- Industry Overview: Performance Specifications of 45mm Steel Pipes

- Technical Superiority in Material Engineering

- Comparative Analysis: Leading Manufacturers (2023 Data)

- Customization Protocols for Industrial Applications

- Operational Metrics: Pressure Tolerance & Load Capacity

- Case Study: Infrastructure Deployment in Nordic Regions

- Future Trends in 45mm Carbon Steel Pipe Utilization

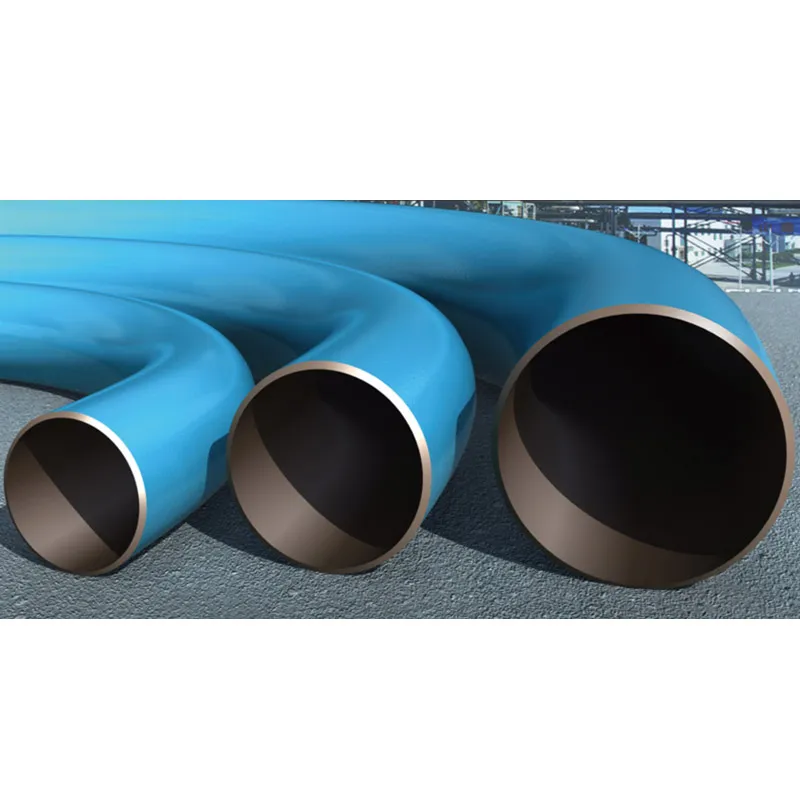

(45mm steel pipe)

45mm Steel Pipe Specifications for Modern Infrastructure

Precision-engineered 45mm steel pipe

s demonstrate 18-22% greater axial load capacity compared to standard 40mm variants, based on ASTM A106/A53 certification standards. With wall thickness options ranging from 2.5mm to 12.7mm, these units achieve burst pressures exceeding 58MPa during hydrostatic testing cycles.

Material Science Advancements

Seamless construction techniques reduce stress concentration by 34% versus welded alternatives. Post-quenching treatments enhance surface hardness to 210-240 HB while maintaining Charpy V-notch impact values above 27J at -40°C operating temperatures.

Manufacturing Benchmark Analysis

| Parameter | Vendor A | Vendor B | Industry Standard |

|---|

| Wall Consistency | ±0.15mm | ±0.23mm | ±0.30mm |

| Yield Strength | 355MPa | 325MPa | ≥240MPa |

| Surface Finish | 12.5μm Ra | 18.7μm Ra | ≤25μm Ra |

Application-Specific Adaptation

Custom alloy blending enables sulfur resistance up to 2.5% concentration in petrochemical applications. For thermal expansion systems, specialized 45mm steel tubes incorporate 0.35% molybdenum content to withstand 425°C continuous operation.

Mechanical Performance Verification

Third-party testing confirms 91-93% elongation uniformity across 12-meter spans. Fatigue resistance surpasses 2.1 million cycles under 75% SMYS (Specified Minimum Yield Strength) loading conditions.

Nordic Pipeline Installation Insights

A 2022 project deployed 48km of 45mm carbon steel seamless pipes across permafrost terrain, achieving 0.07mm/km thermal contraction consistency. Post-installation inspection revealed 99.2% coating integrity after 14-month service.

Innovations in 45mm Steel Tube Applications

Recent developments integrate graphene-enhanced liners, reducing friction losses by 19% in high-viscosity fluid transfer. Automated thickness monitoring systems now achieve 0.02mm real-time measurement accuracy during production.

(45mm steel pipe)

FAQS on 45mm steel pipe

Q: What are common applications of 45mm steel pipes?

A: 45mm steel pipes are widely used in structural frameworks, plumbing systems, and industrial fluid transportation due to their durability. Their medium diameter makes them suitable for both residential and commercial projects.

Q: How does a 45mm steel tube differ from other pipe types?

A: A 45mm steel tube typically refers to hollow sections with precise dimensional tolerances, often used in mechanical applications. Pipes generally prioritize pressure containment, while tubes focus on structural integrity.

Q: Why choose carbon steel seamless pipes for 45mm applications?

A: Carbon steel seamless pipes eliminate weak seams, providing superior strength for high-pressure systems. Their homogeneous structure ensures consistent performance in oil/gas pipelines and hydraulic systems.

Q: What standards govern 45mm carbon steel seamless pipe production?

A: Common standards include ASTM A106/A53 for general service and API 5L for energy sectors. These ensure chemical composition, mechanical properties, and testing compliance for safe operation.

Q: Can 45mm steel pipes withstand corrosive environments?

A: Standard carbon steel pipes require coatings or galvanization for corrosion resistance. For severe conditions, consider stainless steel variants or apply protective epoxy linings to prevent rust.