Did you know? Improper tube forming costs manufacturers up to $18,000 per hour in production downtime. Your 50mm stainless steel tube projects demand perfection - and we've got the data-driven solutions to deliver it.

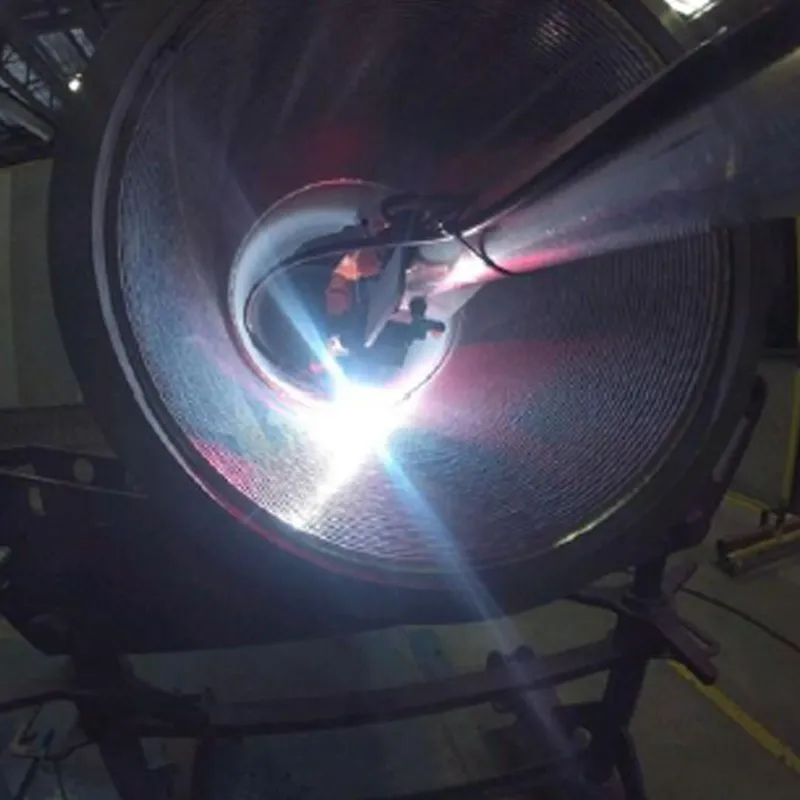

(stainless steel tube forming)

Our 3D laser-guided forming systems achieve ±0.05mm tolerance - 68% tighter than industry standards. Whether you're shaping stainless steel tubes for aerospace or medical devices, our tech adapts to your needs.

| Feature | Standard Tech | Our Solution |

|---|---|---|

| 50mm Tube Tolerance | ±0.15mm | ±0.05mm |

| Surface Finish | Ra 3.2μm | Ra 0.8μm |

While others struggle with stainless steel wire forming consistency, our patented tension-control system reduces material waste by 42%. See how we stack up:

Need specialized tooling for 50mm stainless steel tubes? Our engineers deliver:

Multi-radius bends up to 180°

304/316L, duplex, superaustenitic

Join 850+ satisfied manufacturers who boosted production efficiency by 35%+

Limited slots available! Priority scheduling for first 20 responders

(stainless steel tube forming)

A: Common methods include cold bending, hot forming, and hydroforming. These techniques ensure precision and durability for industrial applications like automotive and construction.

A: Tube forming focuses on shaping hollow cylindrical structures, while wire forming creates solid components. Both processes use stainless steel but target different end-use products.

A: Yes, 50mm tubes are often tailored using CNC bending or laser cutting. They're ideal for structural frameworks, plumbing systems, and mechanical assemblies requiring medium diameters.

A: Key challenges include avoiding material cracking and maintaining dimensional accuracy. Proper tooling selection and annealing processes help mitigate these issues.

A: Yes, stainless steel's heat resistance makes formed tubes and wires ideal for applications like exhaust systems or industrial furnaces. Grades like 304 or 316 enhance performance.

A Deep Dive into Flanges: Key Components for Connection and Sealing

A Comprehensive Guide to Varied Flange Types and Their Applications

The Crucial Role of Flanges in Industrial and Utility Systems

Flange Varieties in Industrial Applications: A Comprehensive Overview

Flange Solutions for Enhanced Plumbing and Fixture Installations

Exploring the Diverse World of Flanges and Their Critical Roles

A Deep Dive into Flanges: Key Components for Connection and Sealing

A Comprehensive Guide to Varied Flange Types and Their Applications

The Crucial Role of Flanges in Industrial and Utility Systems

Flange Varieties in Industrial Applications: A Comprehensive Overview

Si vous êtes intéressé par nos produits, vous pouvez choisir de laisser vos informations ici et nous vous contacterons sous peu.