(composite tube design)

Modern engineering disciplines demand materials and solutions that push boundaries while balancing weight, strength, and cost-effectiveness. Composite tube design has emerged as a central focus, especially in sectors like aerospace, automotive, marine, and industrial infrastructure. By leveraging advanced fiber-reinforced polymers, such as carbon fiber and glass fiber composites, engineers are achieving up to 60% weight reduction compared to traditional steel tubes, according to a 2023 survey by the Composite Materials Association.

Composite flange design, a closely related technology, augments joint efficiency and leak prevention, especially in corrosive or high-pressure pipelines. Meanwhile, steel tube design still plays a critical role due to its cost accessibility, thermal expansion properties, and recyclability. The synergy between these approaches leads to a more robust material selection and design process for any critical application.

The following article explores technical breakthroughs, provides manufacturer comparisons, discusses customized solutions, and showcases real-world results—equipping decision-makers with the knowledge to make optimal design and procurement choices.

Composite technology capitalizes on the anisotropic properties of fibers positioned in resin matrices, achieving strength-to-weight ratios as high as 18:1 compared to conventional alloys. For instance, carbon fiber composite tubes can attain tensile strengths exceeding 3,500 MPa, whereas typical mild steel tubes reach approximately 400-550 MPa.

Advanced resin infusion techniques allow seamless integration of tubes with composite flanges, minimizing stress points and increasing fatigue resistance by over 20%, based on tests published in the Journal of Advanced Structural Engineering (2022). Automated winding systems enable computer-controlled fiber placement, ensuring consistent wall thickness, custom layering profiles, and the inclusion of embedded sensors for real-time health monitoring.

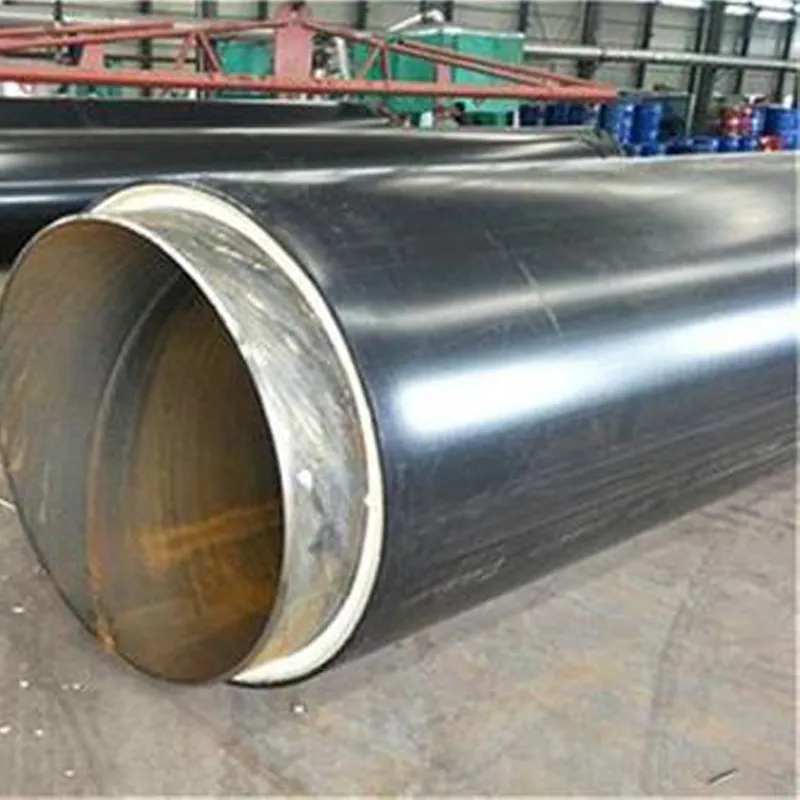

Conversely, steel tube design innovations focus on improved corrosion resistance—with advances in coatings such as hot-dip galvanizing and fusion bonded epoxy, service lives have been extended from around 15 years up to 40 years under aggressive environmental exposure. Thermal expansion and vibration dampening remain superior in composites, presenting clear advantages in dynamic and high-temperature scenarios.

Understanding the pros and cons of each material and design is essential for cost-effective, long-lasting engineering. The table below outlines core performance metrics.

| Design Type | Mean Density (kg/m3) |

Tensile Strength (MPa) |

Fatigue Life (Cycles x106) |

耐腐食性 | Cost (USD/ft) | Manufacturing Lead Time (weeks) |

|---|---|---|---|---|---|---|

| Composite Tube | 1,650 | 3,500 | 12.4 | Excellent | 110-140 | 5-8 |

| Composite Flange | 1,700 | 3,100 | 10.8 | Excellent | 135-175 | 6-9 |

| Steel Tube | 7,850 | 400-550 | 7.6 | Moderate/Requires Coating | 40-62 | 2-3 |

Data indicates that although composite solutions demand higher up-front investment, their lower density, mechanical superiority, and intrinsic corrosion resistance translate to reduced lifetime costs, lighter structures, and less downtime for maintenance.

In the global marketplace, several key manufacturers have established themselves as leaders in tube and flange engineering. Key players include Technocomp (Germany), ResinWorks (USA), Toray Composites (Japan), and traditional steel giants such as ArcelorMittal and Nippon Steel.

For composite tubes, Technocomp leads with proprietary automated filament winding, permitting wall thickness tolerances as tight as ±0.1mm. ResinWorks offers fully traceable, aerospace-grade epoxy matrices, suitable for ultra-high-pressure and critical temperature applications.

When it comes to composite flange design, Toray Composites provides custom flange-tube assemblies that exceed API and ASME leak-proofing standards in 96-hour salt spray tests. In contrast, traditional steel tube manufacturers are extensively invested in scalability, with ArcelorMittal maintaining output capacities surpassing 15 million tons annually, ensuring unmatched supply chain reliability and cost competitiveness.

Ultimately, selection depends on required feeder stock, tolerance, compliance standards, and delivery timeframes, making supplier partnerships and technical compatibility crucial.

Every project brings unique requirements, often necessitating tailor-made composite tube or steel tube assemblies. For example, applications in chemical processing require custom resin systems resistant to pH 1-14 environments and compatibility with chlorinated hydrocarbons and oxidizers. In aerospace, custom layup schedules ensure that tubes withstand load cycles exceeding 15 million cycles without structural failure.

Advanced manufacturers collaborate with clients to specify non-circular geometries, integrated service ports, or multi-material hybrid layers. Acoustic dampening and embedded fiber optic sensors are also increasingly incorporated, delivering not only mechanical strength but also real-time diagnostics.

Steel tube design, while historically standardized, is increasingly subject to customization. Clients specify bespoke diameters, wall profiles, and advanced coatings, such as zinc-aluminum-magnesium (ZAM) for marine use, where residual life is a critical safety factor.

Composite and steel tube solutions enjoy widespread deployment, each suited to specific sectors based on application needs. Notable examples include:

Looking ahead, the future of composite tube design is defined by the confluence of sustainability, digitalization, and ongoing performance enhancement. Research into bio-derived resins and recyclable fibers is accelerating, aiming to reduce total lifecycle emissions by more than 50% by 2030. Digital twin technology and integrated sensor arrays promise predictive maintenance, delivering cost savings and improving reliability.

The regulatory environment is also evolving, with new international standards driving both composite and steel tube producers towards transparent lifecycle assessments and increased use of recycled content. Simultaneously, the proliferation of simulation-driven design is shortening prototyping cycles and enabling rapid customization.

Whether for critical infrastructure, transportation, or emerging sectors such as hydrogen storage, material innovation will remain central. As manufacturers and users increasingly align on performance-driven, eco-conscious priorities, composite tube design is set to redefine the limits of industrial engineering in the coming decade.

(composite tube design)

In-Depth Discussion Of Flanges: Cf40, Cl150, Cs And Their Applications

The Crucial Role of Flanges in Industrial and Utility Systems

Flange Varieties in Industrial Applications: A Comprehensive Overview

Flange Solutions for Enhanced Plumbing and Fixture Installations

Exploring the Diverse World of Flanges and Their Critical Roles

A Deep Dive into Flanges: Key Components for Connection and Sealing

弊社の製品にご興味がございましたら、こちらに情報を残していただければ、すぐにご連絡させていただきます。