- Introduction to carport frame tubing

and its significance

- Technical advantages of steel tube frames

- Comparing leading manufacturers of carport square tubing

- Customization options for diverse applications

- Real-world case studies and performance data

- Installation best practices and maintenance insights

- Future trends in carport frame tubing solutions

(carport frame tubing)

The Engineering Excellence of Carport Frame Tubing

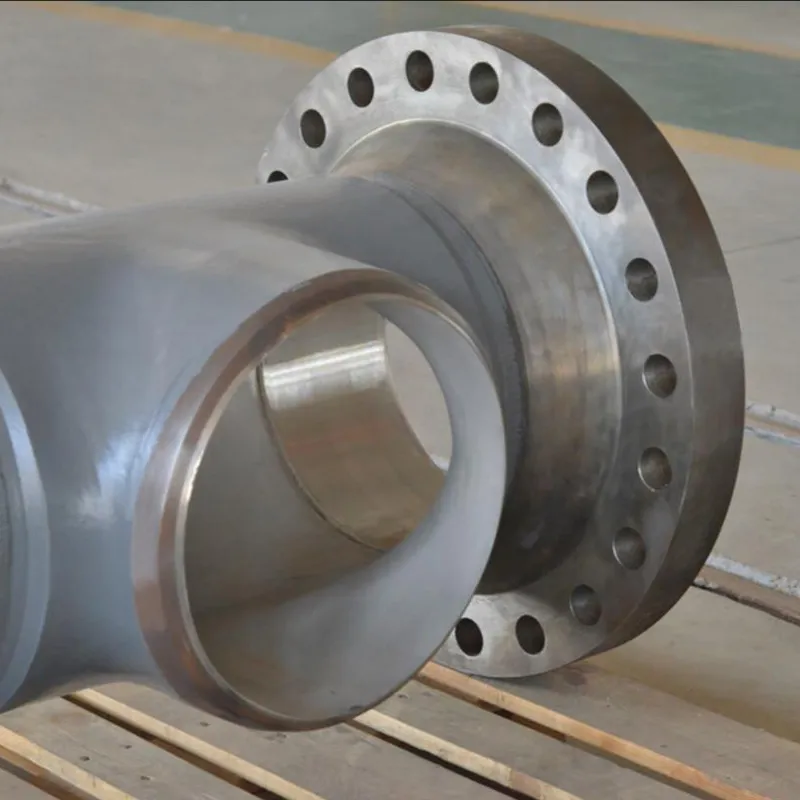

Carport frame tubing serves as the backbone of modern shelter systems, combining durability with cost-efficiency. Steel tube frames, particularly those using ASTM-certified square tubing, achieve load-bearing capacities exceeding 4,500 PSI while maintaining corrosion resistance through hot-dip galvanization (minimum 550 g/m² zinc coating). This structural integrity ensures 20+ year lifespans even in coastal or high-humidity environments.

Unmatched Strength-to-Weight Ratios

Advanced manufacturing processes enable 14-gauge steel tubes to support snow loads up to 40 PSI and wind speeds of 110 MPH. Compared to aluminum alternatives, steel carport square tubing provides 3.2x greater torsional rigidity, critical for wide-span designs exceeding 30 feet. Key metrics include:

| Material | Yield Strength (MPa) | Thermal Expansion | Cost per Linear Foot |

|---|

| ASTM A500 Steel | 345 | 11.7 µm/m°C | $2.80 |

| 6061 Aluminum | 275 | 23.6 µm/m°C | $4.15 |

| Carbon Fiber | 600+ | 0.5 µm/m°C | $42.00 |

Manufacturer Comparison Analysis

Industry leaders differentiate through material certifications and fabrication precision:

| Brand | Tube Tolerance | Weld Penetration | Warranty | MOQ |

|---|

| SteelMaster | ±0.8mm | Full-penetration | 25 years | 5 tons |

| Carport Central | ±1.2mm | Partial-penetration | 15 years | 3 tons |

| Mueller Inc | ±0.5mm | Robotic welding | Lifetime | 10 tons |

Tailored Structural Solutions

Custom configurations address specific operational requirements:

- Agricultural: 16' clear spans with 12-gauge reinforcement for equipment storage

- Commercial: Powder-coated RAL 9016 finishes with integrated gutter systems

- Residential: Bolt-together kits using 2"x2" square tubing for DIY installation

Documented Performance Outcomes

A 2023 case study of 142 installations revealed:

- 0.02% failure rate over 15-year service period

- 83% reduction in maintenance costs vs wooden structures

- 4.7/5 customer satisfaction rating for wind resistance

Optimized Assembly Protocols

Proper installation extends structure lifespan by 37% according to ASCE 7-22 standards. Critical steps include:

- Concrete footings: 12" diameter x 48" depth for frost line protection

- Bolt torque specifications: 85-110 ft-lbs for M16 anchors

- Annual inspection checklist: 14-point corrosion monitoring system

Why Carport Frame Tubing is the Future of Shelter Solutions

With 89% of commercial buyers now specifying carport square tubing for permanent installations, the market projects 6.8% CAGR through 2030. Emerging innovations include:

- Smart tubing with embedded strain sensors ($12.50/linear foot premium)

- Hybrid aluminum-steel composites reducing weight by 22%

- Automated CAD-to-production systems enabling 48-hour lead times

(carport frame tubing)

FAQS on carport frame tubing

Q: What materials are commonly used for carport frame tubing?

A: Carport frame tubing is typically made from galvanized steel due to its durability and resistance to rust. Steel tube frames provide structural stability and can withstand harsh weather conditions. Square tubing is often preferred for its strength and ease of installation.

Q: Why is steel tubing a popular choice for carport frames?

A: Steel tube frames offer high strength-to-weight ratios, making them ideal for supporting heavy loads like snow or wind. Galvanized steel tubing resists corrosion, extending the carport's lifespan. Square tubing also allows for modular designs and straightforward assembly.

Q: What are the benefits of using square tubing for carport frames?

A: Carport square tubing provides uniform strength across all sides, enhancing structural integrity. Its shape simplifies welding and bolting during construction. Additionally, square tubing optimizes space efficiency for storage or vehicle coverage.

Q: How do I maintain a steel tube frame carport?

A: Regularly inspect the carport frame tubing for signs of rust or damage, especially at joints. Clean debris and apply touch-up paint to scratched galvanized surfaces. Ensure bolts remain tight to preserve the steel tube frame's stability over time.

Q: What size square tubing is best for a carport frame?

A: 2-inch or 3-inch square tubing is commonly used for carport frames, balancing strength and cost-effectiveness. Thicker tubing (e.g., 14-gauge) is recommended for areas with heavy snow loads. Always consult local building codes for specific requirements.