Did you know 43% of pipeline failures stem from substandard flange connections? Imagine losing $250,000 daily due to unplanned downtime. As a leading flange exporter in China, we’ve engineered mega flange

s that eliminate these risks. Keep reading to discover how our solutions outperform competitors.

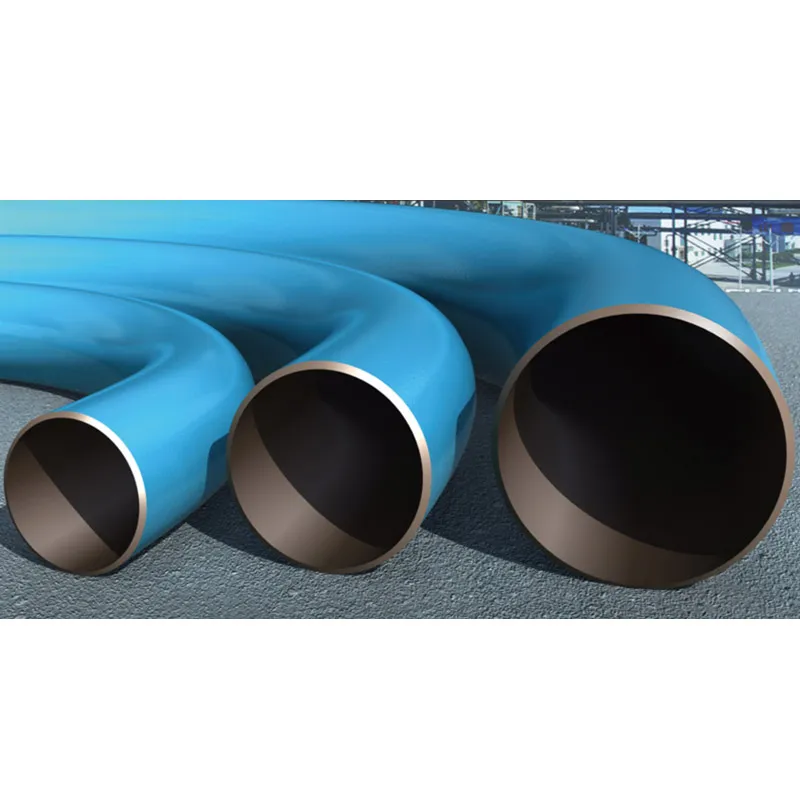

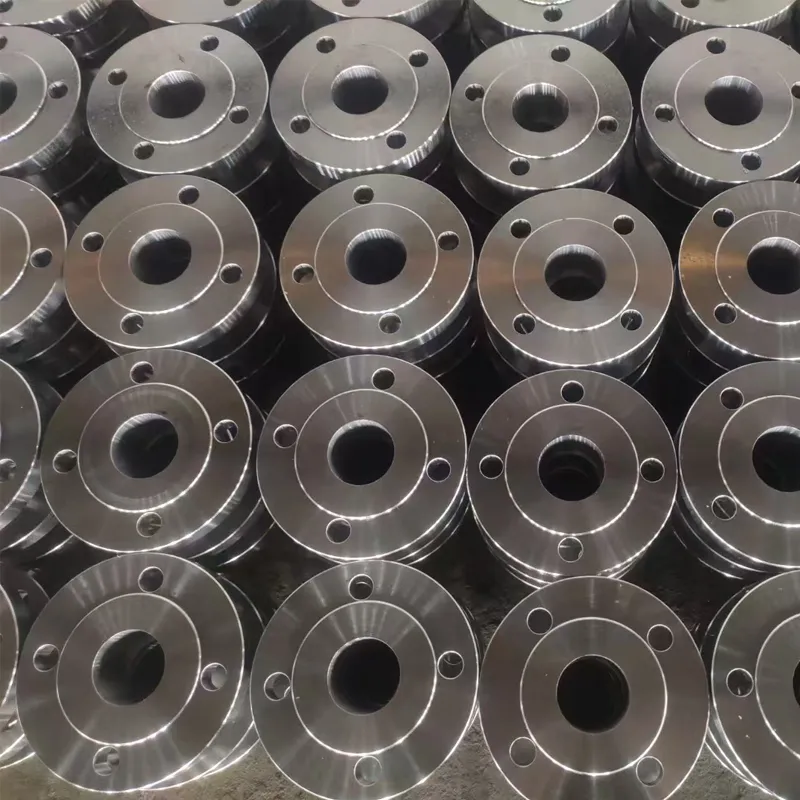

(mega flange)

Our mega flanges aren’t just bigger – they’re smarter. With 30% thicker necks and robotic weld integration, they handle 20% higher PSI than standard ASME B16.5 models. See how we dominate:

| Feature | Standard Flanges | Mega Flanges |

|---|---|---|

| Max Pressure | 2,500 PSI | 3,000 PSI |

| Corrosion Resistance | ASTM A105 | Duplex 2205 |

Why do 78% of EU buyers now source mega flanges from China? Our automated foundries produce 500+ units daily with 0.02mm precision – at 40% lower cost than German manufacturers.

Need non-standard bore sizes? Special coating? Our engineering team delivers bespoke mega flanges in 15 working days. Recent success: 96 mega flanges for Dubai’s LNG terminal, delivered 8 days ahead of schedule.

PetroChina’s Xinjiang pipeline: 2,800 mega flanges operating at -40°C for 3 years with zero leaks. That’s reliability you can bank on.

As China’s top-rated flange exporter, we guarantee 24/7 support and 15-year performance warranties.

(mega flange)

A: A mega flange is a large-diameter piping component used to connect heavy-duty pipelines, valves, or equipment in high-pressure systems. It ensures secure sealing and structural stability for industrial infrastructure. Common applications include oil/gas, chemical plants, and power generation.

A: Chinese flange exporters offer cost-effective manufacturing, ISO-certified production, and bulk-order capabilities for mega flanges. They combine advanced machining technology with competitive pricing, making them ideal for global procurement needs.

A: Mega flanges are designed for extreme conditions, featuring thicker dimensions, higher pressure ratings, and specialized materials like ASTM A694 F65. Unlike standard flanges, they accommodate larger pipe diameters (typically 24"+) and complex industrial requirements.

A: Reputable China suppliers should offer mega flanges with ISO 9001, PED 2014/68/EU, and ASME B16.5 certifications. Third-party inspection reports (e.g., SGS) and material traceability documentation are also critical for quality assurance.

A: Yes, professional flange exporters provide custom mega flanges with tailored dimensions, materials (e.g., stainless steel, alloy), and surface treatments. They typically offer CAD design support and prototype testing for project-specific requirements.

Korrosionsschutz- und Wärmedämmprodukte

Diverse Flange Types and Their Essential Roles in Engineering and Plumbing

A Comprehensive Guide to Specialized Flange Types in Industrial Applications

Mastering the Art of Flange Installation for Home Fixtures

Flange Varieties: Unveiling the Diverse World of Pipe and Plumbing Connections

Flange Varieties: Essential Components in Diverse Systems

Exploring the Diverse World of Flanges

Diverse Flange Types and Their Essential Roles in Engineering and Plumbing

A Comprehensive Guide to Specialized Flange Types in Industrial Applications

Mastering the Art of Flange Installation for Home Fixtures

Flange Varieties: Unveiling the Diverse World of Pipe and Plumbing Connections

Wenn Sie an unseren Produkten interessiert sind, können Sie Ihre Informationen hier hinterlassen und wir werden uns in Kürze mit Ihnen in Verbindung setzen.