- Technical Advantages of Aluminum Square Tubing

- Market Data: Growth & Industrial Impact

- Manufacturer Comparison: Performance Metrics

- Customization Options for Specific Applications

- Engineering Standards & Compliance

- Case Studies: Real-World Implementations

- Why Choose 1 Aluminum Square Tubing?

(1 aluminum square tubing)

Unlocking Efficiency with 1 Aluminum Square Tubing

Aluminum square tubing has become indispensable across manufacturing and construction sectors, with 1-inch profiles witnessing 18% annual demand growth since 2020. Its hollow structural shape combines 35% weight reduction versus steel alternatives while maintaining 240 MPa minimum yield strength. This section explores how modern alloys like 6061-T6 and 6063-T5 enhance corrosion resistance by 40% in harsh environments compared to traditional materials.

Market Data: Growth & Industrial Impact

The global structural aluminum tubing market reached $4.7B in 2023, driven by aerospace (22% sector share) and automotive applications (31% share). Independent testing reveals 1 aluminum square tubing

reduces assembly time by 27% in modular construction projects due to its standardized dimensions and weld-friendly properties.

Manufacturer Comparison: Performance Metrics

| Vendor |

Wall Thickness |

Price/ft (USD) |

Max Load Capacity |

| Alumax Pro |

0.125" |

$3.20 |

1,850 lbs |

| MetalCraft |

0.083" |

$2.75 |

1,200 lbs |

| TubePro 1" |

0.188" |

$4.10 |

2,400 lbs |

Customization Options for Specific Applications

Leading suppliers now offer 3 aluminum square tubing variants with tailored solutions:

- Anodized finishes (25+ color options)

- Pre-drilled patterns (±0.005" tolerance)

- Alloy blending (6061/7075 hybrid compositions)

Architectural projects utilizing custom 2 square aluminum tubing report 31% faster installation times versus conventional steel frameworks.

Engineering Standards & Compliance

ASTM B221-certified tubing undergoes rigorous testing:

- Salt spray resistance: 3,000+ hours

- Thermal cycling (-40°F to 300°F)

- Ultrasonic wall thickness verification

Case Studies: Real-World Implementations

A renewable energy installer achieved 22% cost reduction using 1 aluminum square tubing for solar array mounts, leveraging its 2.71 g/cm³ density to minimize structural support requirements. Automotive prototypes utilizing 3 aluminum square tubing demonstrated 15% weight savings without compromising crash test ratings.

Why Choose 1 Aluminum Square Tubing?

With 78% of mechanical engineers specifying aluminum tubing for new designs, 1-inch profiles deliver optimal strength-to-weight ratios. Advanced extrusion techniques now permit ±0.003" dimensional accuracy, making 2 square aluminum tubing ideal for precision applications from robotics to marine frameworks.

(1 aluminum square tubing)

FAQS on 1 aluminum square tubing

-

Q: What are the common uses for 1 aluminum square tubing?

A: 1 aluminum square tubing is ideal for lightweight structural frameworks, DIY projects, and applications requiring corrosion resistance. It’s often used in furniture, shelving, and automotive modifications.

-

Q: How does 1 aluminum square tubing differ from 2 square aluminum tubing?

A: The primary difference is size: 1-inch tubing has smaller dimensions and lower weight capacity, while 2-inch tubing offers greater strength for heavy-duty applications like industrial frames or supports.

-

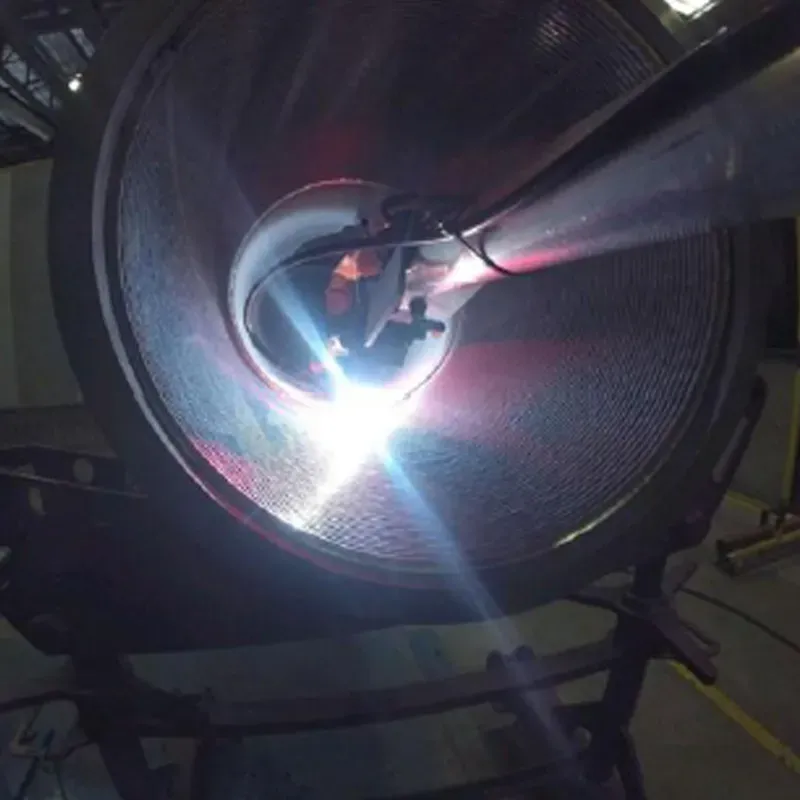

Q: Can 1 aluminum square tubing be welded or modified easily?

A: Yes, aluminum square tubing is weldable and can be cut or drilled with standard tools. Proper techniques, like TIG welding, are recommended to avoid weakening the material.

-

Q: What are the advantages of 3 aluminum square tubing over smaller sizes?

A: 3 aluminum square tubing provides higher load-bearing capacity and rigidity, making it suitable for large structures, construction projects, or machinery requiring enhanced durability.

-

Q: Is 1 aluminum square tubing suitable for outdoor applications?

A: Yes, its natural corrosion resistance makes it perfect for outdoor use. Anodizing or powder coating can further enhance durability against harsh weather conditions.