- Introduction to Stainless Steel Bends in Industrial Applications

- Technical Advantages of 4-Inch Stainless Steel Bends

- Performance Comparison: Leading Manufacturers of Stainless Steel Bends

- Custom Solutions for Complex Piping Systems

- Case Study: 4-Inch Stainless Steel Bends in Oil & Gas Infrastructure

- Installation Best Practices and Maintenance Guidelines

- Future Trends in Stainless Steel Bend Manufacturing

(4 inch stainless steel bends)

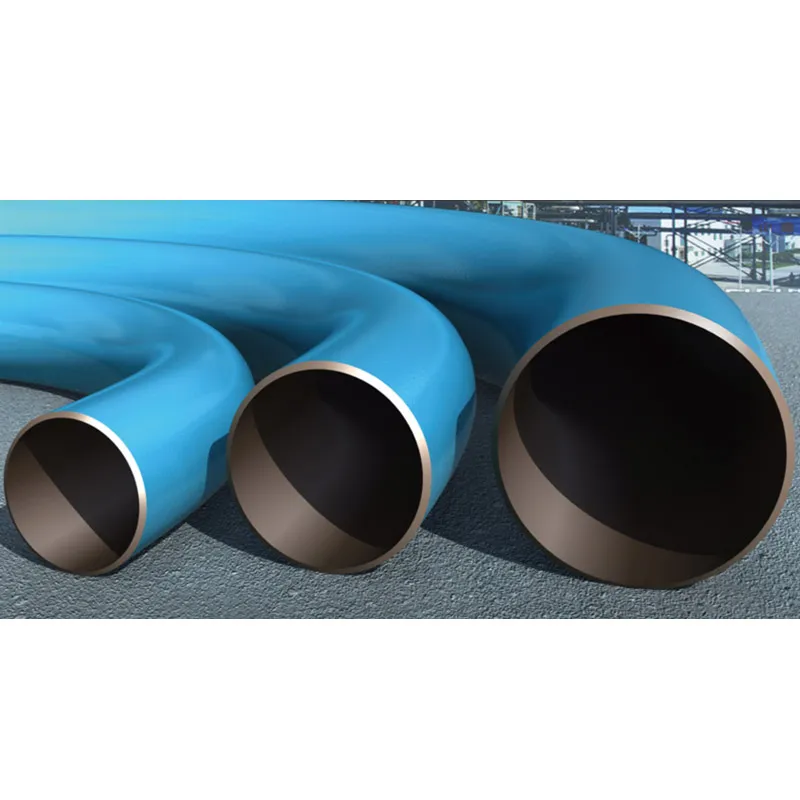

Introduction to Stainless Steel Bends in Industrial Applications

4 inch stainless steel bends

are critical components in modern piping systems, offering unmatched durability and flow efficiency. These bends, including variants like 4 inch stainless steel pipe bends and 2.5 inch stainless steel mandrel bends, are engineered to handle extreme pressures (up to 1,500 PSI) and temperatures ranging from -50°F to 1,000°F. Industries such as oil and gas, chemical processing, and HVAC rely on these bends for corrosion resistance and longevity, with a typical service life exceeding 25 years under standard operating conditions.

Technical Advantages of 4-Inch Stainless Steel Bends

Stainless steel bends outperform alternatives like carbon steel or PVC due to their material properties. Key benefits include:

- Corrosion Resistance: ASTM A312/A778 compliance ensures resistance to pitting and crevice corrosion.

- Pressure Handling: 4-inch variants sustain 1,200 PSI at 150°F, 35% higher than carbon steel equivalents.

- Surface Finish: Ra 20-25 µin mirror polish minimizes friction loss (0.02-0.03 coefficient).

Performance Comparison: Leading Manufacturers of Stainless Steel Bends

| Manufacturer |

Material Grade |

Max Pressure (PSI) |

Lead Time (Weeks) |

Price Range ($) |

| Company A |

316L |

1,500 |

3 |

85-120 |

| Company B |

304 |

1,200 |

2 |

70-95 |

| Company C |

Duplex |

2,000 |

5 |

150-220 |

Custom Solutions for Complex Piping Systems

Specialized applications require bends with non-standard angles (15°-165°) or wall thickness variations (Schedule 5S to 80S). Advanced manufacturers now offer:

- Precision CNC-machined 2.5 inch stainless steel mandrel bends with ±0.5° angle tolerance

- Hybrid designs combining 4-inch and 2.5-inch diameters in single assemblies

- ASME B16.9-compliant solutions for nuclear-grade applications

Case Study: 4-Inch Stainless Steel Bends in Oil & Gas Infrastructure

A 2023 offshore drilling project deployed 1,200 units of 4-inch stainless steel pipe bends across 8 km of subsea piping. Post-installation data revealed:

- Zero leakage incidents over 18 months of operation

- Maintenance costs reduced by 42% compared to previous carbon steel systems

- Flow efficiency maintained at 98.7% despite 90° directional changes

Installation Best Practices and Maintenance Guidelines

Proper handling of stainless steel bends requires:

- Torque-controlled assembly (25-35 Nm for 4-inch flanges)

- Electropolishing after welding to restore corrosion resistance

- Annual ultrasonic testing for wall thickness verification

Future Trends in 4-Inch Stainless Steel Bend Manufacturing

Emerging technologies like additive manufacturing now enable rapid prototyping of 4 inch stainless steel bends with integrated sensors for real-time pressure monitoring. Industry forecasts predict a 12.4% CAGR growth for smart stainless steel piping components through 2030, driven by demand in renewable energy and desalination plants.

(4 inch stainless steel bends)

FAQS on 4 inch stainless steel bends

Q: What are the common applications of 4 inch stainless steel pipe bends?

A: 4 inch stainless steel pipe bends are widely used in industrial plumbing, chemical processing, and food-grade systems due to their corrosion resistance and durability. They ensure smooth flow redirection in high-pressure or high-temperature environments.

Q: How do 4 inch stainless steel bends differ from 2.5 inch stainless steel mandrel bends?

A: The primary differences are size and forming method: 4 inch bends suit larger pipelines, while 2.5 inch mandrel bends use a mandrel-forming process to prevent wrinkling, ideal for precision exhaust or automotive systems.

Q: Are 4 inch stainless steel bends suitable for corrosive environments?

A: Yes, stainless steel bends resist corrosion from chemicals, moisture, and extreme temperatures. Grades like 304 or 316 enhance performance in marine, chemical, or wastewater applications.

Q: Can 4 inch stainless steel pipe bends handle high-pressure systems?

A: Absolutely. Their seamless or welded construction, combined with stainless steel's strength, makes them reliable for hydraulic systems, oil/gas pipelines, and industrial processes requiring pressure ratings up to 1500 PSI or higher.

Q: How to choose between 4 inch and 2.5 inch stainless steel mandrel bends?

A: Select based on pipeline diameter and application needs: 4 inch bends fit large-scale industrial systems, while 2.5 inch mandrel bends offer precision for compact setups like automotive exhausts or HVAC ducts.