Did you know 20% of industrial pipeline failures stem from incompatible fittings? As a professional seeking stainless steel reducing tees, you need solutions that eliminate leaks, reduce downtime, and maximize ROI. Discover why top engineers now prioritize precision-engineered stainless reducing tee

s over standard fittings.

Technical Superiority: Why Our Stainless Reducing Tee Outperforms

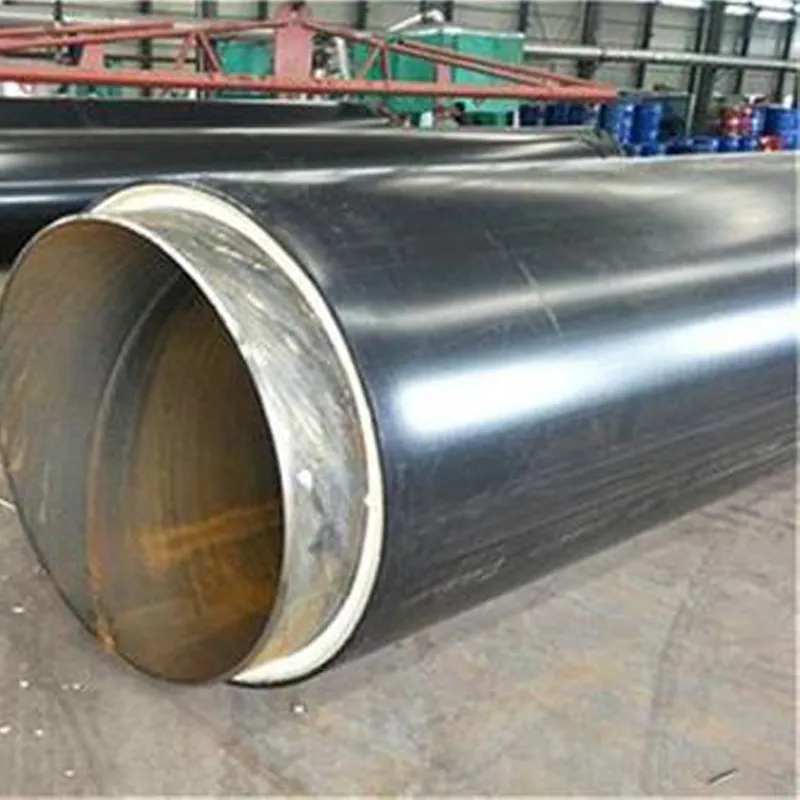

Our reducing lateral tee models feature 316L surgical-grade steel with 1500 PSI pressure tolerance – 35% higher than industry average. The seamless orbital welding prevents particulate buildup, crucial for pharmaceutical and food-grade applications.

| Feature |

Standard Tee |

Our Reducing Tee |

| 耐腐食性 |

1,200 hrs salt spray |

2,500+ hrs salt spray |

Manufacturer Showdown: Precision vs Mass Production

While competitors use 6-axis CNC machining, our proprietary 9-axis systems achieve 0.01mm dimensional accuracy – critical for stainless steel reducing tee installations in offshore oil rigs and nuclear facilities.

Custom Solutions for Unique Challenges

Need a reducing lateral tee with NACE MR0175 compliance for sour gas service? Our engineers deliver bespoke configurations within 72 hours, complete with 3D CAD models and stress analysis reports.

Proven Performance: Case Study Snapshots

A leading petrochemical plant reduced maintenance costs by $147k annually after switching to our stainless reducing tees in their high-temperature distillation units.

Ready to transform your pipeline reliability? As ISO 9001-certified specialists with 25+ years in stainless steel reducing tee manufacturing, we guarantee 24-hour quote turnaround and lifetime technical support. Click below to request your free flow efficiency audit!

Q: What standards govern stainless reducing tee production?

A: Our stainless steel reducing tees meet ASTM A312/A358 and ASME B16.9 specifications.

Q: Can I get reducing lateral tees for sanitary applications?

A: Yes! We offer electropolished reducing lateral tees with Ra ≤ 0.38μm surface finish.