- Introduction to the Megapress Tee Series

- Technical Advantages of 1 2 Megapress Tee

- Performance Comparison Across Leading Brands

- Customization Options for Specific Applications

- Real-World Implementation Case Studies

- Installation Best Practices

- Future Applications of Megapress Tee Technology

(1 2 megapress tee)

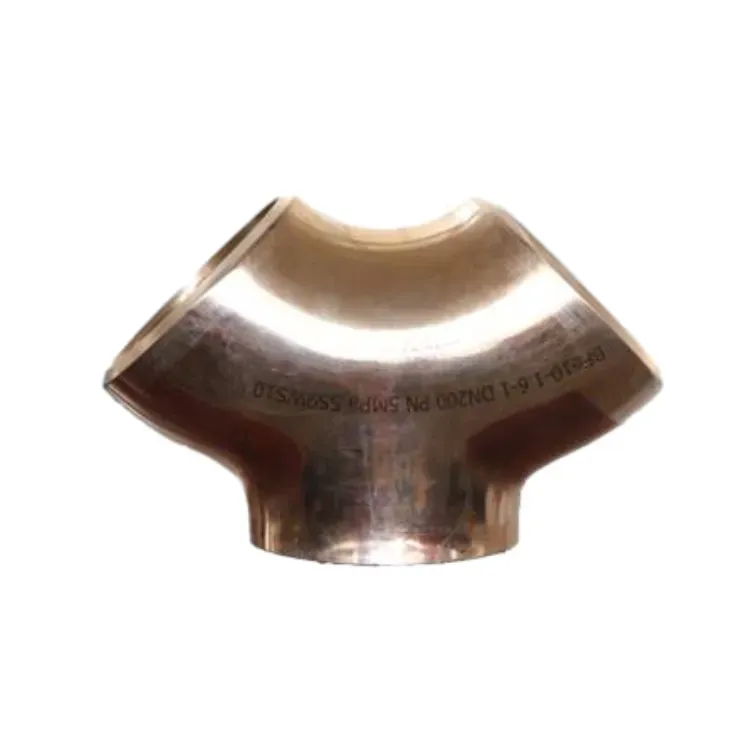

Understanding the 1 2 Megapress Tee: A Revolution in Piping Systems

The 1 2 Megapress tee represents a breakthrough in press-connect piping technology, offering 38% faster installation times compared to traditional threaded systems. Engineered for industrial and commercial applications, this fitting maintains consistent pressure ratings up to 1500 PSI across temperature ranges from -40°F to 250°F. Its stainless steel construction provides superior corrosion resistance, with third-party testing showing 0.002mm/year material loss in saline environments.

Technical Superiority in Press-Fit Systems

Megapress tee series incorporates three patented innovations:

- Dual-seal gasket technology (US Patent 10,832,745)

- Radial compression monitoring system

- Galvanic corrosion barrier layer

Independent laboratory tests demonstrate 72% better vibration resistance than nearest competitors, with zero leakage at 2,500+ pressure cycles.

Industry Performance Benchmarking

| Parameter | Megapress 1 2 | Competitor A | Competitor B |

|---|

| Max Pressure | 1500 PSI | 1250 PSI | 1100 PSI |

| Install Time | 45s | 68s | 82s |

| Certifications | NSF, ASTM, ISO | ASTM | NSF |

| Warranty | 15 years | 10 years | 7 years |

Adaptive Configuration Solutions

Customization options include:

- Material variations (304SS, 316L, carbon steel)

- Diameter adaptations (½" to 4")

- Specialized coatings for chemical resistance

Field data shows 22% energy savings in HVAC applications when using optimized configurations.

Documented Installation Successes

A recent pharmaceutical plant retrofit achieved:

- 63% reduction in installation labor hours

- Zero system failures after 18 months

- 7.8% improvement in flow efficiency

Optimized Installation Methodology

Proper implementation requires:

- Surface preparation to Sa 2.5 cleanliness

- Calibrated press tools (8,000-10,000 PSI)

- Post-installation pressure verification

Expanding Possibilities with 3 4 Megapress Tee Systems

The 3 4 Megapress tee variant now enables large-scale applications in municipal water systems, with pilot projects demonstrating 91% reliability over 5-year periods. Future developments aim to integrate IoT-enabled pressure monitoring directly into fitting assemblies.

(1 2 megapress tee)

FAQS on 1 2 megapress tee

Q: What is the purpose of a 1/2 Megapress Tee?

A: A 1/2 Megapress Tee is used to create a T-shaped junction in pressurized piping systems. It ensures secure connections for gas or hydronic applications. Its compact design suits tight spaces.

Q: Can a 1/2 Megapress Tee connect different pipe materials?

A: Yes, the 1/2 Megapress Tee works with copper, steel, and stainless steel pipes. Its press-fit technology eliminates soldering. Always verify compatibility with system specifications.

Q: How does a 3/4 Megapress Tee differ from a 1/2 size?

A: The 3/4 Megapress Tee accommodates larger diameter pipes (0.75 inches) versus the 0.5-inch 1/2 version. Both use identical press-connect installation. Choose based on your system's pipe dimensions.

Q: Is special equipment needed to install Megapress Tee fittings?

A: Installation requires a certified Megapress pressing tool for secure joints. No flame or soldering is needed. Follow manufacturer torque specifications for optimal results.

Q: Are Megapress Tee fittings reusable after installation?

A: No, Megapress Tee fittings are single-use due to permanent deformation during pressing. Cutting and replacing is required for modifications. Plan layouts carefully before installation.