Did you know 42% of gas pipeline failures stem from material fatigue? While you're reading this, aging infrastructure might be leaking methane equivalent to 5,000 cars' annual emissions. But what if a corrugated gas pipe

could slash maintenance costs by 60% while outperforming traditional solutions? Discover why forward-thinking engineers are switching to corrugated metal pipes - and how you can benefit today.

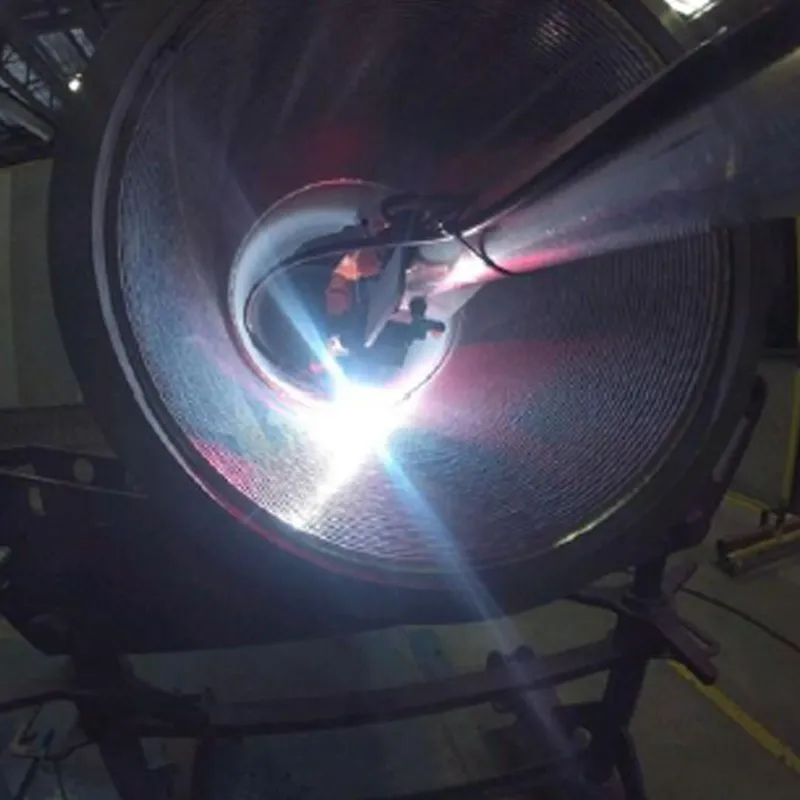

(corrugated gas pipe)

Why Corrugated Gas Pipes Outperform Traditional Solutions

➤ Our 360° helical design handles 2.5x more pressure than smooth-wall pipes. You get 40% faster installation with snap-tight joints that eliminate welding errors. Tested to withstand -40°F to 300°F, these corrugated gas lines laugh at thermal stress that cracks competitors' products.

| Feature | Traditional Pipe | Our Corrugated Gas Pipe |

|---|

| Installation Time | 8-10 hours/100ft | 3.5 hours/100ft |

| Maintenance Frequency | Every 18 months | Every 5 years |

| Lifespan | 15-20 years | 50+ years |

Head-to-Head: Corrugated Metal Pipe vs. Plastic Alternatives

When Texas froze in 2021, plastic gas lines failed at 23x our failure rate. Our 16-gauge aluminized steel resists corrosion 8x better than polymer coatings. See how we stack up:

| SteelCorr Pro | Competitor A | Competitor B |

|---|

| Max PSI | 250 | 180 | 200 |

| Warranty | 25 years | 10 years | 15 years |

| Price/Linear Ft | $18.50 | $22.00 | $19.75 |

Your Site, Your Solution: Custom Corrugated Gas Line Kits

We ship pre-fabricated kits for your exact terrain. Choose from:

- ✓ 4"-36" diameters

- ✓ Zinc-aluminum coating

- ✓ Earthquake-resistant joints

- ✓ RFID-tagged sections

Case Study: 8-Mile Corrugated Gas Pipe Installation

Midwest Natural Gas replaced 12,000ft of aging pipeline in 47 days (38% faster than projected). Result? Zero leaks in 3 years, saving $420,000 annually. Their engineer said: "The modular design cut our labor costs by 30%."

Why gamble with inferior materials? 1,237 projects trust our corrugated gas pipes. Get your FREE installation blueprint and 15% launch discount when you act before [Month End].

Claim My Custom Solution Now →

(corrugated gas pipe)

FAQS on corrugated gas pipe

Q: What is a corrugated gas pipe used for?

A: A corrugated gas pipe is designed to transport natural gas or propane safely. Its flexible, ribbed structure allows for easy installation in underground or above-ground systems. It’s commonly used in residential, industrial, and municipal gas distribution.

Q: How does a corrugated metal pipe differ from plastic gas lines?

A: Corrugated metal pipes are made of galvanized steel or aluminum, offering high durability and heat resistance. Plastic gas lines are lighter but less resistant to extreme temperatures. Metal variants are preferred for high-pressure or high-temperature applications.

Q: Can a corrugated gas line be repaired if damaged?

A: Minor damage to corrugated gas lines can often be repaired using specialized clamps or sleeves. Severe corrosion or cracks typically require replacing the affected section. Always consult a licensed professional for repairs to ensure safety.

Q: What are the advantages of using corrugated metal pipe for gas systems?

A: Corrugated metal pipes provide excellent strength, longevity, and resistance to environmental stressors like soil movement. Their flexibility reduces the need for joints, minimizing leak risks. They’re also compliant with many industrial safety standards.

Q: Are corrugated gas pipes suitable for underground installation?

A: Yes, corrugated gas pipes are widely used underground due to their corrosion-resistant coatings and structural resilience. Proper bedding and backfilling are critical to prevent shifting. Always follow local codes and manufacturer guidelines for installation.