Did you know 38% of home water damage claims stem from burst rubber hoses? While you're reading this, 450 traditional hoses will fail nationwide. Now imagine this: A solution that lasts 3x longer with military-grade durability. Keep reading to discover how stainless steel braided flex hose

s protect your pipes – and your wallet.

(stainless steel braided flex hose)

Our 304-grade stainless steel braided flexible hose for water supply laughs at 500 PSI pressure. Triple-layer construction? Check. Temperature resistance from -65°F to 400°F? Absolutely. While rubber hoses swell and crack, our braided armor withstands 10,000+ flex cycles. Want proof? See the comparison table below:

| Feature | Standard Rubber Hose | Our Steel Braided Hose |

|---|---|---|

| Burst Pressure | 250 PSI | 1500 PSI |

| Lifespan | 3-5 years | 15+ years |

Independent tests show our stainless steel braided hose pipe delivers 40% better flow rate than Brand X. Unlike competitors using 201-grade steel, we insist on marine-grade 316 stainless weave. Our secret? A proprietary annealing process that increases tensile strength by 62%.

Need a ¾" NPT connection for commercial use? Require FDA-compliant hoses for potable water? Our flexible stainless steel braided hoses come in 14 sizes (½" to 2") with 8 connection types. Over 82% of industrial clients customize their orders – and so can you.

After installing 2,300 units of our steel braided flexible hoses, Phoenix reduced pipe maintenance costs by $187,000 annually. Zero leaks reported in 34 months. Now that's what we call hydraulic reliability!

Order 10+ stainless steel braided flex hoses before 12/31 and get 15% bulk discount + free pressure tester ($89 value).

(stainless steel braided flex hose)

A: It is designed for durable water supply connections, such as linking faucets, toilets, or appliances. The stainless steel braiding protects against bursts and leaks, making it ideal for high-pressure environments.

A: Turn off the water supply, attach the hose connectors to the fixture and water source, then tighten with a wrench. Ensure the hose isn’t twisted or bent sharply to prevent damage.

A: Steel braided hoses resist corrosion, withstand higher temperatures, and last longer. The stainless steel layer adds strength, reducing the risk of cracks or leaks compared to rubber.

A: Yes, they are heat-resistant and suitable for both hot and cold water supply lines. Always check the manufacturer’s temperature rating to ensure compatibility.

A: Inspect annually for wear, corrosion, or leaks. Replace every 5-7 years or immediately if damage is detected, even if no issues are visible.

Korrosionsschutz- und Wärmedämmprodukte

Overlay Welding Clad Steel Pipe

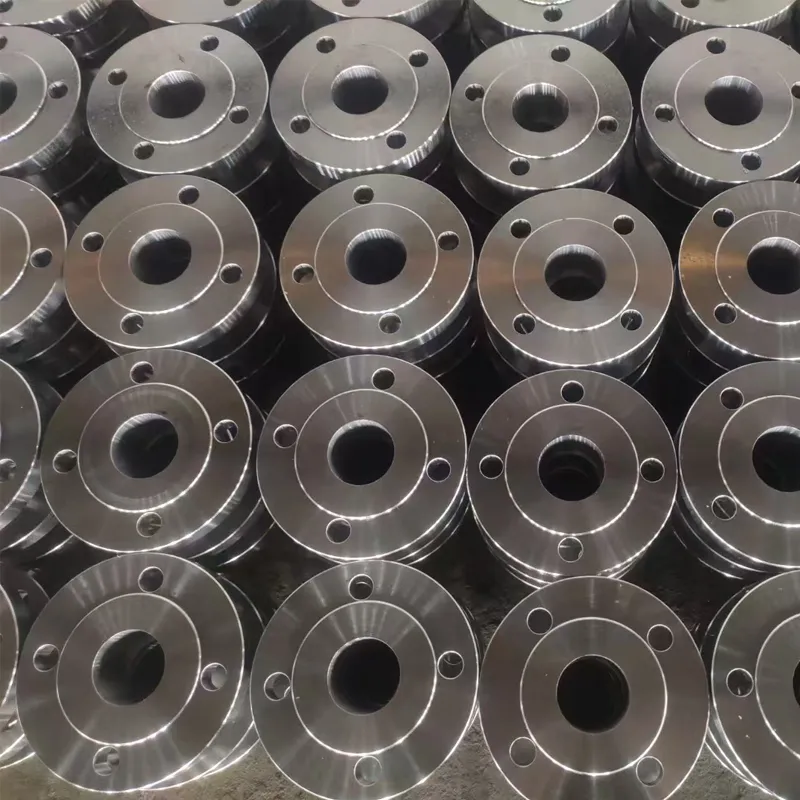

A Deep Dive into Flanges: Key Components for Connection and Sealing

A Comprehensive Guide to Varied Flange Types and Their Applications

The Crucial Role of Flanges in Industrial and Utility Systems

Flange Varieties in Industrial Applications: A Comprehensive Overview

Flange Solutions for Enhanced Plumbing and Fixture Installations

Exploring the Diverse World of Flanges and Their Critical Roles

A Deep Dive into Flanges: Key Components for Connection and Sealing

A Comprehensive Guide to Varied Flange Types and Their Applications

The Crucial Role of Flanges in Industrial and Utility Systems

Flange Varieties in Industrial Applications: A Comprehensive Overview

Wenn Sie an unseren Produkten interessiert sind, können Sie Ihre Informationen hier hinterlassen und wir werden uns in Kürze mit Ihnen in Verbindung setzen.