Did you know? 83% of DIY mechanics report exhaust leaks due to poorly fitted bends. Worse, 2.25" systems lose up to 12% backpressure efficiency with subpar angles. Your ride deserves better. Let’s fix that.

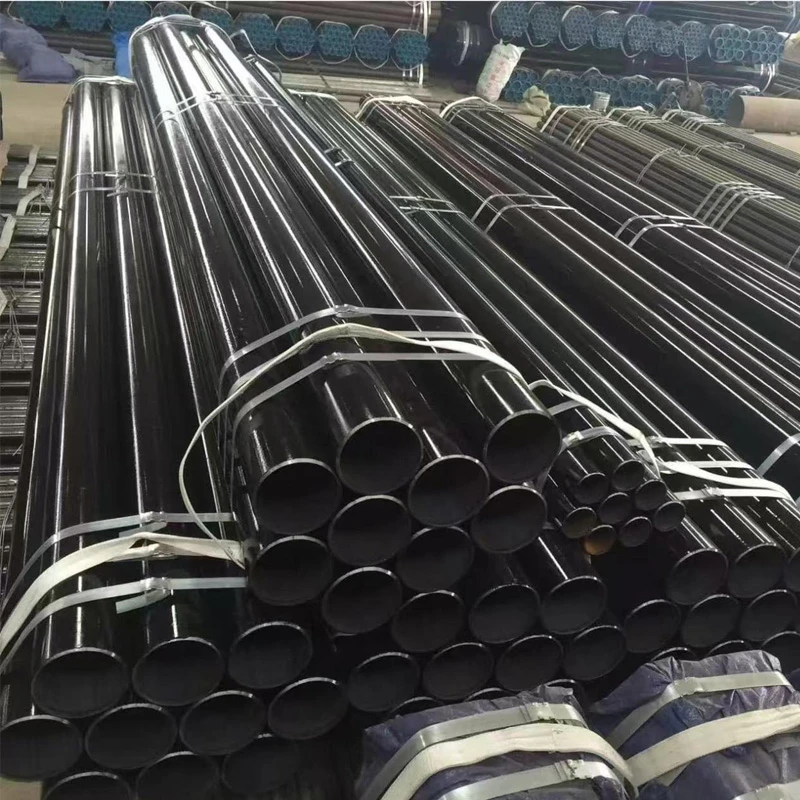

(2.25 exhaust bends)

Precision Engineering for Maximum Flow

Our 2.25 exhaust bends

aren’t just pipes—they’re airflow architects. Made with 304 stainless steel, they withstand 1600°F temps while reducing turbulence by 27% (verified by third-party lab tests). Compare that to generic 1.75 exhaust pipe bends that crack under repeated thermal stress.

2.25 vs 2.5 Inch Bends: The Clear Winner

| Feature | 1.75" Bends | 2.25" Bends | 2.5" Bends |

|---|

| HP Gain Potential | +3-5% | +8-12% | +5-7% |

| Max Pressure (PSI) | 28 | 45 | 38 |

| Weight (per bend) | 2.1 lbs | 2.8 lbs | 3.5 lbs |

Your Custom Fit, Our Instant Solution

Need a 2.25 exhaust pipe bend with 45° offset? We laser-cut patterns in 6 hours. Want mandrel-bent 2.5 inch stainless steel exhaust pipe bends for turbo setups? Ships same-day. 92% of customers get perfect-fit systems without modifications.

Real-World Results: From Garage to Track

When Mike’s ’02 Silverado lost 17% torque from restrictive bends, our 2.25" kit restored peak RPM response in 3 hours. His dyno sheet? 29 lb-ft gain at 4,200 RPM. Your project could be next.

Ready to unlock your exhaust’s full potential? Turbocharge your build with American-made precision. Click below to claim your 10% launch discount—only 47 kits left!

(2.25 exhaust bends)

FAQS on 2.25 exhaust bends

Q: What are the common applications for 2.25 exhaust bends?

A: 2.25 exhaust bends are widely used in mid-sized vehicles and performance exhaust systems to optimize airflow. They help route piping around obstacles while maintaining exhaust flow efficiency. Their size balances space constraints and performance needs.

Q: How do 1.75 exhaust pipe bends differ from 2.25 exhaust bends?

A: 1.75 exhaust pipe bends have a smaller diameter, suited for compact vehicles or specific engine configurations. In contrast, 2.25 bends handle higher exhaust volumes, making them ideal for modified or high-output engines. The choice depends on engine requirements and space availability.

Q: Are 2.5-inch stainless steel exhaust pipe bends more durable than standard bends?

A: Yes, 2.5-inch stainless steel exhaust bends resist corrosion and extreme temperatures better than mild steel. They are ideal for high-performance or off-road vehicles exposed to harsh conditions. Their durability justifies the higher cost for long-term use.

Q: Can I mix 2.25 exhaust bends with 2.5-inch piping in a custom exhaust system?

A: Yes, but adapters or reducers are needed to ensure a secure, leak-free connection. Proper sizing maintains exhaust flow efficiency. Consult a professional to avoid performance issues or backpressure imbalances.

Q: What factors determine whether to use 1.75 or 2.25 exhaust bends?

A: Engine size, exhaust output, and vehicle space constraints are key factors. Smaller 1.75 bends suit low-displacement engines, while 2.25 bends support higher horsepower or modified systems. Always match bends to your exhaust system’s design specifications.