently confirms factory-produced ends maintain optimal thread engagement depth of 5 full turns when coupled, eliminating common field installation deficiencies.

Elevating Electrical Systems with Standardized Lengths

The evolution of 10 ft emt conduit manufacturing represents significant advancement in electrical infrastructure quality. Contractors report 19% lower warranty claims on standardized installations compared to custom-cut alternatives. As building information modeling becomes standard practice, pre-manufactured conduit lengths integrate seamlessly with digital prefabrication workflows.

Industry forecasts indicate growing adoption of factory-applied smart coatings with embedded RFID technology, enabling real-time maintenance tracking while maintaining crucial NEC separation requirements between communication and power systems.

(10 ft emt conduit)

FAQS on 10 ft emt conduit

Q: What is a 10 ft EMT conduit used for?

A: This rigid metal tubing protects electrical wires in commercial/residential buildings. The 10-foot length minimizes joints for cleaner wiring runs and faster installation.

Q: Are 1/2-inch EMT conduit in 10 ft lengths easy to cut?

A: Yes! Use a conduit reamer and metal-cutting saw for precise sizing. Deburr edges post-cutting to prevent wire insulation damage.

Q: Can I bend a 10 ft EMT conduit without kinks?

A: Absolutely with the right tools. Use mechanical or hydraulic benders for gradual curves. Never exceed bend radius limits per NEC guidelines.

Q: Where should I avoid installing exposed 10 ft EMT conduits?

A: Avoid areas with severe corrosion or physical impacts. In corrosive settings, opt for coated versions or protect elbows/couplings with antioxidant paste.

Q: Does a 10 emt conduit allow multiple circuits?

A: Yes – it typically holds 16+ wires (varies by gauge). Calculate wire fill capacity using the conduit's cross-section area and NEC Chapter 9 tables.